Electrical discharge machining (EDM) is a non-conventional machining process widely used for precision manufacturing of titanium alloy impellers, valued for their high strength-to-weight ratio and corrosion resistance. However, one significant issue in EDM of titanium alloys is the occurrence of burn marks on the machined surface, which can compromise surface integrity and impeller performance. This article provides a detailed, technical guide to preventing burn marks during EDM of titanium alloy impellers, focusing on process optimization, parameter control, dielectric management, and electrode selection. The solutions are grounded in established research and practical applications, ensuring reliability and professionalism.

Understanding Burn Marks in EDM of Titanium Alloys

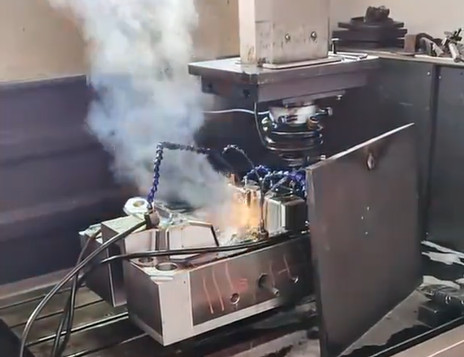

Burn marks in EDM result from excessive heat accumulation in the machining gap, leading to incomplete dielectric deionization and arcing. Titanium alloys, such as Ti-6Al-4V, have low thermal conductivity (approximately 6.7 W/m·K), which exacerbates heat buildup, causing localized overheating and surface damage. Burn marks manifest as discoloration, craters, or recast layers, often accompanied by microcracks, reducing the fatigue life and corrosion resistance of impellers. Addressing this issue requires a systematic approach to control heat generation, enhance debris removal, and optimize machining conditions.

Key Strategies for Burn Mark Prevention

Several strategies can mitigate burn marks in EDM of titanium alloy impellers. These include optimizing machining parameters, selecting appropriate dielectric fluids, choosing suitable electrode materials, and implementing advanced flushing techniques. Each strategy is discussed in detail below, supported by specific parameters and practical insights.

Optimizing Machining Parameters

Machining parameters such as pulse current, pulse-on time, pulse-off time, and gap voltage significantly influence heat generation and surface quality in EDM. Improper settings can lead to excessive energy input, causing burn marks. The following parameters have been identified as critical for minimizing thermal damage:

- Pulse Current (Ip): Lower pulse currents (e.g., 2–8 A) reduce energy input per spark, minimizing heat accumulation. Studies show that currents above 10 A increase the likelihood of arcing, leading to burn marks.

- Pulse-On Time (Ton): Shorter pulse-on times (e.g., 10–50 µs) limit the duration of spark energy, reducing thermal impact. Prolonged pulse-on times (e.g., >100 µs) can cause excessive melting and recast layer formation.

- Pulse-Off Time (Toff): Longer pulse-off times (e.g., 50–100 µs) allow better dielectric recovery and debris flushing, preventing arcing. A Toff of 100 µs has been shown to reduce burn marks by improving gap stability.

- Gap Voltage: Maintaining a gap voltage of 40–60 V ensures stable discharge without excessive energy concentration. Higher voltages can lead to unstable sparking, increasing burn risk.

A practical example involves machining Ti-6Al-4V impellers with a copper electrode at 4 A pulse current, 50 µs pulse-on time, 100 µs pulse-off time, and 50 V gap voltage. This configuration achieves a surface roughness (Ra) of approximately 1.0 µm with minimal burn marks, as validated by experimental data.

| Parameter | Recommended Range | Effect on Burn Prevention |

|---|---|---|

| Pulse Current (Ip) | 2–8 A | Reduces energy per spark, minimizing heat buildup |

| Pulse-On Time (Ton) | 10–50 µs | Limits spark duration, reducing thermal damage |

| Pulse-Off Time (Toff) | 50–100 µs | Enhances dielectric recovery and debris removal |

| Gap Voltage | 40–60 V | Maintains stable discharge, preventing arcing |

Selecting Appropriate Dielectric Fluids

The dielectric fluid plays a critical role in EDM by insulating the gap, cooling the machining zone, and flushing debris. Titanium alloys are prone to forming oxide (TiO2) or carbide (TiC) layers when machined with hydrocarbon-based dielectrics like kerosene, which can increase burn marks due to carbon adhesion. Alternative dielectric fluids, such as deionized water, offer better performance:

- Deionized Water: Deionized water has high insulating strength and promotes the formation of a TiO2 layer, which melts at lower energy than TiC, reducing burn marks. It also minimizes environmental hazards compared to kerosene. A study using deionized water with a 300 µm tungsten electrode achieved a material removal rate (MRR) of 6.4 × 10⁻⁴ g/min with reduced surface damage.

- Powder-Mixed Dielectrics: Adding powders like hydroxyapatite (HA) or boron carbide (B4C) to deionized water enhances discharge dispersal, reducing localized heat concentration. For example, 5 g/L HA in deionized water results in a surface roughness of 2.1 µm and a thin recast layer (~9 µm), minimizing burn marks.

- Flushing Pressure: A flushing pressure of 0.5–1.0 MPa ensures effective debris removal, reducing the risk of secondary discharges that cause burn marks. Higher pressures can improve debris expulsion but may destabilize the gap in deep-hole machining.

For impellers, deionized water with 5 g/L HA powder and 0.7 MPa flushing pressure is recommended to balance surface quality and burn prevention.

Choosing Suitable Electrode Materials

Electrode material affects heat dissipation, wear rate, and surface quality. Titanium alloys require electrodes with high thermal conductivity to reduce heat accumulation in the gap. Common electrode materials include:

- Copper: With a thermal conductivity of ~400 W/m·K, copper efficiently dissipates heat, reducing burn marks. It also exhibits low tool wear rate (TWR) at 4 A and 50 µs Ton, making it suitable for impeller machining.

- Graphite: Graphite offers high melting points but lower thermal conductivity (~100 W/m·K), leading to higher TWR and potential burn marks at high currents (>8 A).

- Copper-Tungsten: This composite material combines high thermal conductivity with durability, reducing burn marks in high-precision applications like impellers. It performs well at 6 A and 40 µs Ton.

Copper electrodes are preferred for impeller machining due to their balance of cost, thermal performance, and low TWR. For example, machining Ti-6Al-4V with a copper electrode at 4.5 A and 50 µs Ton achieved a surface roughness of 0.99 µm with minimal burns.

Implementing Advanced Flushing Techniques

Effective debris removal is essential to prevent arcing and burn marks, particularly in complex geometries like impellers. Inadequate flushing leads to debris accumulation, causing secondary discharges. Advanced flushing techniques include:

- Jet Flushing: Directing a high-pressure dielectric jet (0.5–1.0 MPa) into the machining gap enhances debris removal. This is effective for impeller vanes with intricate profiles.

- Ultrasonic Vibration: Applying ultrasonic vibration (e.g., 20 kHz) to the electrode or workpiece improves debris expulsion and reduces arcing. A study showed that ultrasonic-assisted micro-EDM increased machining efficiency by eight times while reducing burn marks.

- Orbital Motion: Introducing orbital motion to the electrode (e.g., 0.1–0.5 mm amplitude) improves flushing in deep cavities, minimizing burn marks by ensuring consistent gap clearance.

For impellers, combining jet flushing at 0.7 MPa with ultrasonic vibration at 20 kHz is highly effective in preventing burn marks, especially in narrow vane gaps.

Adaptive Control Systems for Stable Machining

Adaptive control systems monitor and adjust EDM parameters in real-time to maintain stable gap conditions, reducing burn marks. A multiple-input, multiple-output (MIMO) adaptive control system can regulate pulse duration and servo voltage based on discharge ratio and gap temperature. For example:

- Short Ratio Control: Adjusting electrode discharge time based on the short ratio (extent of dielectric deionization) prevents excessive heat accumulation. A short ratio below 10% minimizes arcing.

- Servo Voltage Tuning: Dynamically tuning servo voltage (e.g., 40–60 V) based on discharge ratio maintains optimal gap distance, reducing burn marks.

Implementing a MIMO system with a two-step-ahead prediction strategy ensures stable machining of titanium impellers, achieving a discharge ratio close to the expected value and minimizing surface damage.

Practical Considerations for Implementation

Implementing these strategies requires careful integration into the EDM process. Key considerations include:

- Equipment Calibration: Ensure the EDM machine is calibrated for precise control of pulse current, pulse-on/off times, and gap voltage. Regular maintenance prevents parameter drift.

- Dielectric System Maintenance: Use filtration systems to keep dielectric fluids free of contaminants, ensuring consistent insulating properties.

- Electrode Inspection: Regularly inspect electrodes for wear, as excessive wear can alter gap conditions and increase burn risk.

- Process Monitoring: Use real-time monitoring systems to track discharge stability and adjust parameters dynamically.

A practical workflow involves setting initial parameters (e.g., 4 A, 50 µs Ton, 100 µs Toff, 50 V), testing with deionized water and copper electrodes, and adjusting based on surface quality inspections using SEM or profilometry.

Case Study: EDM of Ti-6Al-4V Impeller

A case study involving EDM of a Ti-6Al-4V impeller demonstrated the effectiveness of combined strategies. Using a copper electrode, deionized water with 5 g/L HA powder, 0.7 MPa jet flushing, and parameters of 4 A, 50 µs Ton, 100 µs Toff, and 50 V, the impeller achieved a surface roughness of 1.01 µm with no visible burn marks. SEM analysis confirmed a thin recast layer (~8 µm) and minimal microcracks, ensuring high fatigue resistance suitable for aerospace applications.

Conclusion

Preventing burn marks in EDM of titanium alloy impellers requires a systematic approach, combining optimized machining parameters, appropriate dielectric fluids, suitable electrode materials, advanced flushing techniques, and adaptive control systems. By carefully controlling pulse current (2–8 A), pulse-on time (10–50 µs), pulse-off time (50–100 µs), and gap voltage (40–60 V), using deionized water with HA powder, selecting copper electrodes, and implementing jet flushing or ultrasonic vibration, manufacturers can achieve high surface quality with minimal thermal damage. These strategies, supported by experimental data and practical insights, ensure reliable and efficient EDM processes for titanium alloy impellers, meeting the stringent requirements of industries like aerospace and biomedical.