Sleeves are critical components in various industries, serving as protective or functional elements in machinery, clothing, electronics, and more. This article explores sleeve types, materials, manufacturing processes, applications, and maintenance, providing a comprehensive guide for professionals and enthusiasts. The focus is on technical details, specifications, and practical considerations to ensure clarity and utility.

Definition and Purpose of Sleeves

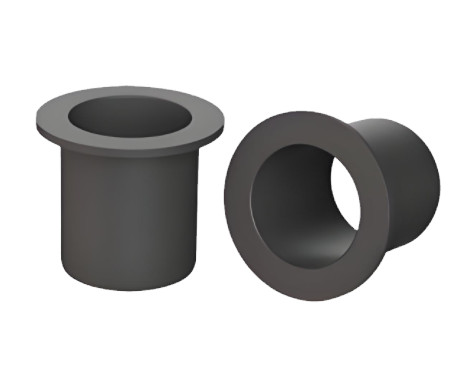

A sleeve is a cylindrical or tubular component designed to encase, protect, or enhance the functionality of another object. Sleeves are used to reduce wear, provide insulation, ensure structural integrity, or improve aesthetics. They are found in mechanical systems (e.g., bearing sleeves), electronics (e.g., cable sleeves), and textiles (e.g., garment sleeves). The purpose varies by application, but sleeves generally extend the lifespan or efficiency of the encased component.

Types of Sleeves

Sleeves are categorized based on their material, structure, or application. Below is a detailed breakdown of common sleeve types.

| Type | Description | Applications | Key Specifications |

|---|---|---|---|

| Protective Sleeves | Tubular covers shielding components from environmental damage, abrasion, or heat. | Cables, hoses, pipes. | Material: PVC, silicone, nylon; Temperature resistance: -40°C to 200°C. |

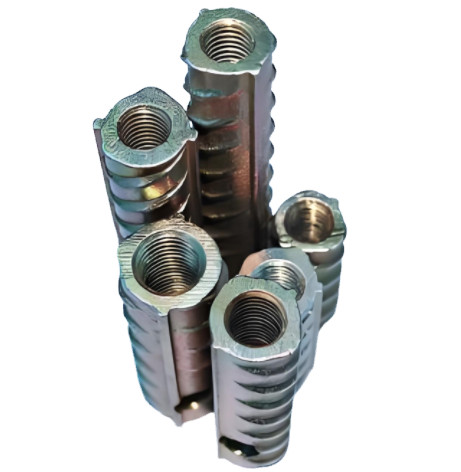

| Bearing Sleeves | Cylindrical components reducing friction in rotating machinery. | Motors, pumps, automotive systems. | Inner diameter: 10-500 mm; Material: Steel, bronze; Hardness: 50-60 HRC. |

| Thermal Sleeves | Insulating sleeves for heat retention or dissipation. | Engines, HVAC systems. | Thermal conductivity: 0.1-0.5 W/m·K; Thickness: 2-10 mm. |

| Textile Sleeves | Fabric-based sleeves for clothing or flexible covers. | Garments, flexible ducts. | Material: Cotton, polyester; Stretch: 5-20% elongation. |

Materials Used in Sleeve Manufacturing

The choice of material for sleeves depends on the application, environmental conditions, and performance requirements. Below are the primary materials and their properties.

- Metals (Steel, Aluminum, Bronze): Used in bearing sleeves for high durability and load-bearing capacity. Steel sleeves, for example, have a tensile strength of 400-1000 MPa and are resistant to deformation under heavy loads.

- Polymers (PVC, Silicone, Nylon): Common in protective and thermal sleeves due to flexibility and chemical resistance. Silicone sleeves withstand temperatures from -50°C to 250°C.

- Composites (Fiberglass, Carbon Fiber): Used in high-performance applications requiring lightweight and high strength. Fiberglass sleeves offer a tensile strength of 300-500 MPa.

- Textiles (Cotton, Polyester): Employed in garment sleeves or flexible covers, offering breathability and stretch. Polyester sleeves have a tear strength of 20-50 N.

Material selection considers factors like corrosion resistance, thermal stability, and mechanical strength. For instance, in marine environments, stainless steel sleeves with a corrosion resistance of <0.1 mm/year are preferred.

Manufacturing Processes for Sleeves

Sleeve production involves precise techniques to meet dimensional and performance standards. Key processes include:

- Extrusion: Used for polymer and metal sleeves, creating continuous tubular shapes. Extruded PVC sleeves achieve tolerances of ±0.1 mm.

- Machining: Employed for metal bearing sleeves, ensuring precise inner and outer diameters. CNC machining achieves surface finishes of Ra 0.8 µm.

- Molding: Common for silicone and composite sleeves, allowing complex shapes. Injection molding ensures uniformity with a dimensional accuracy of ±0.05 mm.

- Weaving or Knitting: Used for textile sleeves, providing flexibility and breathability. Knitted polyester sleeves achieve a density of 200-400 g/m².

Quality control during manufacturing includes hardness testing (e.g., Rockwell C scale for metal sleeves), dimensional checks, and environmental testing (e.g., ASTM D4060 for abrasion resistance).

Applications of Sleeves

Sleeves serve diverse functions across industries. Below are key applications with technical details.

- Mechanical Systems: Bearing sleeves in motors reduce friction, supporting shaft speeds up to 10,000 RPM. They require a clearance fit of 0.01-0.05 mm for optimal performance.

- Electronics: Cable sleeves protect wiring from abrasion and electromagnetic interference. Braided nylon sleeves offer a dielectric strength of 4 kV/mm.

- Automotive: Thermal sleeves in exhaust systems maintain temperatures below 300°C, extending component life by 20-30%.

- Textiles: Garment sleeves provide fit and comfort, with stretch fabrics allowing 10-15% elongation for ease of movement.

Design Considerations for Sleeves

Designing sleeves requires balancing functionality, durability, and cost. Key considerations include:

- Dimensional Accuracy: Sleeves must match the encased component’s dimensions. For example, bearing sleeves require a tolerance of ±0.02 mm for inner diameter.

- Environmental Resistance: Sleeves in harsh environments (e.g., chemical plants) need materials with high corrosion resistance, such as PTFE with a pH resistance range of 0-14.

- Load Capacity: Metal sleeves in heavy machinery must withstand loads up to 50 kN without deformation.

- Thermal Properties: Thermal sleeves must maintain insulation or dissipation, with materials like ceramic fibers offering thermal conductivity as low as 0.08 W/m·K.

Maintenance and Inspection of Sleeves

Proper maintenance ensures sleeve longevity and performance. Recommended practices include:

- Regular Inspection: Check for wear, cracks, or deformation. For bearing sleeves, use ultrasonic testing to detect internal flaws.

- Cleaning: Remove contaminants using non-abrasive cleaners. For textile sleeves, machine washing at 30°C preserves fabric integrity.

- Lubrication: Apply lubricants (e.g., molybdenum disulfide) to metal sleeves to reduce friction, extending life by up to 25%.

- Replacement Scheduling: Replace sleeves based on usage cycles. For example, protective cable sleeves in industrial settings are replaced every 12-18 months.

Inspection frequency depends on the application. High-load bearing sleeves require monthly checks, while textile sleeves may need annual inspections.

Sleeve Specifications by Industry

Different industries demand specific sleeve properties. The table below outlines typical requirements.

| Industry | Sleeve Type | Key Specifications | Maintenance Interval |

|---|---|---|---|

| Automotive | Thermal Sleeves | Heat resistance: 200-500°C; Thickness: 3-8 mm | 6-12 months |

| Electronics | Protective Sleeves | Dielectric strength: 3-5 kV/mm; Flexibility: 180° bend radius | 12-24 months |

| Manufacturing | Bearing Sleeves | Hardness: 55-65 HRC; Tolerance: ±0.01 mm | 3-6 months |

| Textiles | Fabric Sleeves | Stretch: 10-20%; Tear strength: 30-50 N | 12 months |

Conclusion

Sleeves are versatile components critical to multiple industries, from protecting cables to reducing friction in machinery. Understanding their types, materials, manufacturing processes, and maintenance requirements ensures optimal performance and longevity. By selecting the right sleeve for specific applications and adhering to proper maintenance protocols, professionals can enhance system efficiency and reliability.

Frequently Asked Questions about Sleeves

What is a sleeve?

A sleeve is a tubular component designed to fit over or inside another part, providing protection, support, insulation, or precise alignment.

What’s the difference between a sleeve and a bushing?

While both are tubular components:

Sleeves often provide general protection or alignment.

Bushings are specifically designed to reduce friction or act as bearings.

Are sleeves reusable?

It depends on the type and condition. Some sleeves (e.g., metal or rigid plastic) can be reused if undamaged, while others (e.g., heat-shrink or single-use seals) are designed for one-time use.