This article provides a comprehensive comparison of UG (Unigraphics NX) and Cimatron programming for machining Hastelloy impellers. Hastelloy, a nickel-based superalloy, is widely used in aerospace, chemical processing, and power generation due to its excellent corrosion resistance and high-temperature strength. Impellers, critical components in turbomachinery, require precise machining to achieve complex geometries and tight tolerances. UG and Cimatron are two prominent CAM software solutions for generating CNC toolpaths. This comparison focuses on technical parameters, toolpath strategies, and practical considerations to assist manufacturers in selecting the appropriate software for Hastelloy impeller machining.

Overview of UG and Cimatron Software

UG, developed by Siemens PLM Software, is a fully integrated CAD/CAE/CAM system known for its versatility in handling complex geometries and advanced manufacturing processes. It supports 2D to 5-axis machining and is widely used in industries requiring high-precision components. Cimatron, developed by 3D Systems, is a CAD/CAM solution tailored for mold, die, and complex part manufacturing, with strengths in surface machining and 5-axis toolpath generation. Both software packages offer robust capabilities for impeller machining, but their approaches differ in user interface, toolpath algorithms, and post-processing.

For Hastelloy impeller machining, both UG and Cimatron must address material-specific challenges, such as high hardness (typically 30-40 HRC), low thermal conductivity, and work hardening tendencies. These properties necessitate optimized toolpaths, appropriate cutting parameters, and specialized tooling to minimize tool wear and ensure surface quality.

Toolpath Strategies for Hastelloy Impeller Machining

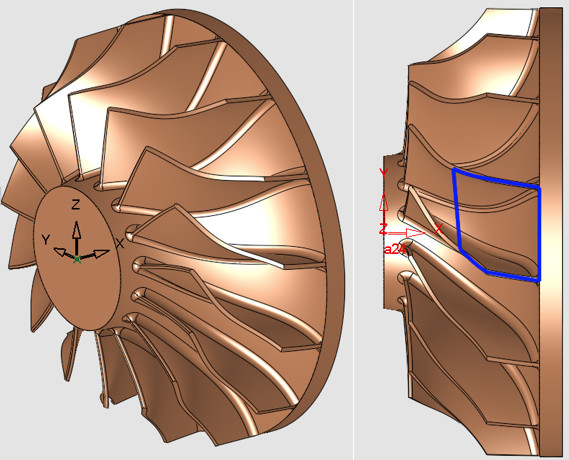

Impellers typically feature complex, curved geometries, including blades, hubs, and flow channels, requiring multi-axis machining. UG and Cimatron offer distinct toolpath strategies to address these requirements.

UG Toolpath Strategies

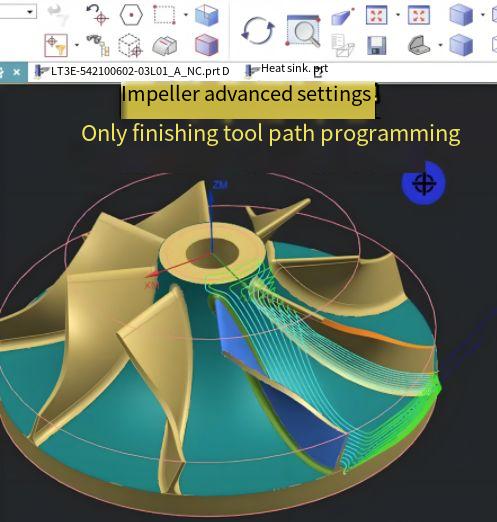

UG provides a range of toolpath options for impeller machining, including:

- Streamline Machining: Ideal for blade surfaces, this strategy generates smooth, continuous toolpaths following the natural flow of the impeller geometry. It minimizes sudden directional changes, reducing tool wear and improving surface finish.

- Variable-Axis Contour: Used for hub and shroud machining, this allows dynamic tool orientation to maintain optimal cutting angles, critical for deep, narrow channels.

- Multi-Blade Machining: A specialized module for impellers, enabling simultaneous machining of multiple blades with 5-axis control. It supports parameters like lead angle (5-15°) and tilt angle (0-30°) for precise blade profiling.

UG’s toolpaths are highly customizable, with parameters such as step-over (0.05-0.2 mm), cutting tolerance (0.01-0.05 mm), and feed rate (50-150 m/min for Hastelloy). These settings allow fine-tuning to balance machining time and surface quality.

Cimatron Toolpath Strategies

Cimatron excels in surface-based machining, offering toolpaths tailored for impeller geometries:

- Wrap Contour (Wcut): A 3+2 axis strategy for blade machining, wrapping toolpaths around curved surfaces. It uses a constant step-over (0.1-0.3 mm) and supports scallop height control (0.005-0.02 mm).

- 5-Axis Flowline: Generates smooth, continuous toolpaths for complex surfaces, with dynamic tool axis control to avoid collisions in tight areas.

- Projection Machining: Projects toolpaths along user-defined curves, suitable for finishing blade edges with high precision.

Cimatron’s algorithms prioritize surface quality, with parameters like toolpath smoothing radius (0.1-0.5 mm) and minimum cut length (0.2-1 mm) to reduce vibration and tool deflection during Hastelloy machining.

Comparison of Toolpath Efficiency

UG’s multi-blade module is highly efficient for impellers with repetitive blade patterns, reducing programming time by up to 30% compared to individual blade programming. Cimatron’s strength lies in its surface machining, achieving superior surface finishes (Ra 0.4-0.8 µm) with fewer toolpath segments. However, Cimatron may require additional setup time for complex 5-axis toolpaths due to its less intuitive parameter interface compared to UG.

Cutting Parameters for Hastelloy Machining

Hastelloy’s material properties demand careful selection of cutting parameters to prevent excessive tool wear and ensure dimensional accuracy. Below is a comparison of typical parameters used in UG and Cimatron for impeller machining.

| Parameter | UG | Cimatron |

|---|---|---|

| Cutting Speed (Vc) | 30-50 m/min | 25-45 m/min |

| Feed Rate (Fz) | 0.02-0.05 mm/tooth | 0.015-0.04 mm/tooth |

| Depth of Cut (Ap) | 0.1-0.5 mm | 0.08-0.4 mm |

| Tool Diameter | 6-12 mm (ball end mill) | 4-10 mm (ball end mill) |

| Coolant | High-pressure emulsion (70-100 bar) | High-pressure emulsion (60-90 bar) |

UG allows precise control over cutting parameters, with built-in material libraries that recommend settings for Hastelloy grades (e.g., C-276, X). Cimatron’s parameter interface is less comprehensive but includes templates for superalloys, simplifying setup for less experienced programmers. Both software packages support adaptive machining strategies, adjusting feed rates dynamically to maintain constant chip load, critical for minimizing tool wear in Hastelloy.

Post-Processing and Machine Integration

Post-processing converts CAM toolpaths into machine-specific NC code. UG and Cimatron differ in their post-processing capabilities and integration with CNC machines.

UG Post-Processing

UG’s Post Builder supports a wide range of machine controllers (e.g., Siemens, Fanuc, Heidenhain) and allows customization of NC code for 5-axis machines. It includes features like:

- Toolpath verification with machine simulation to detect collisions.

- Support for non-linear rotary axes, common in impeller machining.

- Output formats like G-code and CL data, with cycle time estimates.

UG’s post-processors are highly reliable, with minimal manual editing required, reducing setup time by approximately 20% compared to generic post-processors.

Cimatron Post-Processing

Cimatron’s post-processing is robust for mold and die applications but less flexible for complex 5-axis impeller machining. It supports standard controllers but may require custom post-processors for advanced machines. Key features include:

- Basic machine simulation for toolpath validation.

- Support for 3+2 and simultaneous 5-axis machining.

- Output optimization for surface finish, reducing dwell marks.

Cimatron’s post-processors may need additional tweaking for Hastelloy impeller machining, particularly for machines with non-standard kinematics, increasing setup time by 10-15% compared to UG.

Programming Workflow and User Expertise

The programming workflow and required expertise influence software suitability for Hastelloy impeller machining.

UG Workflow

UG’s workflow is systematic, starting with CAD model preparation, followed by machining environment setup, toolpath generation, and post-processing. Key steps include:

- Defining machining coordinates and safety planes.

- Selecting templates for impeller-specific operations.

- Simulating toolpaths with material removal analysis.

UG’s interface is complex, with a learning curve of 6-12 months for proficiency in 5-axis impeller programming. However, its extensive documentation and community support reduce training time.

Cimatron Workflow

Cimatron’s workflow is streamlined for surface machining, with a focus on mold and die applications. Steps include:

- Importing surface geometry and defining machining zones.

- Applying pre-defined toolpath templates for blades and hubs.

- Validating toolpaths with basic simulation.

Cimatron is easier to learn for surface-based machining, with a learning curve of 3-6 months. However, its limited support for complex solid modeling may require external CAD preparation for intricate impellers.

Practical Considerations

Several practical factors influence the choice between UG and Cimatron for Hastelloy impeller machining:

- Software Cost: UG is a premium solution with higher licensing fees, while Cimatron is more cost-effective for small to medium enterprises.

- Hardware Requirements: UG demands high-performance workstations (e.g., 32-64 GB RAM, multi-core CPUs), while Cimatron runs efficiently on mid-range systems (16-32 GB RAM).

- Industry Adoption: UG is prevalent in aerospace and automotive industries, while Cimatron is common in mold and die manufacturing.

Both software packages support Hastelloy impeller machining, but UG’s broader industry adoption and integration capabilities make it preferable for large-scale production, while Cimatron’s cost and ease of use suit smaller workshops.

Conclusion

UG and Cimatron are both capable of programming Hastelloy impeller machining, but their strengths cater to different needs. UG excels in handling complex geometries, offering advanced toolpath strategies, and seamless post-processing, making it ideal for high-precision, large-scale production. Cimatron shines in surface machining, delivering excellent surface finishes with a shorter learning curve, suitable for smaller operations. Manufacturers should evaluate their production scale, budget, and technical expertise to choose the most appropriate software. By optimizing toolpaths and cutting parameters, both UG and Cimatron can achieve high-quality Hastelloy impellers, meeting the stringent demands of critical applications.