In engineering projects, whether involving pipeline systems, equipment integration, or automated control, valves are indispensable components. Their design, precision, and material composition must align with specific operating conditions, media, and control requirements. While often overlooked, critical valve components such as balls, spools, stems, seats, and flanges rely heavily on CNC (Computer Numerical Control) machining to achieve the necessary accuracy, especially in applications demanding robust sealing, precise actuation, or high-pressure corrosion resistance.

As industrial automation and control systems advance, the demand for valves with superior precision and consistency has surged. CNC machining has become a cornerstone of valve manufacturing, enabling the production of complex, high-quality components for both standard and customized designs. Whether you’re involved in procurement, design, or manufacturing, understanding common valve types, their applications, and the role of CNC machining can enhance decision-making, optimize costs, and ensure project success.

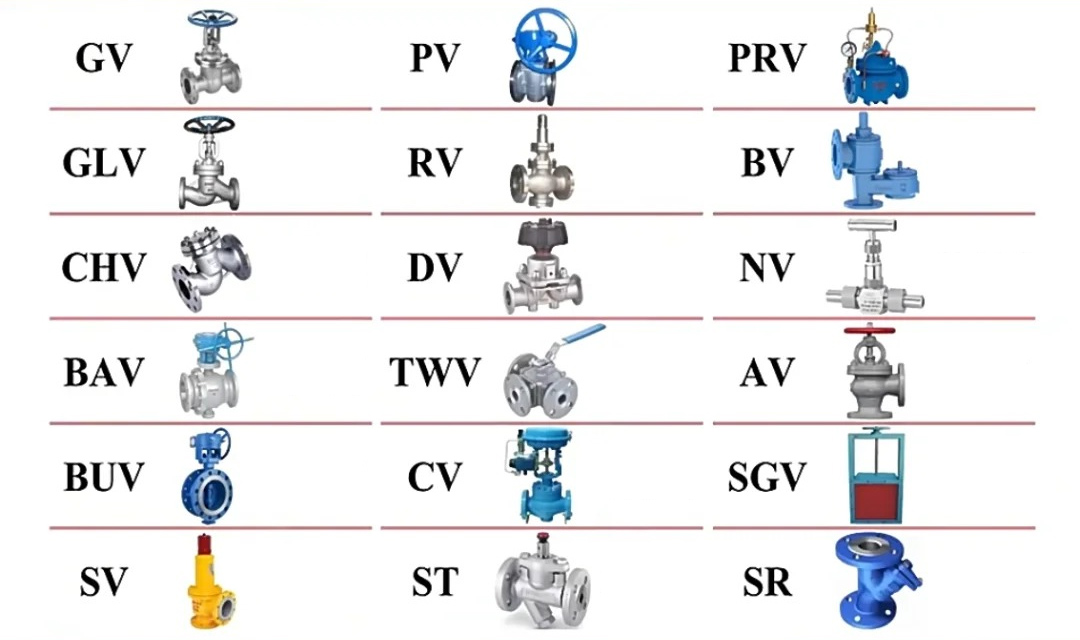

Common Valve Types and Their CNC-Machined Components

Valves come in various types, each tailored to specific functions and operating conditions. CNC machining is primarily used to produce critical components such as valve bodies, spools, stems, seats, and connection flanges. The structure and precision requirements of these components vary depending on the valve type. Below is a detailed overview of common valve types, their CNC-machined parts, and their application characteristics.

Valve Type Overview

The table below summarizes key valve types, their CNC-machined components, and their primary applications:

| Valve Type | Common CNC-Machined Components | Application Features |

|---|---|---|

| Ball Valve | Ball, Stem, Seat | Fast opening/closing, ideal for on/off control, excellent sealing |

| Gate Valve | Gate, Stem, Body | Suitable for high-flow conditions, low resistance, simple structure |

| Globe Valve | Disc, Seat, Bonnet | High precision for flow regulation, suitable for small diameters |

| Butterfly Valve | Disc, Body, Shaft | Lightweight, ideal for ventilation systems or large-diameter low-pressure applications |

| Check Valve | Disc, Guide, Spring Seat | Prevents backflow, commonly used at pump outlets |

| Safety Valve | Spring, Stem, Guide Structure | Automatically relieves excess pressure to ensure system safety |

| Control Valve | Spool, Guide Sleeve, Connectors | Precise flow regulation for automated control systems |

| Needle Valve | Needle, Threaded Seat, Body | High adjustability, suitable for small-flow or experimental settings |

| Vacuum/Sanitary Valve | Sealing Ring, Polished Cavity, Mirror-Finish Spool | Used in cleanrooms, biopharmaceuticals, and electronics industries |

CNC Machining Considerations for Valve Components

Each valve type imposes unique demands on CNC machining. For instance:

- Ball Valves: The ball requires spherical machining with a surface finish of Ra 0.4–0.8 µm and a sphericity tolerance of ±0.01 mm to ensure leak-tight sealing.

- Gate Valves: The gate’s sealing surfaces demand flatness within ±0.02 mm, achieved through precision milling or grinding.

- Globe Valves: The disc and seat require precise angular machining (e.g., 30°–45° sealing angles) to optimize flow control.

- Sanitary Valves: Internal surfaces need mirror polishing (Ra 0.2 µm) to meet hygiene standards, often requiring CNC-controlled electropolishing.

Machining processes typically include turning, milling, drilling, grinding, and polishing, performed on 3- to 5-axis CNC machines to achieve complex geometries and tight tolerances.

Industry-Specific Valve Applications

Different industries have distinct valve requirements, influenced by operating conditions, regulatory standards, and material preferences. Understanding these applications helps in selecting the right valve type and optimizing CNC machining processes.

Oil and Gas Industry

Common Valves: API-standard ball valves, high-pressure gate valves, check valves, fire-safe valves

Applications: Used in oil and gas pipelines for on/off control, explosion-proofing, corrosion resistance, and high-pressure operation. These valves are often deployed in remote or unmanned conditions.

CNC Machining Notes: Components like valve bodies and balls are machined from materials like 316 stainless steel or Inconel, with tolerances of ±0.015 mm for flange connections. Cutting speeds for 316 SS are typically 50–70 m/min, with a feed rate of 0.1–0.2 mm/rev.

Chemical and Fine Chemical Industry

Common Valves: Fluorine-lined ball valves, diaphragm valves, bellows-sealed globe valves

Applications: Designed for acid/alkali resistance and long-term operation at high temperatures, with a focus on leak prevention and corrosion resistance.

CNC Machining Notes: Diaphragm valve bodies require precise milling of internal cavities (Ra 0.8 µm finish) to accommodate PTFE linings. Threaded seats are machined with a cutting speed of 30–50 m/min to avoid material galling.

Power Generation Industry

Common Valves: High-temperature/high-pressure globe valves, power station gate valves, safety valves

Applications: Used in boiler steam systems, pressure vessel inlets/outlets, and emergency exhaust systems.

CNC Machining Notes: Safety valve springs and stems are machined from high-strength alloys like 17-4 PH, with a surface finish of Ra 0.4 µm. Turning parameters include a cutting speed of 80–120 m/min and a feed rate of 0.1–0.15 mm/rev.

Municipal and Water Treatment

Common Valves: Resilient-seated gate valves, flanged butterfly valves, silent check valves

Applications: Employed in water supply networks, wastewater treatment, pump stations, and stormwater management.

CNC Machining Notes: Butterfly valve discs require profile milling to achieve a taper angle of 5°–10°, with a tolerance of ±0.02 mm. Milling parameters include a cutting speed of 70–100 m/min and a feed rate of 0.15–0.3 mm/tooth.

Food and Pharmaceutical Industry

Common Valves: Sanitary quick-connect ball valves, diaphragm valves, clamp butterfly valves

Applications: Meet CIP/SIP cleaning requirements, ensure sterility, and allow easy disassembly while resisting corrosion.

CNC Machining Notes: Valve cavities are polished to Ra 0.2 µm using CNC-controlled electropolishing. Components are machined from 316L stainless steel with a cutting speed of 60–90 m/min.

Cleanrooms, Laboratories, and Electronics

Common Valves: Gas needle valves, vacuum valves, proportional valves

Applications: Control high-purity gases, vacuum systems, and airflow regulation in sensitive environments.

CNC Machining Notes: Needle valve needles require precision turning with a tolerance of ±0.005 mm for the tip diameter. Grinding parameters include a cutting speed of 20–30 m/min to achieve a mirror finish.

Valve Classification by Function

Navigating the variety of valve types can be overwhelming. A practical approach is to classify valves by their primary function—i.e., what they are designed to do in a system. This perspective simplifies selection and highlights the role of CNC machining in meeting functional requirements.

Functional Categories and Examples

The table below categorizes valves by function, listing common types and their roles:

| Function | Common Valve Types | Description |

|---|---|---|

| On/Off Control | Ball Valve, Gate Valve, Globe Valve, Butterfly Valve | Most common, used to fully open or close flow |

| Flow/Pressure Regulation | Control Valve, Needle Valve, V-Port Ball Valve | Precisely controls flow rate or pressure |

| Backflow Prevention | Check Valve (Lift, Swing) | Prevents reverse flow, typically installed after pumps or gas sources |

| Overpressure Protection | Safety Valve, Relief Valve | Automatically opens to relieve excess pressure |

| Flow Diversion/Switching | Three-Way Valve, Plug Valve, Multi-Port Valve | Redirects flow between multiple paths |

| Pneumatic Control | Pneumatic Ball Valve, Pneumatic Butterfly Valve | Integrated with PLC/gas source control systems |

| Electric/Automated Control | Electric Control Valve, Solenoid Valve | Operates via electrical signals for remote control |

| Vacuum/Clean Applications | Vacuum Isolation Valve, Sanitary Valve | Ensures contamination-free operation in sensitive environments |

| Micro-Flow Regulation | Needle Valve, Electric Proportional Valve | High-precision adjustment for experimental or precise applications |

CNC Machining for Functional Precision

Each functional category demands specific machining techniques:

- On/Off Valves: Require robust components like valve bodies and stems, machined with tolerances of ±0.02 mm for reliable sealing. Turning parameters include a cutting speed of 80–120 m/min and a feed rate of 0.2–0.4 mm/rev.

- Control Valves: Spools and guide sleeves need precision milling to achieve gap tolerances of ±0.01 mm, ensuring smooth actuation.

- Vacuum Valves: Internal surfaces are polished to Ra 0.2 µm using CNC grinding or lapping to prevent particle contamination.

Why CNC Machining Is Critical for Valve Manufacturing

CNC machining is integral to valve production due to its ability to meet stringent requirements for precision, surface quality, material versatility, and complex geometries. Below are the key reasons CNC machining is indispensable:

High Precision

Valves often require extremely tight tolerances, especially for sealing surfaces. For example, ball valve balls must maintain a sphericity of ±0.01 mm and a diameter tolerance of ±0.005 mm to ensure zero leakage. CNC machines, equipped with high-resolution encoders and servo controls, achieve these tolerances consistently.

Example Parameters: For a 316 SS ball, spherical turning is performed at a cutting speed of 60–80 m/min, a feed rate of 0.05–0.1 mm/rev, and a depth of cut of 0.2–0.5 mm. Post-machining lapping ensures a surface finish of Ra 0.4 µm.

Superior Surface Finish

Applications like needle valves and vacuum valves demand mirror-like surface finishes (Ra 0.2–0.4 µm) to minimize friction and contamination. CNC machining, combined with polishing or lapping, delivers these finishes reliably.

Example Parameters: For a vacuum valve spool, CNC grinding is performed at a wheel speed of 25–35 m/min, with a feed rate of 0.01–0.02 mm/pass, followed by diamond paste lapping.

Material Versatility

Valves are made from diverse materials, including stainless steel (316L, 410), titanium alloys, copper alloys, and polymers like PTFE. CNC machines are adaptable, with toolpaths and cutting parameters optimized for each material’s properties.

Example Parameters: For titanium alloy stems, turning is performed at a cutting speed of 40–60 m/min, a feed rate of 0.08–0.12 mm/rev, and a depth of cut of 0.3–0.7 mm, using carbide tools to minimize tool wear.

Complex Geometries

Valves like three-way valves, V-port valves, and proportional valves feature intricate geometries that are impractical for traditional manufacturing methods like stamping. CNC machining, particularly 5-axis milling, enables the production of these complex shapes in small batches.

Example Parameters: For a V-port valve spool, 5-axis milling is used with a cutting speed of 70–100 m/min, a feed rate of 0.1–0.2 mm/tooth, and a step-over of 0.5–1 mm to achieve the V-shaped profile.

Conclusion

Valves are critical to countless engineering applications, from oil pipelines to pharmaceutical cleanrooms. Their diverse types, functions, and industry-specific requirements underscore the importance of understanding their design and manufacturing processes. CNC machining plays a pivotal role in producing high-precision, reliable valve components, meeting the demands of modern industrial systems. By mastering valve types, their applications, and the intricacies of CNC machining, professionals in procurement, design, and manufacturing can make informed decisions, optimize performance, and drive project success.

Frequently Asked Questions (FAQ)

What are the most common valve types used in industrial applications?

Common valve types include ball valves, gate valves, globe valves, butterfly valves, check valves, safety valves, control valves, and needle valves. Each is designed for specific functions, such as on/off control, flow regulation, or backflow prevention, depending on the industry and operating conditions.

Why is CNC machining essential for valve manufacturing?

CNC machining provides the high precision, superior surface finish, material versatility, and ability to produce complex geometries required for valve components. For example, it achieves tolerances of ±0.005 mm for sealing surfaces and surface finishes as fine as Ra 0.2 µm for sanitary applications.

How do material choices affect CNC machining of valves?

Material properties like hardness, corrosiveness, and machinability influence CNC parameters. For instance, stainless steel requires lower cutting speeds (50–70 m/min) to prevent work hardening, while PTFE demands specialized tools to avoid deformation. CNC machines are adaptable to these variations.

What tolerances are achievable for valve components using CNC machining?

CNC machining can achieve tolerances as tight as ±0.005 mm for critical features like ball valve balls or needle valve tips. General tolerances for valve bodies and flanges are typically ±0.02 mm, ensuring reliable performance and assembly.