High-temperature stainless steels, such as 4Cr14Ni14W2Mo, are vital in aerospace, aviation, and energy industries due to their high hardness at elevated temperatures, structural stability, resistance to high-temperature oxidation, low thermal expansion, and excellent thermal fatigue resistance. These properties make 4Cr14Ni14W2Mo suitable for critical components like turbine engine parts and gas turbines. However, these same characteristics create significant machining challenges, including high cutting forces, tool wear, and poor surface quality. Conventional turning struggles to meet the precision and efficiency demands for such parts. High-speed machining, with benefits like reduced cutting forces and improved surface quality, offers a solution, but optimal parameters for 4Cr14Ni14W2Mo remain underexplored. This article presents an experimental study on turning 4Cr14Ni14W2Mo, detailing material properties, machining difficulties, experimental setup, and optimized cutting parameters for high-quality, efficient machining.

Material Properties and Machining Difficulties

4Cr14Ni14W2Mo is a high-temperature stainless steel with high strength, hardness, plasticity, and toughness. Its composition includes chromium, nickel, tungsten, and molybdenum, enhancing its performance in extreme conditions. These properties, while beneficial for component durability, pose significant machining challenges:

- High Cutting Forces: The material’s high hardness and strength result in significant cutting forces, increasing tool stress.

- High Cutting Temperatures: Low thermal conductivity causes heat to concentrate at the tool tip, as most deformation energy converts to heat rather than dissipating.

- Short Tool-Chip Contact Length: This increases contact stress on the cutting edge, accelerating wear.

- Work Hardening: High plasticity and toughness lead to significant cutting deformation, causing lattice distortion and work hardening, which further complicates machining.

- Severe Tool Wear: The material’s hard phases, such as carbides, cause abrasive wear, while work hardening leads to boundary wear. Oxidation and diffusion wear also occur due to high temperatures.

These factors result in rapid tool wear, poor surface quality, and low machining efficiency, necessitating optimized tools and parameters.

Experimental Setup

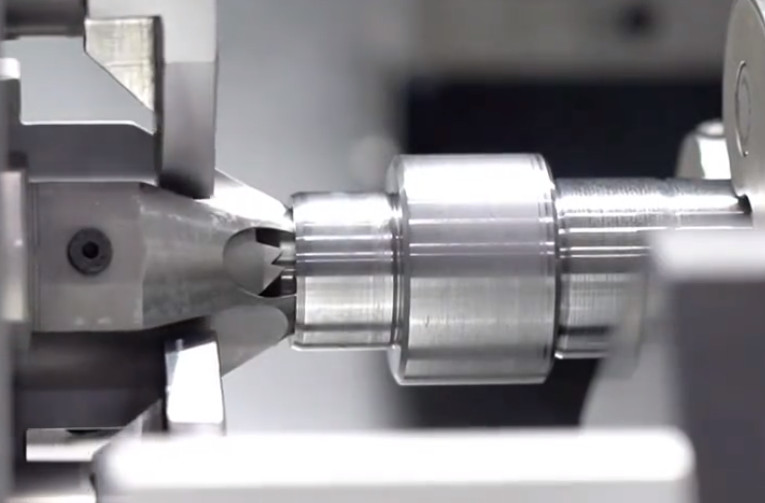

To address these challenges, a turning experiment was conducted using a typical rotary part as a test piece. The setup, including material, equipment, tools, and parameters, was carefully designed to study 4Cr14Ni14W2Mo’s machining behavior.

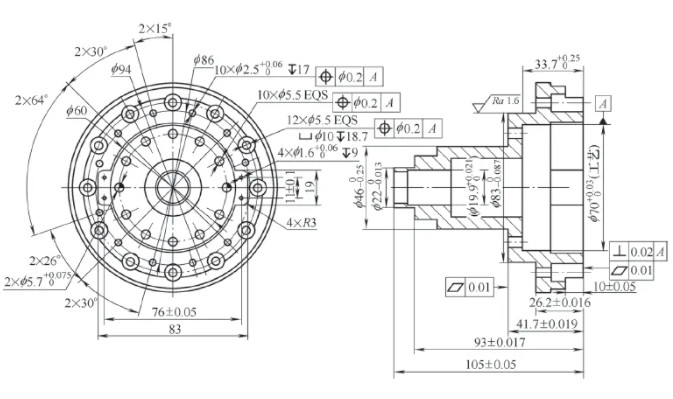

Test Material and Part

The test material was a 4Cr14Ni14W2Mo round bar with dimensions φ170 mm × 200 mm. A typical shaft component was selected for the turning trials, representing common geometries in aerospace and energy applications. The part required high dimensional accuracy and surface quality, making it suitable for evaluating machining performance.

Equipment Selection

The experiment was conducted on a CY6140 lathe, chosen for its compatibility with the part’s dimensions and precision requirements. The lathe’s power, rigidity, and speed capabilities were adequate for the trials, ensuring stable machining conditions.

Tool Selection

Tool geometry significantly affects machining efficiency, tool life, surface roughness, cutting forces, and work hardening. Based on ISO513 standard (material group M14), two tool inserts were selected: CCMG 120408-NR IC907 for roughing and CCMG 120404-TF IC907 for semi-finishing and finishing. The CCMG 120408-NR IC907 has a 0.4 mm chamfered edge to enhance strength under high cutting forces, while the CCMG 120404-TF IC907 features a positive rake angle and a large arc chip-breaking groove to reduce work hardening and improve chip evacuation.

Cutting Parameters

Cutting parameters were determined based on the lathe’s capabilities, material properties, and prior machining issues. Parameters were selected to balance dimensional accuracy, tool life, and surface quality. The trials included variations in spindle speed, cutting depth, and feed rate to identify optimal settings.

Turning Experiments

Six turning trials were conducted to evaluate the effects of different parameters and tools on machining performance. The trials assessed chip morphology, surface roughness, tool condition, and machining stability. The results are summarized below.

| Trial | Operation | Spindle Speed (r/min) | Cutting Depth (mm) | Feed Rate (mm/r) | Chip Morphology | Surface Roughness (Ra) | Tool Condition | Observations |

|---|---|---|---|---|---|---|---|---|

| 1 | External Turning | 200 | 2.0 | 0.2 | C-shaped, dark yellow | High | No wear | High heat, poor surface quality |

| 2 | External Turning | 260 | 2.0 | 0.2 | C-shaped, golden | High | Tip blackened | Heat concentrated at tip, poor surface quality |

| 3 | External Turning | 170 | 2.5 | 0.2 | Fragmented, dark yellow | Very high | Tip worn | Unstable, uneven surface |

| 4 | External Turning | 250 | 1.5 | 0.15 | Spring-shaped | Low | No wear | Stable, good surface quality |

| 5 | Grooving | 200 | 1.0 | 0.1 | Ribbon-shaped | Low | No wear after 10 grooves | Stable, high tool durability |

| 6 | Face Grooving | 400 | 1.0 | 0.1 | Tower-shaped | Moderate | No wear | Stable, moderate surface quality |

Trial Analysis

Trial 1: External turning at 200 r/min and 2.0 mm depth produced C-shaped, dark yellow chips, indicating high cutting heat. Surface quality was poor due to chip impact on the tool’s flank or workpiece surface, though the tool showed no wear.

Trial 2: Increasing spindle speed to 260 r/min resulted in golden C-shaped chips and a blackened tool tip, suggesting heat concentration at the tip. Surface quality remained poor, with no tool wear observed.

Trial 3: Reducing speed to 170 r/min and increasing depth to 2.5 mm caused machine vibration, fragmented chips, and tool tip wear. The surface was uneven, indicating unstable cutting and unsuitable parameters.

Trial 4: Using a different external turning tool at 250 r/min and 1.5 mm depth produced spring-shaped chips and low surface roughness (Ra). The process was stable, with no tool wear, indicating suitable parameters.

Trial 5: Grooving at 200 r/min and 1.0 mm depth resulted in ribbon-shaped chips, low Ra, and stable cutting. The tool showed no wear after 10 grooves, demonstrating high durability.

Trial 6: Face grooving at 400 r/min (due to smaller diameter) and 1.0 mm depth produced tower-shaped chips. The process was stable, but Ra was moderate due to three-sided tool loading.

Optimized Cutting Parameters

Based on the trials, optimal cutting parameters for 4Cr14Ni14W2Mo were determined for roughing and finishing operations using the selected tools. The CCMG 120408-NR IC907, with its chamfered edge, is ideal for roughing due to its strength under high cutting forces. The CCMG 120404-TF IC907, with a positive rake angle and chip-breaking groove, is suited for semi-finishing and finishing, minimizing work hardening and improving chip evacuation. Optimized parameters are shown below.

| Operation | Tool Insert | Spindle Speed (r/min) | Cutting Depth (mm) | Feed Rate (mm/r) |

|---|---|---|---|---|

| Roughing | CCMG 120408-NR IC907 | 200–250 | 1.5–2.0 | 0.15–0.2 |

| Semi-finishing/Finishing | CCMG 120404-TF IC907 | 250–300 | 0.5–1.0 | 0.1–0.15 |

Conclusion

The experimental study on turning 4Cr14Ni14W2Mo high-temperature stainless steel provided insights into its machining behavior. By analyzing chip morphology (e.g., C-shaped, spring-shaped, ribbon-shaped) and its impact on cutting forces and surface roughness, optimal parameters were established. The trials confirmed that the CCMG 120408-NR IC907 and CCMG 120404-TF IC907 inserts, combined with specific spindle speeds, cutting depths, and feed rates, achieve high-quality and efficient machining. These findings address the challenges of high cutting forces, tool wear, and poor surface quality, enabling effective processing of 4Cr14Ni14W2Mo for critical applications.