Nickel-based alloy impellers are critical components in aerospace and energy systems, valued for their high strength and corrosion resistance. However, machining these materials often introduces residual stresses that can compromise component performance. This article explores the causes of residual stress in impeller machining and provides systematic solutions to mitigate these issues, drawing on established technical knowledge and practical experience.

Understanding Residual Stress in Nickel-Based Alloy Machining

Residual stresses are internal stresses that remain in a material after the external forces causing them, such as machining, are removed. In nickel-based alloys like Inconel 718, these stresses are particularly significant due to the material’s unique properties, including high strength, low thermal conductivity, and rapid work hardening. Residual stresses can be tensile or compressive, with tensile stresses often being more detrimental as they may lead to fatigue failure or crack initiation.

In impeller machining, residual stresses arise from mechanical and thermal interactions during cutting processes. These stresses can affect dimensional accuracy, surface integrity, and the fatigue life of the component, making their control a priority in manufacturing.

Causes of Residual Stress in Impeller Machining

The generation of residual stress in nickel-based alloy impeller machining is influenced by multiple factors related to material properties, machining parameters, and tool characteristics. Below are the primary causes, explained in detail.

Material Properties of Nickel-Based Alloys

Nickel-based alloys, such as Inconel 718, exhibit high strength at elevated temperatures, excellent corrosion resistance, and low thermal conductivity. However, these properties contribute to poor machinability:

- Low Thermal Conductivity: With a thermal conductivity of approximately 11 W/m·K, Inconel 718 retains heat in the cutting zone, leading to high localized temperatures (up to 1000°C). This thermal gradient induces tensile residual stresses on the machined surface.

- High Strength: The ultimate tensile strength of Inconel 718 can exceed 1400 MPa, resulting in high cutting forces (often double those for carbon steels). These forces cause mechanical deformation and residual stress.

- Work Hardening: Nickel-based alloys harden rapidly during machining, increasing cutting resistance and generating tensile stresses in the surface layer.

Machining Parameters

Cutting parameters, including speed, feed rate, and depth of cut, significantly influence residual stress formation:

- Cutting Speed: Higher cutting speeds (e.g., 60–100 m/min) increase cutting temperatures, promoting tensile residual stresses. Studies show that reducing speed to 30–50 m/min can shift stresses toward compressive.

- Feed Rate: Increasing feed rate (e.g., from 0.1 to 0.3 mm/rev) elevates cutting forces, leading to higher tensile stresses. Lower feed rates (0.05–0.15 mm/rev) are associated with reduced stress magnitudes.

- Depth of Cut: A larger depth of cut (e.g., 1–2 mm) increases material removal volume, amplifying thermal and mechanical loads. Shallower cuts (0.2–0.5 mm) minimize stress induction.

Tool Geometry and Wear

Tool design and condition play a critical role in stress generation:

- Tool Edge Radius: A larger edge radius (e.g., 0.05–0.1 mm) increases plowing effects, raising cutting forces and tensile stresses. Smaller radii (0.02–0.04 mm) reduce these effects.

- Rake Angle: Negative rake angles increase cutting forces, while positive rake angles (5–15°) facilitate smoother cutting and lower stresses.

- Tool Wear: Worn tools with flank wear (e.g., VB > 0.3 mm) generate higher friction and heat, exacerbating tensile stresses. Regular tool replacement or coated tools (e.g., TiAlN) mitigates this issue.

Cooling and Lubrication

Inadequate cooling amplifies thermal effects:

- Dry Machining: Without coolant, cutting temperatures soar, leading to tensile stresses exceeding 1000 MPa.

- Conventional Flood Cooling: While effective, it may not penetrate the cutting zone adequately, resulting in residual stresses of 300–600 MPa.

- Spindle Angle: In ball-end milling, increasing spindle angles (e.g., 15–30°) can shift stress distribution toward tensile due to altered chip formation.

Solutions to Mitigate Residual Stress

Controlling residual stress requires a systematic approach, combining optimized machining parameters, advanced tooling, and post-processing techniques. The following solutions are practical and grounded in technical experience.

Optimizing Machining Parameters

Adjusting cutting parameters is a primary method for stress control. Recommended parameters for machining Inconel 718 impellers are summarized in the table below:

| Parameter | Recommended Range | Effect on Residual Stress |

|---|---|---|

| Cutting Speed | 30–50 m/min | Reduces thermal load, shifts stress to compressive |

| Feed Rate | 0.05–0.15 mm/rev | Lowers cutting forces, minimizes tensile stress |

| Depth of Cut | 0.2–0.5 mm | Decreases material deformation, reduces stress |

These parameters balance productivity and surface integrity, minimizing tensile stresses while maintaining acceptable material removal rates.

Advanced Tooling and Coatings

Tool selection and maintenance are critical for stress reduction:

- Coated Tools: TiAlN or TiCN coatings reduce friction and wear, lowering cutting temperatures by 10–20%. These coatings extend tool life and promote compressive stresses.

- Sharp Tools: Maintaining edge sharpness (radius < 0.04 mm) minimizes plowing and heat generation.

- Positive Rake Angles: Tools with 5–15° rake angles reduce cutting forces by up to 15%, decreasing stress induction.

Enhanced Cooling Strategies

Effective cooling reduces thermal gradients:

- High-Pressure Coolant: Applying coolant at 70–100 bar improves penetration into the cutting zone, reducing temperatures by 30–40% and tensile stresses by 20–50%.

- Cryogenic Cooling: Using liquid nitrogen at -196°C induces compressive stresses (up to -500 MPa) by counteracting thermal expansion.

- Minimum Quantity Lubrication (MQL): MQL with vegetable-based oils reduces friction and heat, lowering stresses to 100–300 MPa compared to dry machining.

Post-Processing Techniques

Post-machining treatments can relieve or redistribute residual stresses:

- Heat Treatment: Solution heat treatment at 960°C for 1 hour, followed by aging at 720°C for 8 hours, reduces stresses by 70–90%. For example, Inconel 718 exhibits stress relaxation primarily during heating to the aging temperature.

- Shot Peening: Applying shot peening with 0.2–0.4 mm steel shots at 4–6 A intensity induces compressive stresses up to -1000 MPa, counteracting tensile stresses.

- Laser Shock Peening: This method introduces deep compressive stresses (up to 1 mm depth), improving fatigue life by 20–50%.

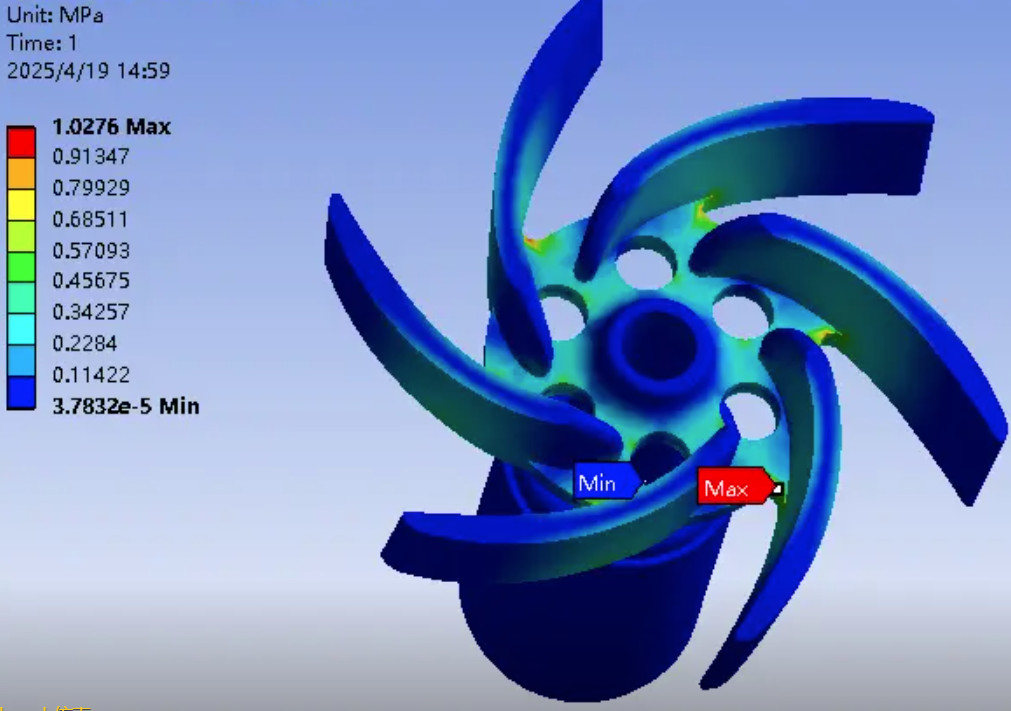

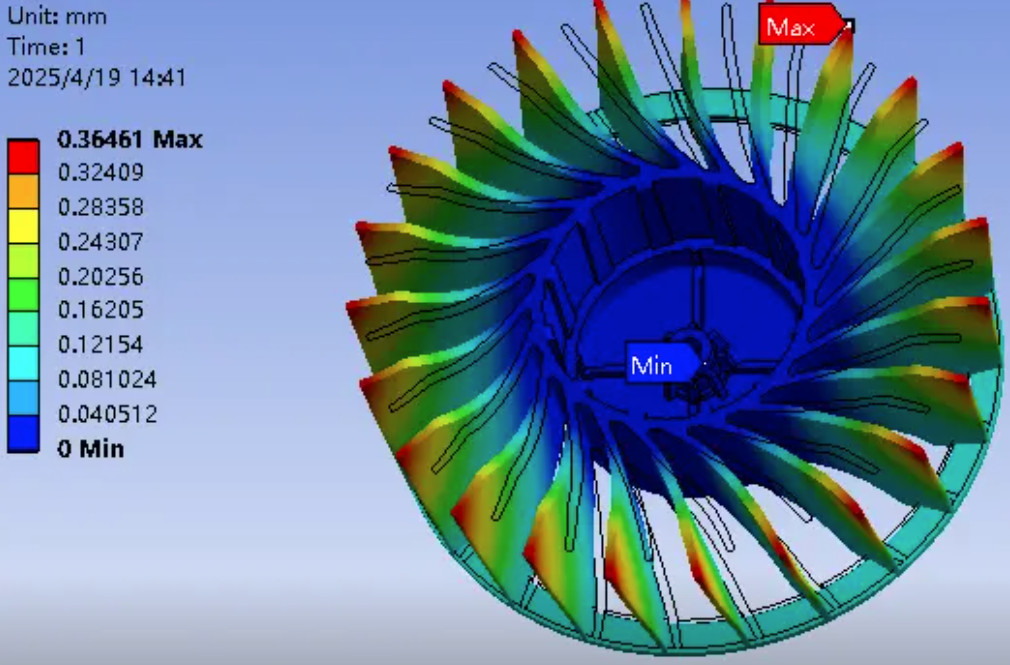

Finite Element Modeling and Process Planning

Finite element (FE) simulations predict residual stress distribution, enabling process optimization:

- Simulation Tools: Software like ABAQUS models stress fields based on cutting parameters, tool geometry, and material properties.

- Multi-Pass Strategies: Dividing machining into roughing (depth of cut 1–2 mm) and finishing (0.1–0.3 mm) passes reduces accumulated stresses by 30–40%.

- Tool Path Optimization: Using trochoidal or adaptive tool paths minimizes thermal concentration, reducing stresses by 10–20%.

Practical Implementation Considerations

Implementing these solutions requires careful planning:

- Machine Rigidity: High-rigidity CNC machines (e.g., 5-axis DMG Mori) ensure precise parameter control, reducing stress variability.

- Operator Training: Skilled operators are essential for maintaining tool conditions and adhering to optimized parameters.

- Quality Control: X-ray diffraction or neutron diffraction measures residual stresses, ensuring process consistency.

Conclusion

Residual stresses in nickel-based alloy impeller machining arise from material properties, machining parameters, tool conditions, and cooling strategies. By optimizing cutting parameters, using advanced tooling, applying effective cooling, and employing post-processing techniques, manufacturers can significantly reduce tensile stresses and enhance component performance. A systematic approach, supported by finite element modeling and rigorous quality control, ensures reliable outcomes in aerospace and energy applications.