Rapid Prototyping with Kesu

Speed up product development with real-time quotes, design for manufacturability (DFM) insights, and a full range of services including CNC machining, mold tooling, 3D printing, and more.

From initial prototype to final production, our platform offers the speed, adaptability, and dependability engineers rely on to bring their ideas to life — faster.

KeSu prototyping quickly converts early-stage design concepts into physical models, offering a fast and cost-effective way to see ideas in reality. This approach is particularly effective through technologies such as 3D printing, CNC machining, and more, with the ability to deliver prototypes typically within 1-3 business days.

Prototyping Processes

Looking for a professional prototyping service to bring your ideas to life and speed up product development? Kesu offers high-quality, fast, and cost-effective rapid prototyping solutions worldwide. Equipped with cutting-edge technology, industrial-grade equipment, and an expert engineering team, we can turn your concept into a functional prototype in just days. Once your prototype is ready, our low-volume manufacturing services ensure a smooth transition to production. Here are our key rapid prototyping processes:

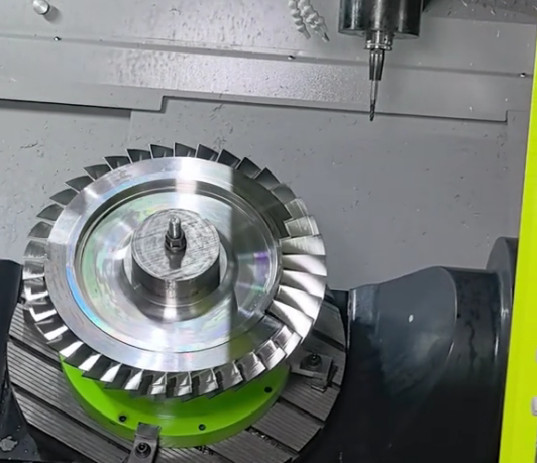

Rapid CNC machining

CNC machining is a highly precise rapid prototyping method. While it focuses on quick turnarounds over extreme tolerances, it still ensures excellent quality. Ideal for low volumes, CNC parts closely match production standards. Though pricier than 3D printing, strength and surface finish are better.

Rapid 3D printing

Our 3D printing services deliver rapid, high-quality prototypes in plastics and metals with various materials and finishes. No tooling is needed, saving time and cost, especially for low volumes. From concept models to functional prototypes, technologies like SLM also support small-scale production needs.

Rapid Die Casting

Rapid Tooling

Prototyping tooling for molding suits orders of 100–2,000 injection molded parts, while larger volumes favor production steel tooling. Rapid tooling offers fast turnaround, lower costs than mass production molds, and delivers parts close to production quality — ideal for functional testing despite higher costs than 3D printing.

sheet metal prototyping

Rapid sheet metal prototyping includes forming, cutting, and assembly processes for producing flat parts like brackets and enclosures, including large components. Although setup times may be longer, it’s cost-effective for large, simple parts. Additionally, CNC machining can add features to the sheet metal parts.

Rapid metal casting

Rapid metal casting, enabled by 3D printing for low-cost patterns, offers an affordable solution for metal part prototyping. Through strong partnerships with major casting companies, we provide near-production quality parts, large sizes, fast speeds, excellent tensile strength, and post-machining options.

One Stop for All Your Prototyping Needs

Kesu provides end-to-end custom manufacturing solutions through a unified platform, helping you save time and speed up production.

Why Choose Us

1

High Quality Parts

Kesu guarantees exceptional prototype quality by employing high-grade materials and precise craftsmanship, all while strictly complying with industry standards.

2

Fast Lead Time

Our streamlined processes ensure rapid prototype delivery, greatly reducing development cycles and accelerating time to market.

3

Engineering Support

Kesu offers comprehensive engineering support, helping optimize designs and overcome technical challenges to enhance prototype development.

We've helped thousands of customers succeed

Thomas

Sales Manager

Addison.H

Head of Designer

Nancy. K

Engineer

He is my long term supplier with all my trust.

Can we please proceed the order for parts as quoted? Drawings and quote attached.

Rapid Prototyping in Multiple Materials

When outsourcing your rapid prototypes, it's essential to choose a dependable rapid prototyping company capable of working with a variety of materials, ensuring the entire project stays under one roof. Kesu is an excellent choice for this, offering prototype fabrication in plastics, metals, and ceramics.

| Name | Description |

| Aluminum | Aluminum and Aluminum Alloy are lightweight and highly versatile material with a high strength-to-weight ratio, excellent corrosion resistance, malleability, and good thermal and electrical conductivity. Ideal for Aluminum CNC machining applications where weight reduction, durability, and efficient heat transfer are important. |

| Brass | 360 Brass (free-machining brass) is a versatile material with excellent machinability, high corrosion resistance, and good electrical conductivity. Commonly used for gears, lock components, pipe fittings, and decorative Brass CNC parts, ideal for electrical components and marine applications. |

| Bronze | 932 Bearing Bronze provides excellent wear and corrosion resistance due to its tin, iron, and zinc content. Commonly used in bearings, bushings, thrust washers, valve components, and Bronze CNC parts subjected to heavy loads or harsh environments, offering high strength and low friction. |

| Cast Iron | Cast Iron is known for its durability and wear resistance, making it an excellent choice for absorbing vibrations. Commonly used in gears, bases, pulleys, and bushings in heavy-duty machinery and equipment, preferred for its ability to withstand high stress and pressure. |

| Copper | Copper 101 and 110 have unmatched thermal and electrical conductivity, making them popular for bus bars, wire connectors, and electrical applications like power transmission systems. CNC machined Copper Alloy Offers durability, corrosion resistance, and ease of fabrication. |

| Invar | Invar is a Ni-Fe alloy with high dimensional accuracy and excellent thermal dimensional stability. Used in aerospace, electronics, and precision engineering for precision instruments, clock pendulums, bi-metallic strips, satellite structures, antennas, and optical systems. |

| Kovar | Kovar is a Ni-Fe-Co alloy known for its excellent thermal expansion properties and dimensional stability, used in electronics, telecommunications, and aerospace for hermetic seals in vacuum tubes, transistors, and turbine blades, enabling airtight sealing with glass. |

| Magnesium | Magnesium and Magnesium Alloy has an excellent strength-to-weight ratio, widely used in automotive, aerospace, and electronics for lightweight components like aircraft structures, engine blocks, transmission cases, and wheels, Magnesium CNC machining improving fuel efficiency and reducing emissions. |

| Stainless Steel | Stainless Steel is a versatile material with exceptional strength, durability, high temperature, and corrosion resistance. Used in construction, automotive, aerospace, and Stainless Steel CNC manufacturing for heat exchangers, exhaust systems, engine components, fasteners, and medical equipment. |

| Steel | Steel (alloy and carbon) provides excellent strength and durability, used for fixtures, mounting plates, draft shafts, axles, torsion bars, gears, bolts, studs, shafts, and structural components in demanding industrial applications. |

| Titanium | Titanium and Titanium Alloy are lightweight, strong, biocompatible, and highly resistant to corrosion, with a high strength-to-weight ratio and excellent temperature resistance. CNC machined Titanium used in aerospace and medical devices for engine components, landing gear, medical implants, turbine blades, and marine applications. |

| Tool Steel | A2 Tool Steel has excellent wear resistance and toughness, commonly used to make fixtures, tools, tool holders, gauges, and punches. |

| Zinc | Zinc and Zinc Alloy are versatile metal with excellent heat resistance, durability, strength, electrical and thermal conductivity, machinability, and corrosion resistance. CNC Zinc is used in automotive parts like gears, bushings, bearings, door and window hardware, electrical connectors, and applications in harsh environments. |

| Name | Description |

| ABS | ABS (Acrylonitrile Butadiene Styrene) is an affordable thermoplastic that has become popular for pre-injection molding prototypes. It is a versatile material known for its strength, durability, and resistance to impact and heat. CNC machined ABS is widely used in automotive and consumer electronics industries. |

| Acrylic | Acrylic is a durable plastic material that is resistant to scratches, making it an ideal choice for various applications such as tanks, panels, and optical displays. It is also lightweight and shatter-resistant, a popular alternative to glass, known for its clarity and transparency. |

| Delrin | Delrin is a plastic with low friction and high stiffness, offering exceptional dimensional accuracy, high toughness, and resistance to impact and wear. Commonly used in automotive, aerospace, and consumer goods for applications requiring precision. |

| Garolite G-10 | Garolite G-10 is a high-pressure laminate of woven fiberglass cloth impregnated with epoxy resin, exhibiting excellent electrical insulation, water resistance, high mechanical strength, and dimensional stability. Used in insulating components, circuit boards, and electrical parts. |

| HDPE | High-density polyethylene (HDPE) is a versatile thermoplastic known for its durability, chemical resistance, impact resistance, structural integrity, and low moisture absorption. Commonly used in packaging, construction, automotive manufacturing, plugs, seals, and as an electrical insulator. |

| Nylon | Nylon is a thermoplastic with high strength, wear resistance, excellent sound/vibration dampening, and low friction coefficient. CNC machined Nylon is commonly used in engineering for gears, bearings, bushings, medical devices, and electronics insulation, notably screws and spacers for circuit boards. |

| PEEK | PEEK (polyether ether ketone) is a thermoplastic with high strength, stiffness, toughness, chemical, biocompatibility, and thermal resistance, suitable for harsh environments. CNC machined PEEK is used in aerospace, automotive, and electronics for aircraft structures, electronic components, and medical implants. |

| Polycarbonate | Polycarbonate is a durable and transparent thermoplastic with good electrical insulation, heat resistance, impact resistance, clarity, flame retardancy, and scratch resistance. CNC machined Polycarbonate is commonly used in safety glasses, protective shields, electrical enclosures, connectors, and insulators. |

| Polypropylene | Polypropylene (PP) is a thermoplastic with a high melting point, high strength-to-weight ratio, excellent chemical resistance, durability, moisture resistance, and fatigue strength. Used in laboratory equipment, medical devices, food processing, automotive, and aircraft components. |

| PPS | Polyphenylene Sulfide (PPS) is a thermoplastic with exceptional chemical resistance, thermal stability, high-temperature resistance, dimensional stability, and electrical insulation. Used in automotive components, electrical connectors, and industrial equipment like fuel systems and bearings. |

| PTFE | PTFE has low friction nonstick properties, excellent chemical resistance, high temperature resistance, and electrical insulating properties. Commonly used in low-friction applications like bearings, seals, gaskets, and parts requiring insulation. |

| PVC | PVC (Polyvinyl chloride) is a plastic with high durability, excellent chemical, UV, and corrosion resistance. CNC machined PVCis used in pipes, fittings, electrical enclosures, tubing, automotive interiors, and commercial building components, offering cost-effectiveness and a long lifespan. |

| Torlon | Torlon is a thermoplastic with exceptional mechanical strength, heat resistance, and chemical resistance, reliable in extreme conditions. Used in aerospace, automotive, and oil and gas, suitable for harsh environments with exposure to chemicals and solvents. |

| UHMW | Ultra-High-Molecular-Weight Polyethylene (UHMW) has high abrasion resistance, durability, excellent wear resistance, low friction coefficient, and impact strength. Used in gears, bearings, liners, conveyors, food processing, agriculture, and automotive components, with shock absorption capabilities. |

| Ultem | ULTEM is a thermoplastic with exceptional strength, stiffness, durability, environmental resistance, heat resistance, low flammability, and electrical insulation. Used in electronic components, surgical instruments, aerospace engine components, medical devices, and corrosive environments. |

| Name | Applicable Materials | Colors | Can Be Applied with |

| Chem Film | Aluminum Alloy | Clear, gold | Media Blasting, Tumbling, Type II Anodizing*, Type III Anodizing with PTFE* |

| Anodizing | Aluminum | Clear, black, grey, red, blue, gold | Media Blasting, Tumbling, Chem film* |

| Black Oxide | Steel, Stainless Steel | Black | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | — | — |

| Hand Polishing | Acrylic | — | Enhanced Cosmetic Appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post CNC processes, except Electropolish and Powder Coat |

| Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | — | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

| Powder Coating Services | Aluminum, Steel, Stainless Steel | Full Pantone or RAL color catalog | — |

| Tumbling | Aluminum Alloy, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post CNC processes, except Electropolish and Powder Coat |

| Vapor Polishing | CNC Polycarbonate (Clear, Black) | — | Enhanced Cosmetic Appearance, Near Optically Clear Applications |

| Zinc Plating | Steel, Stainless Steel | Clear (light blue coating), Black (glossy black coating) | Media Blasting, Tumbling, Passivation |

Rapid Prototyping FAQs

What is rapid prototyping?

What are the main methods of rapid prototyping?

- 3D Printing/Additive Manufacturing: Builds parts layer by layer (e.g., SLA, FDM, SLS).

- CNC Machining: Subtracts material from a solid block to create precise parts.

- Injection Molding: Creates prototypes using molds for high-fidelity parts.

- Vacuum Casting: Uses silicone molds to produce small batches of parts.

- Digital Prototyping: Virtual models or simulations (e.g., software mockups or CAD simulations).

What are the benefits of rapid prototyping?

- Speeds up the design process by allowing quick iterations.

- Reduces costs by identifying flaws early.

- Enables testing of form, fit, and function.

- Facilitates collaboration and feedback from stakeholders.

- Supports customization and complex geometries.

What industries use rapid prototyping?

- Automotive (e.g., part testing, design validation).

- Aerospace (e.g., lightweight components).

- Medical (e.g., custom implants, surgical guides).

- Consumer products (e.g., electronics, wearables).

- Architecture and industrial design.

What materials can be used in rapid prototyping?

- 3D Printing: Plastics (ABS, PLA), resins, metals, composites.

- CNC Machining: Metals (aluminum, steel), plastics, wood.

- Injection Molding: Thermoplastics, elastomers.

- Vacuum Casting: Polyurethanes, silicones.