Stereolithography (SLA) 3D printing is a leading additive manufacturing technology known for its precision, smooth surface finish, and versatility in producing complex geometries. This guide provides a detailed, technical overview of SLA 3D printing, covering its principles, processes, materials, applications, and technical specifications. Designed for professionals and enthusiasts, this resource aims to deliver a systematic understanding of SLA technology and its practical implementation.

What Is SLA 3D Printing?

SLA 3D printing, or stereolithography, is an additive manufacturing process that uses a laser to cure liquid resin into solid parts layer by layer. Invented in the 1980s by Chuck Hull, SLA is one of the earliest 3D printing technologies and remains a cornerstone in industries requiring high accuracy and fine detail. The process involves a UV laser selectively curing photopolymer resin in a vat, creating precise, durable parts with exceptional surface quality.

The core principle of SLA relies on photopolymerization, where UV light triggers a chemical reaction in the resin, hardening it into a solid form. This process allows for intricate designs that are difficult to achieve with traditional manufacturing methods. SLA printers are widely used in prototyping, dental, jewelry, and medical applications due to their ability to produce high-resolution parts.

How Does SLA 3D Printing Work?

The SLA printing process involves several key steps, each critical to achieving high-quality results. Below is a systematic breakdown of the workflow:

- Design Creation: A 3D model is designed using CAD software and exported as an STL or OBJ file.

- Slicing: The model is sliced into thin layers using slicer software, generating instructions for the printer.

- Resin Preparation: Liquid photopolymer resin is loaded into the printer’s vat, ensuring proper viscosity and temperature.

- Laser Curing: A UV laser scans the resin surface, curing it point by point to form each layer.

- Layer Building: The build platform moves incrementally (typically 25-100 microns per layer) to create the part layer by layer.

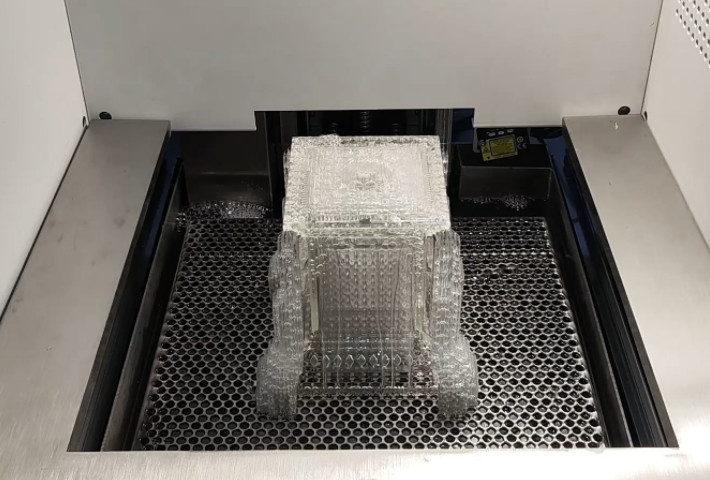

- Post-Processing: The printed part is removed, cleaned in a solvent (e.g., isopropyl alcohol), and cured under UV light to achieve final strength.

Key parameters affecting print quality include laser power (typically 100-500 mW), layer thickness (25-100 µm), and resin type. The precision of the laser and the quality of the optics system determine the resolution, often achieving tolerances as low as ±0.01 mm.

Materials Used in SLA 3D Printing

SLA 3D printing uses photopolymer resins, which are available in various formulations to meet specific application needs. These materials differ in mechanical properties, color, transparency, and curing requirements. Common resin types include:

| Resin Type | Properties | Applications |

|---|---|---|

| Standard Resin | High detail, smooth finish, moderate strength | Prototyping, concept models, visual aids |

| Tough Resin | High impact resistance, durability | Functional prototypes, mechanical parts |

| Flexible Resin | Elastic, soft-touch properties | Gaskets, wearable devices, soft robotics |

| Castable Resin | Burns out cleanly for casting | Jewelry, dental restorations, investment casting |

| High-Temperature Resin | Heat resistance up to 200°C | Molds, aerospace components, thermal testing |

Resin selection depends on the application, with considerations for tensile strength (20-80 MPa), elongation at break (5-50%), and thermal stability. Specialized resins, such as biocompatible options for dental or medical use, must meet regulatory standards like ISO 10993.

Applications of SLA 3D Printing

SLA 3D printing is employed across various industries due to its precision and material versatility. Below are key applications:

- Prototyping: SLA produces high-fidelity prototypes for design validation, with smooth surfaces reducing the need for post-processing.

- Dental: Used for dental models, aligners, and surgical guides, leveraging biocompatible resins for patient safety.

- Jewelry: Castable resins enable intricate designs for lost-wax casting, producing detailed jewelry pieces.

- Medical: SLA creates anatomical models, hearing aids, and custom implants with high accuracy.

- Engineering: Functional parts like gears, housings, and enclosures benefit from tough and high-temperature resins.

Each application leverages SLA’s ability to produce parts with fine details (down to 25 µm) and complex geometries, making it ideal for small-batch production and custom components.

Technical Specifications of SLA 3D Printers

SLA printers vary in build volume, resolution, and speed, tailored to specific use cases. Below is a comparison of common SLA printer specifications:

| Parameter | Typical Range | Impact |

|---|---|---|

| Build Volume | 50 x 50 x 50 mm to 300 x 300 x 600 mm | Determines maximum part size |

| Laser Power | 100-500 mW | Affects curing speed and precision |

| Layer Thickness | 25-100 µm | Influences resolution and print time |

| XY Resolution | 25-100 µm | Controls detail accuracy in the XY plane |

| Print Speed | 10-50 mm/hour (Z-axis) | Balances speed and quality |

High-end SLA printers, such as those from Formlabs or 3D Systems, offer larger build volumes and finer resolutions, while desktop models prioritize affordability and ease of use for smaller projects.

Advantages of SLA 3D Printing

SLA offers distinct advantages that make it a preferred choice for precision-driven applications:

- High Precision: Achieves tolerances of ±0.01 mm, ideal for intricate designs.

- Smooth Surface Finish: Produces parts with minimal layer lines, reducing post-processing.

- Material Versatility: Supports a wide range of resins for diverse applications.

- Complex Geometries: Enables overhangs and internal structures without extensive supports.

These benefits make SLA suitable for industries where accuracy and aesthetics are critical, such as dental, jewelry, and medical device manufacturing.

Limitations of SLA 3D Printing

While SLA excels in precision, it has constraints that users must consider:

- Material Cost: Resins are expensive, ranging from $50-200 per liter, depending on type.

- Post-Processing: Parts require cleaning and curing, adding time and equipment costs.

- Limited Build Volume: Large parts may require industrial SLA systems, which are costly.

- Resin Handling: Resins can be toxic, requiring ventilation and protective equipment.

These limitations may impact scalability for high-volume production, making SLA more suited for low-volume, high-precision applications.

Optimizing SLA 3D Printing for Professional Use

To maximize SLA performance, professionals should focus on the following:

- Printer Calibration: Regularly calibrate laser alignment and platform leveling to ensure accuracy.

- Resin Management: Store resins at recommended temperatures (15-25°C) and filter after use to remove debris.

- Support Structures: Optimize support placement to minimize material use and simplify removal.

- Post-Processing: Use automated washing and curing stations to streamline workflows and ensure consistent results.

Software tools like PreForm (Formlabs) or 3D Sprint (3D Systems) can enhance print preparation by optimizing orientation, supports, and layer settings.

FAQ

What is the accuracy of SLA 3D printing?

SLA 3D printing achieves tolerances of ±0.01 mm, with XY resolution as fine as 25 µm, depending on the printer and resin used.

How long does SLA printing take?

Print time varies by part size and layer thickness, typically ranging from 10-50 mm/hour along the Z-axis. A small part (50 mm tall) may take 1-5 hours.

Are SLA resins safe to handle?

Most SLA resins are toxic and require gloves, ventilation, and proper storage. Biocompatible resins are safer for medical applications but still need careful handling.

Can SLA print large parts?

SLA printers have limited build volumes (up to 300 x 300 x 600 mm for industrial models). Large parts may require segmentation or industrial systems.