In precision manufacturing, selecting the appropriate machining process is critical to achieving desired outcomes in terms of accuracy, efficiency, and cost. Two advanced methods, 5-axis machining and Electrical Discharge Machining (EDM), are widely used for complex and high-precision components. This article provides a detailed, technical comparison of these processes, focusing on their principles, applications, advantages, limitations, and key parameters. By understanding their differences, manufacturers can make informed decisions for specific project requirements.

Overview of 5-Axis Machining

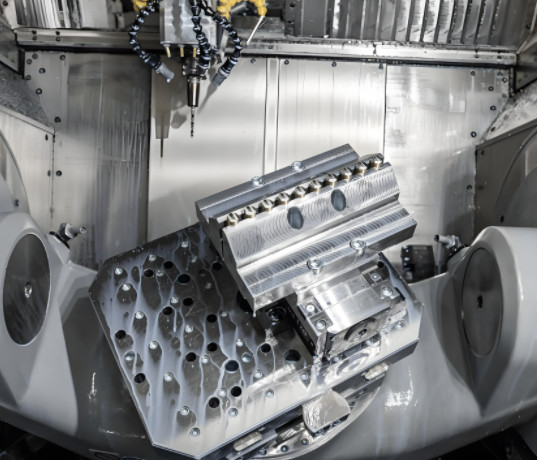

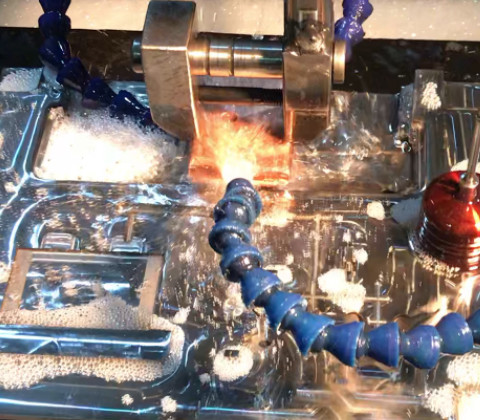

5-axis machining refers to a CNC (Computer Numerical Control) process where the cutting tool moves along five different axes simultaneously. These include three linear axes (X, Y, Z) and two rotational axes (typically A and B, or A and C). This allows the tool to approach the workpiece from virtually any angle, enabling the machining of complex geometries in a single setup.

The process is executed on 5-axis CNC machining centers, which are equipped with a spindle and a worktable capable of tilting or rotating. The key configurations include:

- Double Rotary Table: The workpiece is mounted on a table that rotates along two axes.

- Rotary Table with Swivel Head: Combines a rotating table with a tilting spindle head.

- Double Swivel Head: Both the spindle and workpiece can tilt, offering maximum flexibility.

5-axis machining is widely used in industries such as aerospace, automotive, medical, and mold-making, where complex parts like turbine blades, impellers, and intricate molds are required. The ability to machine multiple surfaces in one setup reduces setup time and improves accuracy.

Technical Parameters:

- Positional Accuracy: Typically within ±0.005 mm to ±0.01 mm, depending on machine quality.

- Surface Finish: Ra 0.4–1.6 µm, achievable with high-speed spindles (10,000–30,000 RPM).

- Maximum Workpiece Size: Up to 1,000 mm x 1,000 mm x 800 mm for standard machines, larger for specialized setups.

- Tool Length: Short tools (20–100 mm) are preferred to minimize deflection and vibration.

Overview of EDM Machining

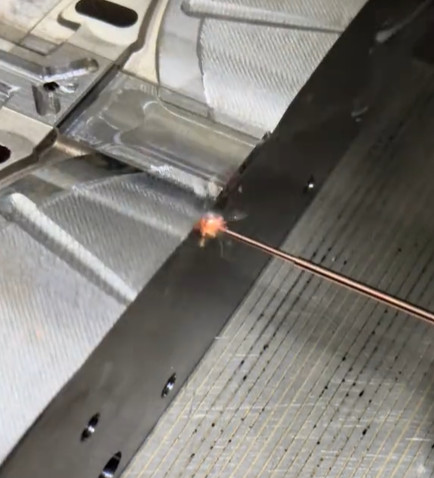

Electrical Discharge Machining (EDM) is a non-traditional machining process that uses electrical sparks to remove material from a conductive workpiece. The process involves a tool electrode and a workpiece submerged in a dielectric fluid (e.g., deionized water or oil). High-voltage pulses generate sparks that erode material through localized melting and vaporization.

EDM is categorized into three main types:

- Sinker EDM: Uses a shaped electrode to create cavities or complex shapes.

- Wire EDM: Employs a thin wire (0.1–0.3 mm diameter) to cut intricate profiles.

- Hole-Drilling EDM: Drills small, deep holes (0.065–3 mm diameter) in hard materials.

EDM is ideal for machining high-hardness materials like tool steel, titanium, or Inconel, commonly used in mold-making, aerospace, and medical device manufacturing. It excels in producing fine details and sharp internal corners that are challenging for traditional machining.

Technical Parameters:

- Accuracy: ±0.002–0.005 mm for wire EDM; ±0.01 mm for sinker EDM.

- Surface Finish: Ra 0.1–0.8 µm, with finer finishes in finishing passes.

- Material Removal Rate: 0.1–10 mm³/min for sinker EDM; 100–300 mm²/min for wire EDM.

- Electrode Wear: 0.1–1% of material removed, depending on settings.

Key Differences in Operating Principles

The fundamental difference between 5-axis machining and EDM lies in their material removal mechanisms. 5-axis machining is a subtractive process that physically cuts material using a rotating tool, relying on mechanical force. EDM, conversely, uses thermal energy from electrical sparks to erode material, making it a non-contact process.

In 5-axis machining, the tool’s path is controlled by precise CNC programming, allowing simultaneous movement across multiple axes. This enables the machining of complex geometries with high efficiency. EDM, however, relies on controlled electrical discharges, with the electrode’s shape or wire path determining the final geometry. The process is slower but excels in hard materials and intricate details.

Comparison Table of Operating Principles:

| Aspect | 5-Axis Machining | EDM Machining |

|---|---|---|

| Material Removal | Mechanical cutting with rotating tools | Thermal erosion via electrical sparks |

| Contact | Contact-based | Non-contact |

| Tool | End mills, drills (2–20 mm diameter) | Electrodes (shaped or wire, 0.1–3 mm) |

| Speed | High (100–1,000 mm/min feed rate) | Low (0.1–10 mm³/min for sinker EDM) |

Applications and Material Suitability

5-axis machining is versatile, suitable for a wide range of materials, including aluminum, steel, titanium, plastics, and composites. It is preferred for parts requiring complex geometries, such as aerospace components (e.g., turbine blades, structural parts), automotive prototypes, and medical implants. Its ability to machine multiple surfaces in one setup makes it ideal for low-to-medium volume production of intricate parts.

EDM is specialized for conductive materials, particularly high-hardness alloys like tool steel, carbide, and titanium. It is commonly used for mold and die manufacturing, where sharp internal corners or fine details are required. Wire EDM is ideal for cutting intricate profiles, while sinker EDM creates complex cavities. Hole-drilling EDM is used for small, deep holes in aerospace and medical components.

Examples of Applications:

- 5-Axis Machining: Turbine blades, impellers, orthopedic implants, complex molds.

- EDM: Injection mold cavities, extrusion dies, micro-holes in turbine blades.

Advantages of Each Process

5-Axis Machining Advantages:

- High Efficiency: Single-setup machining reduces cycle times by 30–50% compared to 3-axis processes.

- Versatility: Suitable for a wide range of materials and geometries.

- Improved Surface Quality: Short tools and optimal cutting angles achieve Ra 0.4–1.6 µm.

- Reduced Setup Errors: Fewer setups minimize alignment issues, ensuring ±0.005 mm accuracy.

EDM Advantages:

- Hard Material Machining: Effectively processes materials with hardness above 60 HRC.

- High Precision: Achieves tolerances as tight as ±0.002 mm for wire EDM.

- Fine Details: Produces sharp corners and intricate features unattainable by mechanical cutting.

- No Mechanical Stress: Non-contact process avoids tool pressure, reducing workpiece deformation.

Limitations and Considerations

5-Axis Machining Limitations:

- High Equipment Cost: 5-axis machines are expensive, with costs ranging from $200,000 to $1,000,000.

- Programming Complexity: Requires advanced CAM software and skilled operators.

- Vibration Sensitivity: High-speed operations demand rigid machine structures to maintain precision.

- Material Limitations: Less effective for extremely hard materials (>60 HRC) due to tool wear.

EDM Limitations:

- Slow Processing Speed: Material removal rates are significantly lower than mechanical machining.

- Conductive Materials Only: Limited to metals and conductive ceramics.

- Electrode Wear: Requires frequent electrode replacement or compensation, increasing costs.

- Surface Integrity: Heat-affected zones may require post-processing for critical applications.

Comparison of Key Parameters

The following table summarizes critical technical parameters for both processes, aiding in decision-making for specific applications.

| Parameter | 5-Axis Machining | EDM Machining |

|---|---|---|

| Accuracy | ±0.005–0.01 mm | ±0.002–0.01 mm |

| Surface Finish | Ra 0.4–1.6 µm | Ra 0.1–0.8 µm |

| Material Removal Rate | High (100–1,000 cm³/min) | Low (0.1–10 mm³/min for sinker; 100–300 mm²/min for wire) |

| Material Suitability | Metals, plastics, composites | Conductive materials only |

| Setup Time | Low (single setup) | Moderate (electrode preparation) |

Practical Considerations for Process Selection

Choosing between 5-axis machining and EDM depends on project requirements. For complex geometries requiring high efficiency and versatility, 5-axis machining is preferred, especially for materials like aluminum or medium-hardness steels. For example, machining a turbine blade with smooth surfaces and tight tolerances (±0.01 mm) benefits from 5-axis machining’s single-setup capability.

EDM is the better choice for hard materials or intricate details, such as mold cavities with sharp internal corners or micro-holes in titanium components. Its non-contact nature ensures no mechanical stress, making it suitable for delicate or heat-treated parts. However, its slower speed and electrode costs must be weighed against precision needs.

Case Example: A mold for an injection-molded part may use 5-axis machining for roughing and semi-finishing to reduce cycle time, followed by EDM for finishing sharp corners and fine details. This hybrid approach leverages the strengths of both processes.

Conclusion

5-axis machining and EDM are powerful manufacturing processes with distinct strengths. 5-axis machining excels in versatility, speed, and complex geometry machining across various materials. EDM is unmatched for high-hardness materials, fine details, and non-contact processing. By evaluating project requirements—such as material type, geometry complexity, precision, and production volume—manufacturers can select the optimal process or combine them for superior results. Understanding these differences ensures efficient, high-quality production tailored to specific needs.