Quality Surface Finishing Service

Your one-stop machine shop for manufacturing and surface finishing. Get your metal and plastic parts CNC machined with high quality and aesthetic surface finish. High-quality surface finishing services improve your part’s aesthetics and functions regardless of the manufacturing process used. Deliver quality metal, composites, and plastic finishing services so you can bring the prototype or part you dream of to life.

- Fast turnaround

- Tolerance as tight as ±0.005mm

- Advanced In-house Equipments

- 200+ Experienced staff

What parts use surface finishing techniques

CNC Machined Parts

Rapid Tooling Parts

3D-printed Parts

Die-casted Parts

Sheet Metal Fabrications

Extruded Parts

From Design to Prototyping to Production

- 15+ Years of Experience

- ISO 9001:2015 certified QMS

- CMM Quality Inspections

- One-Stop Service Option

Custom Surface Finishing service

1

Rapid Prototyping

We offer high-quality rapid prototyping services in China, providing you with more competitive surface finishing prices and faster delivery times. We have developed the latest rapid prototyping technology to meet your design challenges, and will work with you to verify and improve your product surface treatment prototyping, conduct functional testing, and carry out engineering verification.

2

Rapid Manufacturing

KeSu is your best surface finishing manufacturing partner in China. We offer a range of solutions from effective rapid prototyping to production of surface finishing parts. Our surface finishing company's rich machining experience and ability to integrate resources enable us to meet the needs of any projects and ensure your parts always meet the highest quality standards.

3

Custom Surface Finishing

We provide one-stop rapid surface finishing services and cost-effective rapid custom surface treatment machining services. Do you need production-grade materials, complex geometric shapes, tight tolerances, or fine details? Working with the KeSu surface finishing factory, you can get surface finishing parts to the specs you require through the design prototyping and manufacturing process.

We've helped thousands of customers succeed

Thomas

Sales Manager

Addison.H

Head of Designer

Nancy. K

Engineer

He is my long term supplier with all my trust.

Can we please proceed the order for parts as quoted? Drawings and quote attached.

Surface Finishing Types

| Name | Description |

|---|---|

| Polishing | Applicable to Aluminium, Stainless Steel, Brass. Achieves a surface roughness of Ra0.8μm-32μm. |

| Grinding | Applicable to Aluminium, Stainless Steel, Brass. Achieves a surface roughness of Ra0.63-0.01μm. |

| Brushing | Applicable to Aluminium, Stainless Steel, Brass. Achieves a surface roughness of Ra1.2μm-Ra47μm. |

| Sandblasting | Applicable to Aluminium, Steel, Stainless Steel, Brass, Bronze, Copper, Titanium, Magnesium, ABS, HDPE, Nylon, PC, POM, PMMA, PTFE. Matte finish, thickness 1-100μm, roughness Ra10μm-60μm. |

| Painting | Applicable to Aluminium, Steel, Stainless Steel, ABS. Available in Black or any RAL code/Pantone number. Thickness 10-100μm. |

| Powder Painting | Applicable to Aluminium, Steel, Stainless Steel, ABS. Available in Black or any RAL code/Pantone number. Thickness 50-150μm. |

| Anodizing | Applicable to Aluminium. Available in black, clear, or any RAL code/Pantone number. Thickness 4-8μm (clear), 8-12μm (color). |

| Hard Anodized | Applicable to Aluminium. Available in Black, Clear. Thickness 25-50μm. |

| Passivation | Applicable to Steel, Stainless Steel, Brass. Thickness 1-10μm. |

| Zinc Plating | Applicable to Steel, Stainless Steel, Brass, Bronze. Available in Clear, Black, Colourful. |

| Nickle Plating | Applicable to Aluminium, Steel, Stainless Steel, Brass, Bronze, Copper. Clear finish, thickness 6-100μm. |

| Chrome Plating | Applicable to Aluminium, Steel, Stainless Steel, Brass, Bronze, Copper. Available in Clear, Black. Thickness 1-3μm (Cosmetic), 50-100μm (Hard). |

| Blacken/Black Oxide | Applicable to Steel, Stainless Steel. Black finish, thickness 0-30μm. |

| Black & Zinc | Applicable to Steel, Stainless Steel, Brass, Bronze. Black finish. |

| Teflon Coating | Applicable to Aluminium, Steel, Stainless Steel. Black finish. |

| Titanium Coating | Applicable to Stainless Steel. Available in Gold, White, Bronze, Silver, Black, Blue, Rose, Purple. Thickness 0.1μm-5μm. |

| DLC Coating | Applicable to Steel. Black finish, thickness 1-4μm. |

| Laser Marking | Applicable to Aluminium, Steel, Stainless Steel, Brass, Bronze, Copper, Titanium, Magnesium, ABS, HDPE, Nylon, PC, POM, PMMA, PTFE. Available in Black, White, Grey, and other colors. |

| Silk Screen | Applicable to Aluminium, Steel, Stainless Steel, Brass, Bronze, Copper, Titanium, Magnesium, ABS, HDPE, Nylon, PC, POM, PMMA, PTFE. Available in Black or any RAL code/Pantone number. |

| Transfer Printing | Applicable to Stainless Steel, Metal with Coating, ABS, PE, PP. Available in any RAL code/Pantone number. |

| Micro Arc Oxidation | Applicable to Aluminium, Magnesium, Titanium. Available in Black, Grey. |

Surface Finishing FAQs

What is surface finishing?

What are common surface finishing techniques?

Why is surface finishing important?

What materials can undergo surface finishing?

How do I choose the right surface finishing method?

Is surface finishing environmentally friendly?

How long does surface finishing take?

Can surface finishes be repaired?

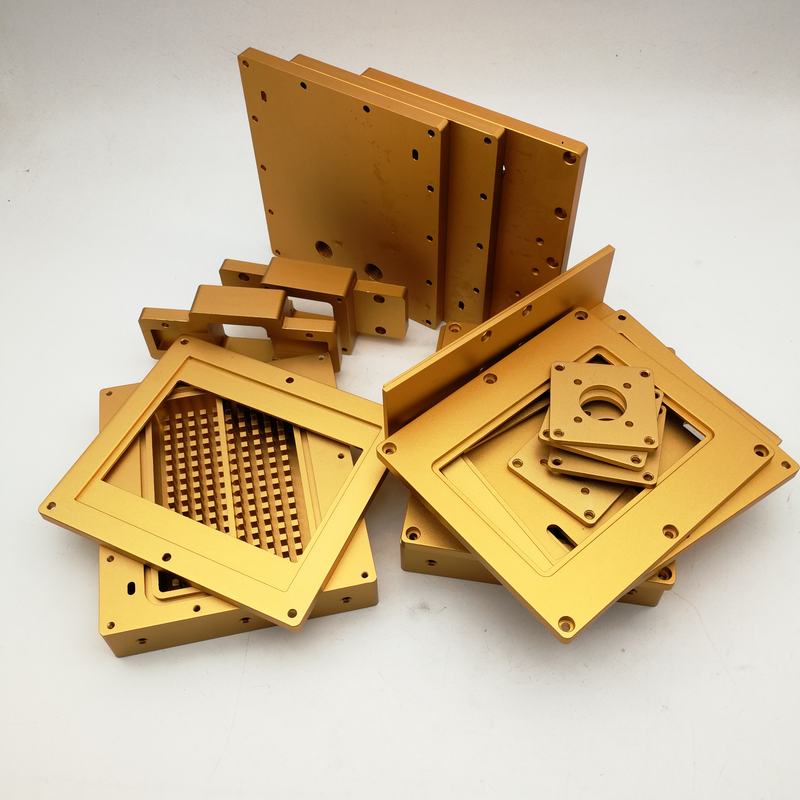

Surface Finishing Parts

Quote Now to Start Your Surface Finishing Project

Complete Surface Finishing services from prototype to production ensure high quality, fast delivery and competitive prices.