Machining high-precision thin-walled titanium alloy parts presents unique challenges due to the material's properties, such as high strength, low thermal conductivity, and susceptibility to deformation. This article explores key considerations for optimizing the machining process, including structural design, clamping techniques, heat treatment, machining strategies, and residual stress management. Each aspect is critical to achieving dimensional accuracy and meeting stringent performance requirements.

Structural Design for Machining Adaptability

The structural design of thin-walled titanium alloy parts significantly impacts machining precision and performance. The design must balance functional requirements with manufacturability to minimize deformation during processing.

- Symmetrical Structures: Designing parts with symmetrical geometries ensures uniform internal stress distribution during machining. This reduces uneven force release, which can cause warping or distortion.

- Uniform Wall Thickness: Maintaining consistent wall thickness across the part prevents stress concentration and uneven deformation. For instance, a wall thickness variation of less than 0.1 mm is often targeted for high-precision parts.

- Rounded Transitions: Incorporating arc-shaped transitions at corners mitigates stress concentration during machining or heat treatment. A fillet radius of 1.5–3 mm is typically recommended to reduce localized stress.

By optimizing the part's geometry, manufacturers can enhance machining stability and achieve tolerances as tight as ±0.01 mm, critical for aerospace and medical applications.

Clamping Techniques for Thin-Walled Parts

Thin-walled titanium alloy parts have low rigidity, making them prone to deformation under clamping forces. Proper clamping strategies are essential to maintain positional accuracy and prevent distortion.

| Clamping Parameter | Recommendation | Impact |

|---|---|---|

| Clamping Position | Symmetrical placement relative to part geometry | Ensures even force distribution, reducing deformation |

| Clamping Force | Adjust based on part rigidity (e.g., 100–500 N for low-rigidity parts) | Prevents excessive deformation while securing the part |

| Clamping Method | Use vacuum chucks or soft jaws for delicate parts | Minimizes localized stress and surface damage |

Effective clamping requires precise control. For example, excessive clamping force (>1000 N) on parts with wall thicknesses below 1 mm can cause deflections exceeding 0.05 mm, compromising dimensional accuracy.

Heat Treatment Timing and Techniques

Heat treatment, such as quenching and artificial aging, induces thermal and phase-transformation stresses that can deform thin-walled parts. Strategic timing and methods are crucial to minimize these effects while preserving mechanical properties.

- Timing of Heat Treatment: Conducting heat treatment before rough machining reduces residual stresses in the blank material. For instance, annealing at 700–800°C for 1–2 hours can relieve initial stresses without compromising strength.

- Stress Management: Post-heat treatment, parts should be cooled slowly (e.g., at 50°C/hour) to minimize thermal gradients, which can cause distortions of up to 0.2 mm in thin-walled structures.

- Mechanical Property Preservation: Heat treatment must balance stress relief with maintaining tensile strength (typically 900–1100 MPa for Ti-6Al-4V alloys) and hardness (32–38 HRC).

By scheduling heat treatment early and controlling cooling rates, manufacturers can reduce deformation while ensuring the part meets performance specifications.

Machining Processes and Cutting Fluid Selection

The machining process for thin-walled titanium alloys requires careful planning to address the material’s low thermal conductivity (6–8 W/m·K) and high chemical reactivity. Optimized strategies and cutting fluid selection enhance efficiency and precision.

- Process Planning: Sequence operations to machine deformation-prone areas last. For example, rough milling should leave a machining allowance of 0.5–1 mm to account for subsequent finishing passes.

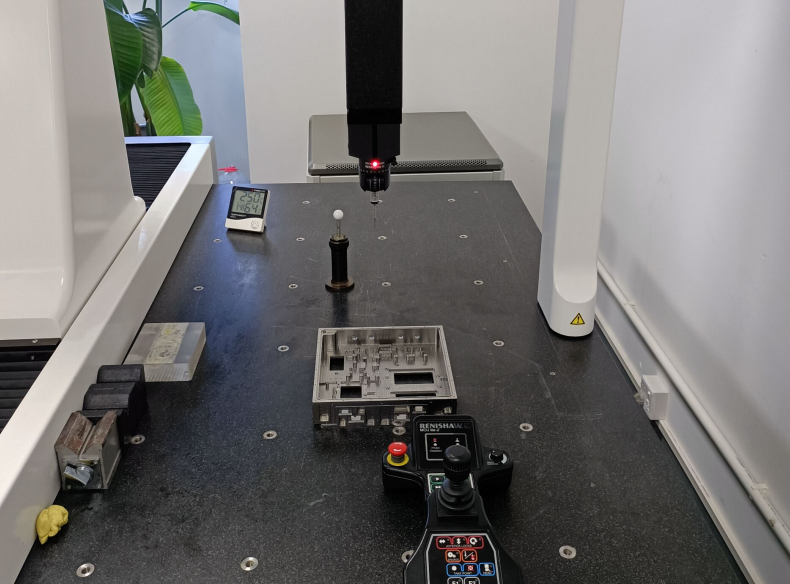

- Reference Surface Adjustment: Continuously monitor and adjust the reference surface during machining, as material removal alters the part’s geometry. Laser scanning or CMM (Coordinate Measuring Machine) can maintain reference accuracy within 0.02 mm.

- Cutting Fluid: Use water-based emulsions or chlorinated oils for titanium alloys to reduce cutting temperatures (which can exceed 600°C) and tool wear. A flow rate of 10–15 L/min ensures effective cooling.

High-speed CNC machines with spindle speeds of 10,000–15,000 RPM and carbide tools coated with TiAlN are recommended for titanium alloys to achieve surface finishes of Ra 0.8–1.6 µm.

Residual Stress Management and Elimination

Residual stresses in thin-walled titanium alloy parts arise from blank material processing and machining. These stresses cause deformation and affect dimensional stability, necessitating advanced prediction and elimination techniques.

| Stress Elimination Method | Description | Benefits | Limitations |

|---|---|---|---|

| Deep Cryogenic Treatment | Submerging parts in liquid nitrogen (-196°C) for 12–24 hours | Reduces residual stress by 50–70%, improves hardness by 10–15% | High equipment cost |

| Vibration Aging | Applying mechanical vibrations (50–100 Hz) for 30–60 minutes | Reduces stress by 20–40%, cost-effective | Less effective for complex geometries |

| Annealing | Heating to 500–600°C for 1–2 hours, followed by slow cooling | Relieves stress and improves ductility | May alter mechanical properties |

Finite element analysis (FEA) is widely used to predict residual stress distribution and deformation. For example, FEA models can simulate stress levels up to 200 MPa in thin-walled parts and predict springback within 0.05 mm accuracy. Deep cryogenic treatment is particularly effective, reducing residual stresses by up to 70% while enhancing wear resistance and dimensional stability.

Conclusion

Machining high-precision thin-walled titanium alloy parts requires a multifaceted approach addressing structural design, clamping, heat treatment, machining processes, and residual stress management. By adopting symmetrical designs, optimized clamping, strategic heat treatment, tailored machining strategies, and advanced stress elimination techniques like deep cryogenic treatment, manufacturers can achieve tight tolerances (e.g., ±0.01 mm) and meet stringent performance requirements. These strategies, supported by tools like FEA and high-performance CNC systems, ensure both quality and efficiency in titanium alloy machining.