Precision machining suppliers deliver critical components with exact specifications for industries requiring high accuracy and reliability. This article explores the capabilities, processes, and benefits of partnering with a precision machining supplier, focusing on technical details and practical applications. With a focus on CNC machining, material selection, and quality assurance, we aim to provide a clear, systematic overview for businesses seeking reliable manufacturing solutions.

What Is Precision Machining?

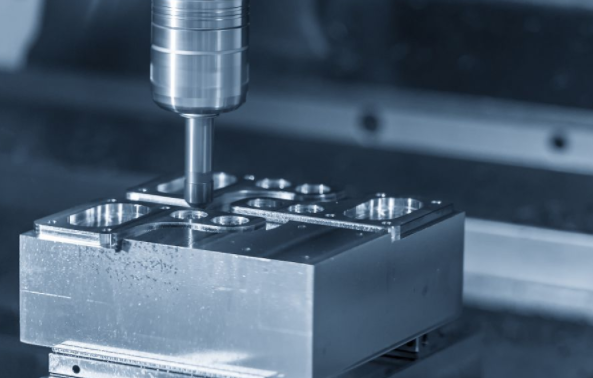

Precision machining involves the use of advanced tools and techniques to create parts with tight tolerances and complex geometries. It relies heavily on computer numerical control (CNC) machines, which ensure consistent accuracy in producing components for industries such as aerospace, automotive, medical, and electronics. A precision machining supplier uses state-of-the-art equipment to meet stringent requirements, often achieving tolerances as tight as ±0.001 inches (±0.0254 mm).

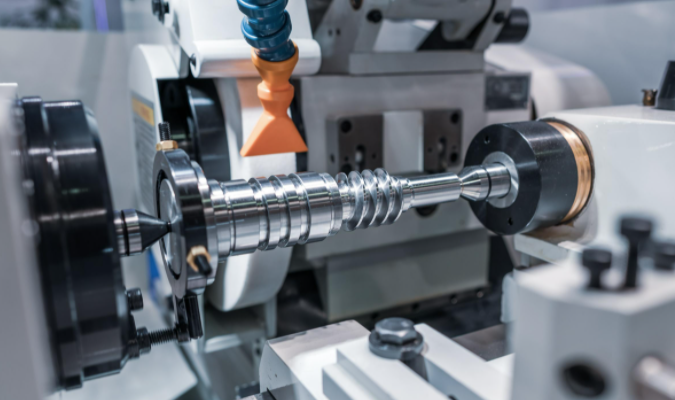

The process includes milling, turning, drilling, and grinding, performed on materials like stainless steel, aluminum, titanium, and engineering plastics. Each operation is programmed to remove material precisely, ensuring the final part meets exact specifications. For example, a CNC milling machine can produce intricate features like slots, pockets, and threads with surface finishes as fine as Ra 0.4 µm.

Key Capabilities of a Precision Machining Supplier

A reliable precision machining supplier offers a range of capabilities to meet diverse industry needs. These include multi-axis CNC machining, material versatility, and quality control systems. Below is a detailed breakdown of these capabilities.

Multi-Axis CNC Machining

Modern precision machining suppliers utilize multi-axis CNC machines, such as 3-axis, 4-axis, and 5-axis systems, to produce complex parts in a single setup. For instance, 5-axis machining allows simultaneous movement along five axes, enabling the production of intricate geometries like turbine blades or orthopedic implants. This reduces setup time and improves accuracy by minimizing repositioning errors.

Key specifications for multi-axis CNC machining include:

- Positional Accuracy: ±0.0002 inches (±0.005 mm)

- Repeatability: ±0.0001 inches (±0.0025 mm)

- Spindle Speed: Up to 30,000 RPM for high-speed cutting

- Work Envelope: Up to 40 x 20 x 20 inches (1016 x 508 x 508 mm)

Material Versatility

Precision machining suppliers work with a wide range of materials to meet specific application requirements. Common materials include:

| Material | Properties | Applications |

|---|---|---|

| Stainless Steel (316/304) | Corrosion-resistant, high strength | Medical devices, marine components |

| Aluminum (6061/7075) | Lightweight, excellent machinability | Aerospace parts, automotive frames |

| Titanium (Grade 5) | High strength-to-weight ratio, biocompatible | Aerospace fasteners, surgical implants |

| PEEK | High temperature resistance, chemical inertness | Medical and semiconductor components |

Material selection is guided by application-specific requirements, such as mechanical strength, thermal stability, or chemical resistance. Suppliers often provide material certifications to ensure compliance with industry standards like ASTM or ISO.

Quality Assurance Systems

Quality assurance is critical in precision machining to ensure parts meet specifications. Suppliers implement rigorous inspection processes using tools like coordinate measuring machines (CMM), laser scanners, and surface profilometers. For example, a CMM can measure dimensional accuracy to within ±0.0001 inches (±0.0025 mm).

Suppliers also adhere to certifications such as ISO 9001 for general quality management and AS9100 for aerospace-specific requirements. These certifications ensure consistent quality and traceability throughout the production process.

Applications of Precision Machining

Precision machining suppliers serve industries with demanding requirements for accuracy and durability. Below are key applications, with specific examples of components and their technical requirements.

Aerospace Industry

In aerospace, precision machining is used to produce components like landing gear parts, engine components, and structural fittings. For example, a titanium turbine blade may require:

- Tolerance: ±0.0005 inches (±0.0127 mm)

- Surface Finish: Ra 0.8 µm or better

- Material: Ti-6Al-4V (Grade 5 titanium)

- Certification: AS9100 compliance

These components must withstand extreme temperatures and stresses, making precision and material integrity critical.

Medical Industry

Medical devices, such as surgical instruments and implants, require biocompatible materials and ultra-precise machining. For instance, a hip implant may involve:

- Material: Cobalt-chromium or PEEK

- Tolerance: ±0.0002 inches (±0.005 mm)

- Surface Finish: Ra 0.2 µm for smooth articulation

- Certification: ISO 13485 compliance

Precision machining ensures these components meet strict regulatory standards while maintaining functionality.

Automotive Industry

In automotive applications, precision machining is used for engine parts, transmission components, and suspension systems. A typical example is a fuel injector nozzle, requiring:

- Material: Stainless steel (17-4 PH)

- Tolerance: ±0.0003 inches (±0.0076 mm)

- Hole Diameter: 0.005 inches (0.127 mm)

- Surface Finish: Ra 0.6 µm

These specifications ensure optimal performance and fuel efficiency in high-performance vehicles.

Benefits of Partnering with a Precision Machining Supplier

Choosing the right precision machining supplier offers several advantages, particularly for businesses requiring high-quality components. These benefits include:

Consistency and Reliability

Suppliers with advanced CNC systems and quality control measures deliver consistent results. Automated processes reduce human error, ensuring each part meets specifications. For example, a supplier producing 10,000 units of a component can maintain dimensional consistency within ±0.001 inches across the entire batch.

Cost Efficiency

By outsourcing to a precision machining supplier, businesses avoid the capital costs of purchasing and maintaining CNC equipment. Suppliers also optimize material usage, reducing waste. For instance, nesting software can maximize material yield, lowering costs for high-value materials like titanium.

Scalability

Precision machining suppliers can scale production to meet varying demand, from prototypes to high-volume runs. This flexibility is critical for industries like electronics, where product lifecycles are short and demand fluctuates.

Choosing the Right Precision Machining Supplier

Selecting a precision machining supplier requires careful evaluation of their capabilities, experience, and certifications. Below are key factors to consider, presented in a structured format.

| Criteria | Description | Why It Matters |

|---|---|---|

| Equipment | Modern CNC machines (e.g., 5-axis, Swiss-type lathes) | Ensures complex geometries and tight tolerances |

| Certifications | ISO 9001, AS9100, ISO 13485 | Guarantees quality and industry-specific compliance |

| Experience | Proven track record in your industry | Reduces risk of errors and delays |

| Inspection | Advanced tools like CMM and laser scanners | Ensures parts meet specifications |

Communication and Support

A supplier should offer clear communication and technical support, including detailed quotes, progress updates, and post-delivery assistance. For example, providing CAD drawings or material test reports can streamline collaboration.

Common Issues in Precision Machining

While precision machining suppliers strive for perfection, certain challenges can arise. Addressing these proactively ensures better outcomes.

Material Variability

Differences in material batches, such as variations in hardness or grain structure, can affect machining outcomes. Suppliers mitigate this by sourcing from certified vendors and conducting material testing before production.

Tolerance Stack-Up

In assemblies with multiple components, small deviations in individual parts can accumulate, leading to fitment issues. Suppliers use statistical process control (SPC) to monitor tolerances and ensure compatibility.

Conclusion

A precision machining supplier plays a vital role in delivering high-quality, reliable components for industries with demanding requirements. By leveraging advanced CNC technology, versatile material options, and robust quality assurance, these suppliers meet the needs of aerospace, medical, automotive, and other sectors. Choosing the right supplier involves evaluating equipment, certifications, and experience to ensure consistent results. With the right partner, businesses can achieve cost efficiency, scalability, and precision in their manufacturing processes.