At Kesu Group, our CNC Swiss Machining Service delivers high-precision micro-components for industries requiring tight tolerances and complex geometries. Utilizing advanced Swiss-designed CNC lathes, we specialize in machining small, intricate parts with diameters ranging from 1.1 mm to 38 mm (0.045" to 1.5"). Our state-of-the-art equipment, including 23 sets of 5-axis CNC Swiss Type Automatic Lathes from brands like Star and Tsugami, ensures cost-effective, high-volume production of slender, delicate, or complex components.

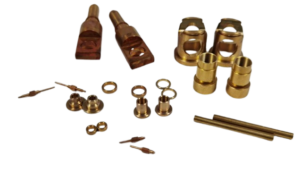

This article explores the definition, techniques, advantages, materials, and applications of CNC Swiss machining, highlighting Kesu Group’s expertise in delivering precision turned parts. Whether you need medical screws, aerospace connectors, or electronic components, our ISO 9001:2008 certified services provide unmatched quality.

What is CNC Swiss Machining?

CNC Swiss machining is a precision manufacturing technique that uses Swiss-designed CNC lathes to produce small, complex, or delicate components with tight tolerances. Originally developed in Switzerland for the watchmaking industry, this process has evolved into a versatile solution for high-volume production of micro-components across various sectors. Kesu Group’s CNC Swiss machining service excels in creating parts with exceptional accuracy, straightness, and concentricity, making it ideal for applications where precision is paramount.

How Swiss Machining Works

Swiss machining operates by feeding bar stock through a guide bushing, which supports the material as it enters the machining area. Only the portion being machined is exposed, ensuring stability and precision. Unlike conventional CNC lathes, where the workpiece is fixed and rotated, Swiss lathes allow the workpiece to move back and forth along the Z-axis while rotating. This enables multiple operations—such as milling, drilling, turning, threading, and boring—to be performed simultaneously, reducing cycle times and enhancing accuracy.

Key Features of Swiss Machining

Kesu Group’s CNC Swiss machining service offers several distinctive features:

- Precision: Achieves tolerances as tight as ±0.001 mm for metal parts and ±0.01 mm for plastics.

- Multi-Axis Capability: 5-axis Swiss lathes enable complex geometries and intricate shapes.

- High Volume Production: Equipped with IEMCA bar feeders, our machines support continuous, automated production.

- Versatility: Handles a wide range of materials, including stainless steel, titanium, PEEK, and more.

Comparison with Conventional CNC Machining

Compared to traditional CNC lathes, Swiss machining offers superior stability for slender parts due to the guide bushing. Conventional lathes hold the workpiece at one or both ends, which can lead to deflection in long, thin parts. Swiss lathes, however, support the material close to the cutting tool, minimizing vibration and achieving tighter tolerances. Additionally, Swiss machines can perform multiple operations simultaneously, reducing production time compared to the sequential operations of standard CNC lathes.

Advantages of CNC Swiss Machining

Kesu Group’s CNC Swiss machining service provides numerous benefits, making it a preferred choice for industries requiring precision micro-components.

Exceptional Precision and Tolerances

Swiss machining is renowned for its ability to hold tolerances as small as ±0.001 mm, making it ideal for applications requiring exact measurements. Kesu Group’s advanced 5-axis Swiss lathes ensure consistent accuracy, even for complex geometries.

High-Speed Production

With cycle times as low as 10 seconds for simple parts, Swiss machining is optimized for high-volume production. Our IEMCA bar feeders enable continuous operation, minimizing downtime and maximizing efficiency.

Complex Geometry Capability

Swiss lathes can produce intricate shapes, including threaded, slotted, or crimped parts, without requiring secondary operations. This versatility allows designers to create complex components with fewer manufacturing steps.

Cost-Effectiveness

By combining multiple operations into a single setup, Swiss machining reduces labor and production costs. Kesu Group’s automated processes further enhance cost savings, particularly for high-volume runs.

Kesu Group’s CNC Swiss Machining Capabilities

Kesu Group is a global leader in CNC Swiss machining, with state-of-the-art facilities and a commitment to quality. Our ISO 9001:2008 certification ensures every component meets stringent industry standards.

Advanced Swiss Machining Equipment

Our CNC Swiss machining workshop is equipped with 23 sets of 5-axis CNC Swiss Type Automatic Lathes, including Star SB 20R Type G and Tsugami BO205-Ⅲ models. Each machine is fitted with an IEMCA bar feeder for continuous production. Below is a table summarizing our Swiss machining equipment:

| Machine | Quantity | Brand | Max Part Size |

|---|---|---|---|

| CNC Swiss Type Automatic Lathe | 13 | Star | D20 x L210 mm |

| CNC Swiss Type Automatic Lathe | 10 | Tsugami | D20 x L210 mm |

Inspection Equipment

Quality control is integral to our CNC Swiss machining process. Our inspection equipment ensures every part meets precise specifications:

| Equipment | Quantity | Brand |

|---|---|---|

| CMM | 2 | LEAD |

| 2.5D | 3 | - |

| XRF Spectrometer | 1 | HITACHI |

| Altimeter | 1 | - |

| Calliper | 20 | - |

| Micrometer | 10 | - |

Tolerance Standards

Kesu Group achieves exceptional precision in CNC Swiss machining. Below are our best tolerance capabilities:

| Feature | Tolerance of Metal (mm) | Tolerance of Plastic (mm) |

|---|---|---|

| Linear Dimensions | ±0.01 | ±0.05 |

| Diameter | ±0.002 | ±0.02 |

| Precise Hole | ±0.002 | ±0.02 |

| Chamfer Heights | ±0.02 | ±0.05 |

| Angular Dimensions | ±0º5′ | ±1º |

| Straightness | ±0.002 | ±0.02 |

| Flatness | ±0.002 | ±0.01 |

| Perpendicularity | ±0.002 | ±0.01 |

| Symmetry | ±0.002 | ±0.01 |

| Concentricity | ±0.002 | ±0.005 |

| Parallelism | ±0.001 | ±0.01 |

Materials for CNC Swiss Machining

Kesu Group supports a wide range of materials for CNC Swiss machining, ensuring compatibility with diverse industry requirements.

Metals

Metals are chosen for their strength, conductivity, and durability. Our offerings include:

- Aluminum: Lightweight with excellent strength-to-weight ratio. Alloys: AL5052-T651, AL6061-T651, AL7075-T651, AL6082-T651.

- Stainless Steel: High strength and corrosion resistance. Alloys: 201, 303, 304, 316, 410, 420, 17-4PH.

- Titanium: High strength-to-weight ratio for aerospace and medical applications. Alloys: Grade 1, Grade 2, Grade 3, Grade 4, Grade 5.

- Copper: Excellent electrical conductivity for electronic components. Alloys: T1, T2, T3, TU1, TU2b.

- Brass: Easy to machine for connectors and fittings. Alloys: H59, H62, HA177-2, HMn58-2, HPb59-1, HSn62-1.

- Bronze: Wear-resistant alloy. Alloy: QSn-6-6-3.

- Magnesium: Low-density alloy for lightweight parts. Alloys: AZ31, AZ41, AZ61.

- Tool Steel: High hardness for durable components. Alloys: A2, D2, D3.

- Zinc: Low melting point for casting applications. Alloys: Z13001, Z15001, Z19001.

Plastics

High-performance plastics offer chemical resistance and low friction for specialized applications:

- PEEK: High thermal and chemical resistance for medical and aerospace parts. Colors: Opaque beige.

- PTFE (Teflon): Low-friction and chemical-resistant for seals and insulators. Colors: Black, White.

- Polycarbonate (PC): Impact-resistant for optical and electronic components. Colors: Clear, Black, Glossy.

- Delrin (POM): Low-friction and high-stiffness for precision parts. Colors: White, Black.

- Nylon: Wear-resistant for connectors. Types: PA6, PA66. Colors: White, Black, others.

Material Selection Guide

Choosing the right material depends on the application’s requirements for strength, conductivity, or chemical resistance. Below is a table summarizing key materials:

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Connectors, housings |

| Stainless Steel | High strength, corrosion-resistant | Medical screws, implants |

| Titanium | High strength-to-weight ratio | Aerospace components, medical devices |

| PEEK | High thermal and chemical resistance | Medical and aerospace parts |

| PTFE | Low-friction, chemical-resistant | Seals, insulators |

Surface Finishes for CNC Swiss Machining

Kesu Group offers a variety of surface finishes to enhance the functionality and aesthetics of Swiss-machined components, ensuring durability and performance.

Oxidation Finishes

Oxidation finishes improve corrosion resistance and durability:

- Anodizing: Applicable to Aluminum for enhanced corrosion resistance.

- Hard Anodized: Applicable to Aluminum for superior wear resistance.

- Micro Arc Oxidation: Applicable to Aluminum, Magnesium, Titanium.

Electroplating Finishes

Electroplating provides protective and conductive layers:

- Nickel Plating: Applicable to Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper.

- Zinc Plating: Applicable to Steel, Stainless Steel, Brass, Bronze for corrosion resistance.

- Black & Zinc: Corrosion-resistant finish for Steel, Stainless Steel, Brass, Bronze.

- Chrome Plating: Applicable to Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper.

- Titanium Coating: Applicable to Stainless Steel for enhanced durability.

Painting and Coating Finishes

Painting and coating options enhance appearance and protection:

- Powder Painting: Applicable to Aluminum, Steel, Stainless Steel, ABS.

- Teflon Coating: Applicable to Aluminum, Steel, Stainless Steel for low friction.

- Painting: Applicable to Aluminum, Steel, Stainless Steel, ABS for aesthetic finishes.

Other Finishes

Additional finishes for specific applications:

- Polishing: Applicable to Aluminum, Stainless Steel, Brass for a smooth finish.

- Sandblasting: Applicable to most materials for a matte texture.

- Passivation: Applicable to Steel, Stainless Steel, Brass for corrosion resistance.

- Laser Marking: Applicable to most materials for branding or identification.

- Silk Screen: Applicable to most materials for detailed graphics.

- Transfer Printing: Applicable to Stainless Steel, coated metals, ABS, PE, PP.

- Blacken/Black Oxide: Applicable to Steel, Stainless Steel for a dark finish.

- DLC Coating: Applicable to Steel for high wear resistance.

- Brushing: Applicable to Aluminum, Stainless Steel, Brass for a linear texture.

Applications of CNC Swiss Machining

Kesu Group’s CNC Swiss machining services support a wide range of industries, delivering precision components for critical applications.

Medical Industry

Swiss machining is ideal for producing medical screws, implants, surgical instruments, and other micro-components. Materials like titanium and PEEK ensure biocompatibility and precision.

Aerospace Industry

High-precision connectors, shafts, and fittings for aerospace applications are manufactured using Swiss machining. Aluminum and titanium provide lightweight, durable solutions.

Electronics Industry

Swiss machining produces contact pins, sockets, and fiber optic connectors for electronic devices. Copper and brass are used for their excellent conductivity.

Other Industries

Our services extend to defense, optical equipment, pharmaceuticals, oil and gas, and food manufacturing, producing parts like firing pins, fluid motion components, and pneumatic parts.

Why Choose Kesu Group for CNC Swiss Machining?

Kesu Group is a trusted partner for CNC Swiss machining, offering unmatched precision and efficiency. Here’s why clients choose us:

- Advanced Facilities: Over 8,000 square meters with 200+ CNC machinings, including 23 Swiss lathes.

- Expert Team: 200+ employees, including 30+ engineers, ensure flawless execution.

- Global Reach: Serving 3,000+ customers with 500,000+ parts produced annually.

- ISO 9001:2008 Certification: Rigorous quality standards for every component.

- Rapid Quoting: Upload drawings to us for instant quotes.

Post-Machining Services

Kesu Group offers a range of post-machining services to enhance the functionality and appearance of Swiss-machined components:

- Anodizing: Improves corrosion resistance for aluminum parts.

- Hardening: Increases durability for metal components.

- Plating: Adds protective or conductive layers like nickel or zinc.

- Laser Etching: Provides permanent marking for identification.

Finished components can be serially numbered, individually bagged, or assembled into kits, with special packaging available upon request.

Frequently Asked Questions (FAQ)

What is CNC Swiss Machining?

CNC Swiss machining is a precision manufacturing process using Swiss-designed CNC lathes to produce small, complex components with tight tolerances, ideal for high-volume production.

What materials are used in CNC Swiss machining?

Kesu Group supports metals (aluminum, stainless steel, titanium, copper) and plastics (PEEK, PTFE, polycarbonate, nylon) for diverse applications.

What tolerances can Kesu achieve with Swiss machining?

We achieve tolerances as tight as ±0.001 mm for metal parts and ±0.01 mm for plastic parts, ensuring precision for micro-components.

Which industries benefit from CNC Swiss machining?

Medical, aerospace, electronics, defense, and optical industries use Swiss machining for components like screws, connectors, and implants.