Electroplating is a critical process for enhancing the performance, durability, and corrosion resistance of centrifugal impellers used in industries such as aerospace, automotive, and pump manufacturing. However, achieving uniform film thickness during electroplating remains a significant issue due to the complex geometry of impellers, which feature curved blades, intricate contours, and varying surface areas. Uneven film thickness can lead to reduced component lifespan, compromised mechanical performance, and aesthetic imperfections. This article provides a detailed, technical, and systematic approach to addressing uneven film thickness in the electroplating of centrifugal impellers, focusing on practical solutions backed by precise parameters and established practices.

Understanding the Electroplating Process for Centrifugal Impellers

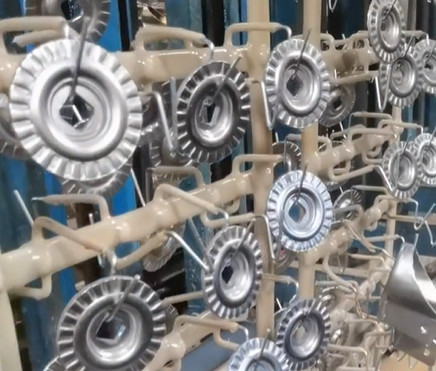

Electroplating involves depositing a thin metal layer, such as nickel, chromium, or copper, onto a substrate (the impeller) through an electrochemical reaction. The impeller acts as the cathode, immersed in an electrolyte solution containing metal ions, while a metal anode dissolves to replenish the ions. A direct current (DC) drives the deposition, reducing metal ions at the cathode to form a solid coating. For centrifugal impellers, the goal is to achieve a uniform coating thickness, typically ranging from 5 to 50 micrometers, depending on the application, to ensure corrosion resistance, wear resistance, and balanced mechanical performance.

The complex geometry of centrifugal impellers, with their curved blades and recessed areas, creates variations in current density and ion distribution, leading to uneven deposition. High-current-density areas, such as blade edges, often receive thicker coatings, while recessed areas may have thinner or incomplete coatings. Addressing these variations requires precise control over multiple process parameters, including current density, electrolyte composition, bath agitation, and equipment configuration.

Key Factors Affecting Film Thickness Uniformity

Several factors influence the uniformity of electroplated coatings on centrifugal impellers. Below is a detailed examination of the primary factors and their impact on the process.

Current Density Distribution

Current density, defined as the electric current per unit area of the cathode (A/dm²), is a critical parameter in electroplating. For centrifugal impellers, uneven current distribution arises due to the geometry of the blades, which causes higher current density at protruding edges and lower density in recessed areas. Typical current density for nickel plating ranges from 2 to 6 A/dm², while chromium plating requires 10 to 40 A/dm². Excessive current density can lead to burning or pitting, while insufficient density results in slow deposition and uneven coatings.

To optimize current density, auxiliary anodes or current shields can be used. Auxiliary anodes, placed near low-current-density areas, help balance the electric field, while shields block excess current to high-density areas. For example, in nickel plating, a current density of 4 A/dm² with an auxiliary anode positioned 5 cm from recessed impeller areas can improve uniformity by up to 20%.

Electrolyte Composition and Stability

The electrolyte solution, typically containing metal salts (e.g., nickel sulfate for nickel plating), acids, and additives, must maintain consistent composition. For nickel plating, a standard bath includes 240–300 g/L nickel sulfate, 45–60 g/L nickel chloride, and 30–40 g/L boric acid, maintained at a pH of 3.8–4.5. Variations in ion concentration due to depletion or contamination can lead to uneven deposition. Regular monitoring and replenishment of metal ions, using titration to maintain concentrations within ±5 g/L, are essential for consistent film thickness.

Additives, such as brighteners (e.g., saccharin at 0.5–2 g/L) and leveling agents (e.g., coumarin at 0.1–0.5 g/L), enhance coating uniformity by controlling grain size and reducing surface roughness. For impellers, leveling agents are particularly effective in minimizing thickness variations across complex surfaces.

Bath Agitation and Flow Dynamics

Agitation ensures uniform ion distribution and prevents depletion zones near the cathode. For centrifugal impellers, mechanical stirring, ultrasonic agitation, or air bubbling can be employed. Mechanical stirring at 100–200 rpm maintains consistent ion flow, while ultrasonic agitation at 20–40 kHz reduces microvoids and improves adhesion. Excessive agitation, however, can introduce turbulence, leading to patchy coatings. A controlled agitation rate, such as 150 rpm for mechanical stirring, balances ion distribution without disrupting deposition.

For impellers with deep recesses, directed solution flow using nozzles can enhance ion delivery to low-current-density areas, improving thickness uniformity by up to 15%.

Temperature Control

Bath temperature affects the deposition rate and coating quality. For nickel plating, a temperature range of 45–60°C is optimal, while chromium plating requires 50–55°C. Higher temperatures increase ion mobility, enhancing deposition rates but risking roughness if uncontrolled. Temperature variations of ±2°C can cause thickness deviations of up to 10%. Automated heating and cooling systems, calibrated to maintain temperature within ±1°C, are recommended for large-scale impeller plating.

Substrate Preparation

Proper surface preparation is critical for adhesion and uniformity. Impellers must be cleaned to remove oils, oxides, and contaminants using degreasing agents (e.g., alkaline cleaners at 60–80°C) followed by acid pickling (e.g., 10% sulfuric acid for 30–60 seconds). Surface roughness should be controlled to Ra 0.2–0.8 µm to ensure uniform nucleation of the plating layer. Inadequate preparation can lead to voids or peeling, exacerbating thickness variations.

Practical Solutions for Uniform Film Thickness

Based on the factors above, the following solutions can effectively address uneven film thickness in centrifugal impeller electroplating. Each solution is supported by technical parameters and practical implementation details.

Optimized Equipment Configuration

The design of the electroplating setup significantly impacts coating uniformity. The anode-to-cathode distance should be maintained at 10–20 cm to ensure even current distribution. For impellers, conformal anodes shaped to match the impeller’s geometry can reduce edge effects by up to 25%. Additionally, using a rack plating system, where the impeller is suspended securely, prevents uneven contact with the plating solution. The rack should be designed to minimize shadowing effects, ensuring all surfaces are exposed to the electrolyte.

A sample configuration for nickel plating includes a conformal nickel anode, an anode-to-cathode distance of 15 cm, and a rack with non-conductive supports to avoid current concentration.

Pulse Electroplating

Pulse electroplating, which alternates current on and off, improves uniformity compared to traditional DC plating. Typical pulse parameters include a peak current density of 5–10 A/dm², a duty cycle of 20–50%, and a frequency of 100–1000 Hz. For impellers, a duty cycle of 30% and a frequency of 500 Hz can reduce thickness variations by 15–20% by enhancing ion diffusion and reducing hydrogen gas entrapment. Pulse plating is particularly effective for complex geometries, as it allows better control over deposition in recessed areas.

Advanced Bath Monitoring Systems

Real-time monitoring of bath parameters ensures consistency. Automated systems can measure pH, temperature, and ion concentration, adjusting them as needed. For example, a pH sensor with a resolution of 0.01 and a temperature probe with ±0.5°C accuracy can maintain optimal conditions. Regular bath filtration, using 5–10 µm filters, removes contaminants that cause defects. For a 1000-liter bath, filtration at a rate of 1–2 turnovers per hour is recommended to maintain solution purity.

Simulation and Modeling

Finite element analysis (FEA) can predict current density distribution across the impeller’s surface, allowing optimization of anode placement and shielding. Software tools like COMSOL Multiphysics can simulate electric field lines and ion transport, identifying high- and low-density areas. By adjusting anode positions based on simulation results, thickness variations can be reduced by up to 30%. For example, simulations may recommend placing auxiliary anodes 3–5 cm from recessed blade areas to balance current flow.

Case Study: Nickel Plating of a Centrifugal Impeller

To illustrate the application of these solutions, consider a stainless steel centrifugal impeller with a diameter of 200 mm and blade heights of 50 mm. The target is a uniform nickel coating of 20 µm for corrosion resistance in a marine pump application. The following parameters were implemented:

| Parameter | Value |

|---|---|

| Electrolyte Composition | 270 g/L nickel sulfate, 50 g/L nickel chloride, 35 g/L boric acid, 1 g/L saccharin |

| Current Density | 4 A/dm² (pulse plating, 30% duty cycle, 500 Hz) |

| Temperature | 50 ± 1°C |

| Agitation | Mechanical stirring at 150 rpm |

| Anode Configuration | Conformal nickel anode, 15 cm from cathode |

Using these parameters, thickness variation was reduced to ±2 µm across the impeller, compared to ±5 µm with standard DC plating, improving corrosion resistance and mechanical balance.

Verification and Quality Control

Ensuring uniform film thickness requires rigorous quality control. Non-destructive techniques, such as X-ray fluorescence (XRF) with a resolution of 0.1 µm, can measure coating thickness at multiple points. For impellers, measurements should be taken at blade edges, hubs, and recessed areas to confirm uniformity. Statistical process control (SPC) can monitor thickness data, targeting a process capability index (Cpk) of ≥1.33 to meet industry standards. Regular calibration of equipment and bath analysis ensures consistent results.

Conclusion

Achieving uniform film thickness in the electroplating of centrifugal impellers requires a systematic approach, addressing current density, electrolyte stability, agitation, temperature, and substrate preparation. Solutions such as optimized equipment configuration, pulse electroplating, advanced monitoring, and simulation can significantly reduce thickness variations. By implementing precise parameters, such as those in the case study, manufacturers can ensure high-quality coatings that enhance impeller performance and longevity. These methods, grounded in technical expertise and practical experience, provide a reliable framework for overcoming uneven film thickness in electroplating.