Complex parts CNC machining is a critical process in modern manufacturing, enabling the production of intricate components with high precision and tight tolerances. These parts, characterized by complex geometries, stringent accuracy requirements, and challenging environmental demands, are essential in industries such as aerospace, automotive, medical, and construction. This guide explores the definition of complex parts, the factors influencing their complexity, the environments they operate in, the equipment required, and the detailed processes involved in their production.

What Are Complex Parts in CNC Machining?

Complex parts are components that demand advanced machining techniques due to their intricate designs, high precision requirements, and unique operational environments. These parts often feature non-standard geometries, tight tolerances, and the need for multiple machining operations, making their production costly and time-consuming. Their low reproducibility and high technical content further distinguish them from simpler components.

Characteristics of Complex Parts

Complex parts are defined by several key attributes:

- Complex Geometry: Intricate shapes, such as curved surfaces, undercuts, or multi-faceted designs, that require advanced machining capabilities.

- High Precision: Tolerances as tight as ±0.01mm, necessitating sophisticated equipment and skilled operators.

- Low Reproducibility: Unique designs that are difficult to replicate without specialized processes.

- High Cost and Time: Multiple operations, setups, and inspections increase production time and expense.

- Environmental Durability: Designed to withstand extreme conditions like high pressure, temperature, or corrosive environments.

Applications of Complex Parts

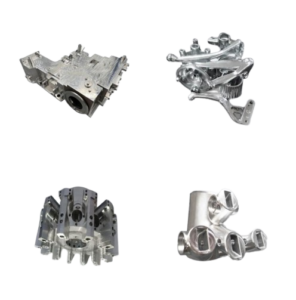

Complex parts are integral to industries where performance and reliability are paramount. Examples include:

- Aerospace: Turbine blades, engine components, and structural parts requiring high precision and durability.

- Automotive: Transmission components and suspension parts with complex geometries.

- Medical: Implants and surgical tools with intricate designs and biocompatible materials.

- Construction: Heavy-duty rollers and hydraulic components for extreme environmental stresses.

Factors Affecting the Complexity of CNC Machined Parts

Several factors contribute to the complexity of CNC machined parts, influencing the machining process, equipment selection, and overall cost. Understanding these factors is crucial for optimizing production and ensuring quality.

Size and Weight of Parts

While size alone does not determine complexity, it significantly impacts machining considerations. Larger parts require robust equipment and larger cutting tools, which can remove material faster but may limit precision for intricate features. Conversely, smaller parts with micro-features demand high-precision tools and controlled environments. For example, a part with a diameter of 500mm and intricate internal features requires a balance between material removal rates and precision, often necessitating multi-axis machines.

Processing Methods

The number of operations, setups, and inspections directly affects part complexity. Complex parts often require multiple machining processes, such as milling, turning, drilling, and grinding, each with specific tooling and setup requirements. For instance, a part with a curved surface and internal threads may need:

- 5-axis milling for the curved surface.

- CNC turning for cylindrical features.

- Threading operations for internal threads.

- Multiple repositionings to access all features.

Each setup increases the risk of errors, making automation and advanced machine capabilities critical for efficiency.

Precision and Tolerances

Tight tolerances, such as ±0.01mm, are a hallmark of complex parts. Achieving such precision requires:

- High-Precision Equipment: 5-axis CNC machines with advanced control systems.

- Specialized Tooling: Carbide or ceramic-coated tools for cutting hardened materials.

- Controlled Environments: Temperature and vibration control to minimize thermal expansion and machining errors.

Tighter tolerances increase costs due to additional processes, slower machining speeds, and the need for rigorous quality checks. For example, aerospace components often require tolerances of ±0.005mm, necessitating multiple inspection stages using coordinate measuring machines (CMMs).

Material Selection

The material of a part influences its machinability and complexity. Common materials for complex parts include:

- Aluminum (6061, 7075): Lightweight, corrosion-resistant, and machinable, ideal for aerospace and automotive parts.

- Stainless Steel (304, 316): Durable and corrosion-resistant, used in medical and industrial applications.

- Titanium (TC4): High strength-to-weight ratio, used in aerospace and medical implants, but difficult to machine.

- Plastics (POM, PTFE): Used for lightweight, non-conductive components, requiring special handling to avoid deformation.

Harder materials like titanium require slower cutting speeds and specialized tools, increasing machining time and cost.

Environmental Requirements for Complex Parts

Complex parts are often designed to operate in extreme environments, such as high-pressure systems, high-temperature engines, or corrosive chemical plants. Their complexity stems from the need to maintain performance under these conditions, requiring advanced materials and machining techniques.

High-Pressure and High-Temperature Environments

Components like turbine blades or hydraulic pistons must withstand pressures exceeding 100 MPa and temperatures above 1000°C. These parts require:

- Heat-Resistant Materials: Nickel-based alloys or ceramics.

- Surface Treatments: Thermal barrier coatings or anodizing to enhance durability.

- Precision Machining: Tight tolerances to ensure leak-proof seals and structural integrity.

For example, a turbine blade may require 5-axis machining to create complex cooling channels, followed by surface treatments to resist thermal fatigue.

Corrosive and Extreme Conditions

Parts in marine or chemical processing environments must resist corrosion and wear. Stainless steel or titanium parts with polished surfaces or protective coatings are common. Machining these parts involves:

- Specialized Tooling: Tools designed to handle high-strength materials without excessive wear.

- Cleanroom Conditions: To prevent contamination during machining and assembly.

An example is a marine propeller shaft, which requires precise machining to ensure balance and corrosion-resistant coatings to withstand saltwater exposure.

Equipment for Machining Complex Parts

Advanced CNC equipment is essential for machining complex parts, with multi-axis machines playing a central role. These machines offer the flexibility and precision needed to produce intricate geometries with minimal setups.

5-Axis CNC Machining Centers

5-axis CNC machines are the gold standard for complex parts, allowing simultaneous movement in five degrees of freedom (x, y, z, A, B, or C). Key features include:

- Multi-Axis Capability: Enables machining of complex surfaces without repositioning.

- High Precision: Tolerances as tight as ±0.005mm.

- Reduced Setups: Minimizes errors and improves efficiency.

Technical specifications of a typical 5-axis CNC machine include:

- Spindle Speed: 10,000–20,000 RPM.

- Table Size: 500mm x 500mm to 2000mm x 1000mm.

- Tool Magazine Capacity: 20–60 tools.

- Control System: Fanuc, Siemens, or Heidenhain.

These machines excel at producing parts like impellers, aerospace brackets, and medical implants with complex contours.

Other Essential Equipment

In addition to 5-axis machines, complex parts machining may require:

- CNC Turning Centers: For cylindrical features and threading.

- Grinding Machines: For achieving high surface finishes (Ra 0.2μm or better).

- CMMs: For precise inspection of tolerances and geometries.

Support equipment, such as tool presetters and coolant systems, enhances machining accuracy and tool life.

Key Considerations in CNC Machining of Complex Parts

Successful machining of complex parts requires careful planning and execution. The following considerations ensure quality, efficiency, and cost-effectiveness.

Machine Cutting Axes

The number of cutting axes determines the machine’s ability to handle complex geometries. A 5-axis machine can access multiple sides of a part in a single setup, reducing errors and lead times. For example, a part requiring machining on five surfaces would need multiple setups on a 3-axis machine, increasing the risk of misalignment.

Tooling and Part Features

Tool selection is critical for complex parts. Standard tools reduce costs, but complex geometries may require custom tools. Key considerations include:

- Tool Material: Carbide or ceramic-coated tools for hardened materials.

- Tool Size: Smaller tools for intricate features, larger tools for rapid material removal.

- Tool Path Optimization: CAM software to generate efficient tool paths.

For instance, machining a part with deep cavities requires long-reach tools, which may reduce cutting speeds to avoid vibration.

Tolerance and Surface Finish

Tight tolerances and fine surface finishes increase complexity. Typical requirements include:

- Tolerance: ±0.01mm for standard complex parts, ±0.005mm for aerospace.

- Surface Finish: Ra 0.8μm for functional surfaces, Ra 0.2μm for polished components.

Achieving these specifications may involve additional processes like grinding or polishing, adding to production time.

Cooperation Process for Complex Parts CNC Machining

The production of complex parts follows a structured process to ensure quality and customer satisfaction. Below is a detailed overview of the cooperation process.

Step-by-Step Process

- Submit Drawings: Clients provide 2D (AutoCAD, DXF, DWG, PDF) or 3D (IGS, STP, PRT) drawings.

- Receive Quotation: A detailed quote is provided based on material, complexity, and tolerances.

- Place Order: Confirm the order and specifications.

- Payment: Secure payment to initiate production.

- Programming: Engineers develop CNC programs using CAM software.

- Production: Machining begins, using CNC milling, turning, or other processes.

- Quality Control: Parts undergo rigorous inspection using CMMs and other tools.

- Packaging: Parts are securely packed to prevent damage.

- Delivery: Parts are shipped to the client’s location.

Machining Capabilities

Supported machining types include:

- CNC Milling: For complex surfaces and multi-faceted parts.

- CNC Turning: For cylindrical and threaded components.

- Grinding: For high-precision surface finishes.

- Additional Processes: Stamping, bending, welding, die casting, drilling, tapping, and injection molding.

Material Options

A wide range of materials is available to meet diverse application needs:

- Aluminum: 6061, 6063, 7075, 5052, 2017, 6083.

- Steel: Q235, 45#, S136, SKD11, 718H.

- Stainless Steel: 303, 304, 316, 430, 420.

- Copper/Brass/Bronze: For conductive and corrosion-resistant parts.

- Titanium: TC4 for high-strength applications.

- Plastics: POM, Teflon, Nylon, PC, PMMA, PEI, PTFE.

Surface Treatments

Surface treatments enhance functionality and aesthetics:

- Anodizing: For corrosion resistance and color options.

- Sandblasting: For uniform surface texture.

- Plating: Chrome, nickel, or zinc for durability.

- Laser Engraving: For logos or part identification.

- Heat Treating: To improve material hardness.

Frequently Asked Questions (FAQ)

What is the difference between 3-axis and 5-axis CNC machining?

3-axis CNC machines move in three linear axes (x, y, z), suitable for simpler parts. 5-axis machines add two rotational axes (A, B, or C), allowing complex geometries to be machined in a single setup, improving efficiency and precision.

What tolerances can be achieved with complex parts CNC machining?

Standard tolerances for complex parts are ±0.01mm, while high-precision applications, such as aerospace, can achieve ±0.005mm with advanced equipment and processes.

Which materials are best for complex parts?

Materials like aluminum (6061, 7075), stainless steel (304, 316), titanium (TC4), and plastics (POM, PTFE) are commonly used, depending on the part’s application and environmental requirements.

How long does it take to machine a complex part?

Lead times vary based on complexity, material, and tolerances but typically range from 1–4 weeks, including programming, machining, and quality control.