USA precision machining delivers high-accuracy, reliable components for industries such as aerospace, automotive, medical, and defense. This article explores the technical aspects, processes, materials, and quality standards that define precision machining in the USA, providing a detailed overview for professionals seeking dependable manufacturing solutions.

What is Precision Machining?

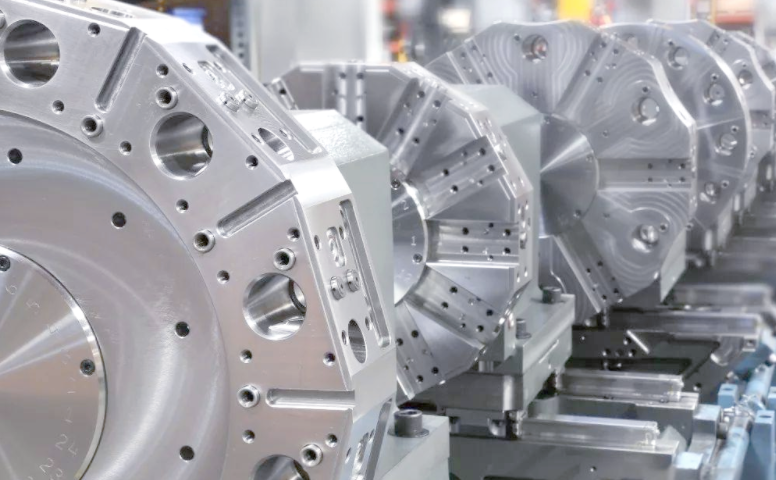

Precision machining is a manufacturing process that uses advanced tools and computer-controlled equipment to produce parts with tight tolerances, often within ±0.0001 inches (±0.00254 mm). It involves subtractive manufacturing techniques, where material is removed from a workpiece to achieve the desired shape, size, and surface finish. In the USA, precision machining is synonymous with CNC (Computer Numerical Control) technology, which ensures repeatability and accuracy.

Key processes include milling, turning, drilling, grinding, and electrical discharge machining (EDM). These methods cater to complex geometries and high-performance materials, meeting the demands of industries requiring exact specifications.

Core Processes in USA Precision Machining

Precision machining encompasses several processes, each suited to specific applications. Below are the primary methods used in the USA:

CNC Milling

CNC milling uses rotating cutting tools to remove material from a stationary workpiece. It is ideal for creating slots, pockets, and complex 3D surfaces. Modern CNC milling machines feature 3-axis, 4-axis, or 5-axis configurations, with 5-axis machines offering superior flexibility for intricate parts. Typical tolerances range from ±0.001 inches (±0.0254 mm) to ±0.0001 inches (±0.00254 mm).

CNC Turning

CNC turning rotates the workpiece against a stationary cutting tool to produce cylindrical parts like shafts, bolts, and bushings. Lathes equipped with live tooling can also perform milling operations, enhancing efficiency. Tolerances for turning often reach ±0.0005 inches (±0.0127 mm), with surface finishes as fine as Ra 0.4 µm.

Electrical Discharge Machining (EDM)

EDM uses electrical sparks to erode material, suitable for hard metals and complex shapes unachievable by traditional methods. Wire EDM and sinker EDM are common, with tolerances as tight as ±0.0002 inches (±0.00508 mm). This process is prevalent in mold-making and aerospace applications.

Grinding

Grinding employs abrasive wheels to achieve ultra-smooth surfaces and tight tolerances, often below ±0.0001 inches (±0.00254 mm). It is used for finishing components like gears and turbine blades, ensuring high precision and surface quality.

Materials Used in Precision Machining

USA precision machining handles a wide range of materials, each chosen based on application requirements. Below is a table summarizing common materials and their properties:

| Material | Properties | Applications |

|---|---|---|

| Aluminum (6061, 7075) | Lightweight, corrosion-resistant, good strength-to-weight ratio | Aerospace components, automotive parts |

| Stainless Steel (304, 316) | High corrosion resistance, durable | Medical devices, food processing equipment |

| Titanium (Grade 5) | High strength, low weight, biocompatible | Medical implants, aerospace fasteners |

| Inconel | Heat and corrosion resistance | Turbine blades, exhaust systems |

| Plastics (PEEK, Delrin) | Chemical resistance, low friction | Insulators, medical components |

Material selection depends on factors like mechanical properties, environmental conditions, and cost. For example, aluminum 6061 is favored for its machinability, while titanium is chosen for high-strength, lightweight applications despite its higher cost.

Quality Control in Precision Machining

Quality control is critical in USA precision machining to ensure parts meet stringent specifications. Common standards include ISO 9001:2015 and AS9100D (aerospace-specific). Key quality control methods include:

- Coordinate Measuring Machines (CMM): CMMs measure part dimensions with accuracies up to ±0.00005 inches (±0.00127 mm), ensuring compliance with design specifications.

- Surface Profilometry: Measures surface roughness, achieving finishes as low as Ra 0.2 µm for critical applications.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing and X-ray inspection detect internal defects without damaging parts.

- Statistical Process Control (SPC): Monitors production processes to maintain consistency, using control charts to track variables like tool wear.

Traceability is also emphasized, with manufacturers maintaining detailed records of material batches, machining parameters, and inspection results to ensure compliance with industry regulations.

Applications of Precision Machining in the USA

Precision machining serves diverse industries, each with unique requirements. Below are key applications:

Aerospace

Aerospace components, such as turbine blades and landing gear parts, require tolerances as tight as ±0.0001 inches (±0.00254 mm) and materials like titanium and Inconel. Machining processes must comply with AS9100D standards to ensure safety and reliability.

Medical

Medical devices, including implants and surgical tools, demand biocompatible materials like titanium and PEEK. Precision machining ensures smooth surfaces (Ra 0.4 µm or better) to prevent bacterial adhesion and ensure patient safety.

Automotive

Automotive parts like engine components and transmission gears require high durability and precise tolerances (±0.001 inches or ±0.0254 mm). Materials like stainless steel and aluminum are commonly used for their strength and weight advantages.

Defense

Defense applications include weapon components and radar systems, where precision machining ensures reliability under extreme conditions. Materials like Inconel and hardened steels are prevalent due to their robustness.

Key Considerations in Precision Machining

While precision machining offers significant advantages, certain considerations must be addressed to ensure optimal outcomes:

- Tool Wear: High-speed machining of hard materials like titanium can accelerate tool wear, requiring regular tool replacement or advanced coatings like TiN (Titanium Nitride) to extend tool life.

- Thermal Expansion: Materials expand during machining due to heat, potentially affecting tolerances. Coolant systems and temperature-controlled environments mitigate this issue.

- Setup Time: Complex parts require precise fixturing and programming, increasing setup time. Multi-axis CNC machines and CAD/CAM software reduce setup complexity.

- Cost Management: High-precision processes and exotic materials increase costs. Manufacturers balance cost by optimizing toolpaths and minimizing material waste.

Why Choose USA Precision Machining?

USA-based precision machining offers several advantages:

- Advanced Technology: USA shops utilize state-of-the-art CNC machines, such as 5-axis mills and Swiss-style lathes, for unmatched accuracy.

- Skilled Workforce: The USA has a highly trained workforce proficient in CNC programming, quality control, and material science.

- Regulatory Compliance: Strict adherence to standards like ISO 9001 and AS9100 ensures reliability for critical applications.

- Supply Chain Efficiency: Domestic production reduces lead times and shipping costs compared to overseas manufacturing.

These factors make USA precision machining a preferred choice for industries requiring high-quality, reliable components.

Selecting a Precision Machining Partner

Choosing the right machining partner is critical for project success. Key criteria include:

| Criteria | Description |

|---|---|

| Certifications | Look for ISO 9001:2015, AS9100D, or ITAR compliance for quality and security. |

| Equipment | Ensure the shop has modern CNC machines, such as 5-axis mills or EDM systems. |

| Experience | Verify expertise in your industry (e.g., aerospace, medical) and material handling. |

| Quality Assurance | Confirm use of CMM, NDT, and SPC for consistent quality control. |

Additionally, evaluate the partner’s ability to handle small-batch prototyping or high-volume production based on your needs. Request case studies or references to assess their track record.

Conclusion

USA precision machining delivers high-accuracy, reliable components for industries with demanding requirements. By leveraging advanced CNC technology, stringent quality control, and a wide range of materials, USA manufacturers meet the needs of aerospace, medical, automotive, and defense sectors. Understanding the processes, materials, and considerations involved ensures informed decisions when selecting a machining partner. With its technical expertise and robust infrastructure, the USA remains a leader in precision machining solutions.