Hex flange nuts look similar to ordinary hex nuts, but their load-bearing performance is markedly better. The advantage comes from their structural design and the way they work under load.

01. The Compression Limits of Standard Nuts

Standard hex nuts have a basic structure: a hexagonal head with internal threads. Their contact with the workpiece is confined largely to the narrow annulus under the nut. When external force is applied, stress concentrates on this small area. Once the pressure exceeds the material’s limit, three typical failures may occur:

- Surface indentation: the workpiece surface is pressed into dents, especially on softer metals like aluminum or copper.

- Thread stripping: excessive load on the threads can cause slippage and connection failure.

- Loosening under vibration: friction between mating threads alone may be insufficient to maintain stability, reducing effective compressive capacity.

02. The Compression Advantages of Hex Flange Nuts

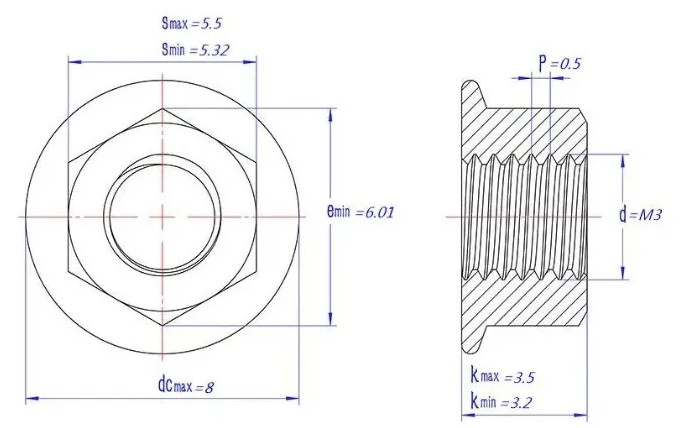

Hex flange nuts add a flange beneath the hex body. This feature is the key to their superior load capacity.

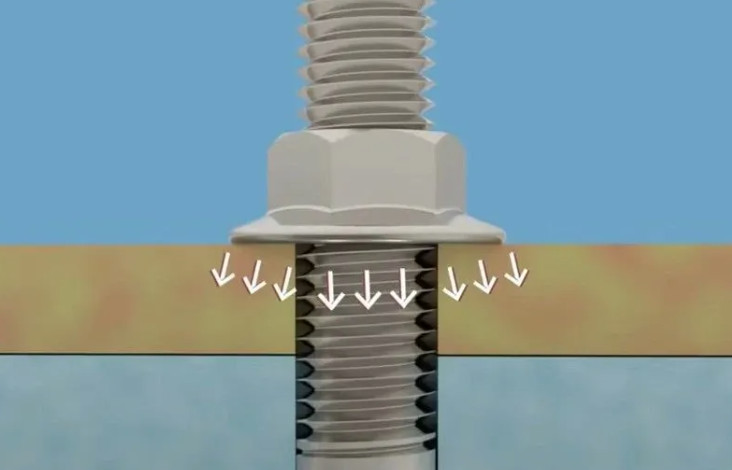

Increase Contact Area, Distribute Pressure

The flange—typically larger in diameter than the hex—substantially enlarges the contact area with the workpiece. By the pressure relation P = F / S, for the same force F, a larger contact area S lowers the pressure per unit area P. Much like pushing a door with your palm instead of a fingertip, the flange spreads load more evenly, reducing local damage and elevating overall compressive performance.

Higher Friction, Greater Stability

The flange face often integrates anti-slip serrations and, in some designs, elastic sealing elements. Once tightened, the serrations micro-embed into the surface to create a mechanical interlock, while a compressed rubber washer provides reactive support through elastic deformation. Working together, they raise the static friction at the interface—akin to tire tread improving grip—dispersing multi-directional stress and absorbing energy. This suppresses self-loosening under vibration and helps maintain a stable pressure distribution, improving both shear resistance and fatigue life.

Integrated Sealing, Longer Service Life

Some flange nuts with elastic seals provide dynamic sealing. Under axial preload, the polymer gasket on the flange undergoes controlled plastic deformation to form multi-stage sealing. By blocking both interface leakage and pressure-driven ingress, it creates a barrier against corrosive media. Test data indicate that, in salt-spray environments, such sealing can reduce the electrochemical corrosion rate of the thread pair by over 80%. By preserving oxide films on thread surfaces, it markedly suppresses stress-corrosion cracking, helping the joint retain ≥95% of its original mechanical properties over its service life.

03. Where the Compression Advantage Matters

- Automotive chassis connections: carry vehicle weight and dynamic road loads—flange nuts maintain stable performance.

- Heavy machinery mounts: long-term high loads—better compression and anti-loosening enhance operational safety.

- Large steel structures: joints facing wind, gravity, and mixed external forces—flange-nut stability is crucial.

Conclusion

Through systemic structural design, hex flange nuts outperform standard nuts across three dimensions: pressure distribution, dynamic stability control, and life-cycle durability. These are the core reasons for their markedly superior resistance to compression.