Stainless steel impellers are critical components in industries such as aerospace, automotive, and energy, where precision, durability, and performance are paramount. Two primary manufacturing methods for these components are Direct Metal Laser Sintering (DMLS), an additive manufacturing technique, and traditional casting, a subtractive or formative process. This article provides a detailed, technical comparison of the precision achievable with these methods, focusing on dimensional accuracy, surface finish, and mechanical properties. The analysis is grounded in empirical data and industry practices to offer a reliable and systematic evaluation for engineers and manufacturers.

Overview of Manufacturing Processes

Understanding the fundamental principles of DMLS and traditional casting is essential for evaluating their precision in producing stainless steel impellers.

Direct Metal Laser Sintering (DMLS)

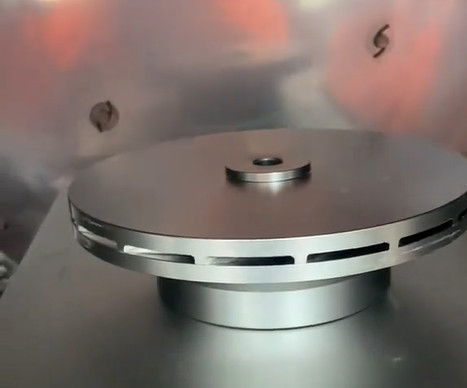

DMLS is a powder bed fusion additive manufacturing process that uses a high-powered laser to selectively fuse fine metal powder particles, typically 20–40 μm in diameter, layer by layer. For stainless steel impellers, common materials include 316L and 17-4 PH stainless steel. The process involves spreading a thin layer of powder on a build platform, scanning the laser to melt the powder according to a digital CAD model, and lowering the platform to add subsequent layers. The result is a near-fully dense part (up to 99.9%) with complex geometries.

Key parameters affecting precision include laser power (200–400 W), scanning speed (500–2000 mm/s), layer thickness (20–50 μm), and powder particle size. DMLS excels in producing intricate features, such as internal cooling channels or thin blades, without the need for tooling or molds.

Traditional Casting

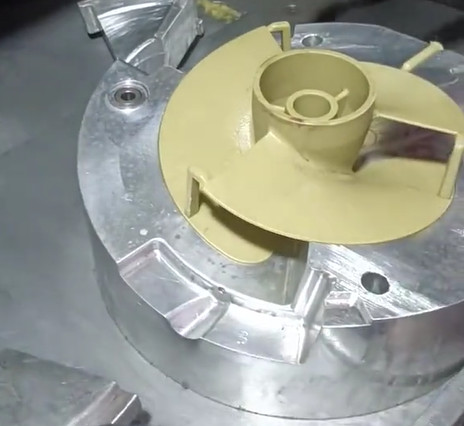

Traditional casting for stainless steel impellers typically involves investment casting or sand casting. Investment casting, more common for precision components, uses a wax pattern coated with a ceramic shell to form a mold. Molten stainless steel is poured into the mold, cooled, and the shell is removed to reveal the part. Sand casting, used for larger or less precise impellers, employs sand molds but offers lower accuracy.

Precision in casting depends on factors such as mold material, pouring temperature (approximately 1500–1600°C for stainless steel), cooling rate, and post-processing. Casting is cost-effective for high-volume production but requires extensive tooling and can introduce defects like shrinkage or porosity.

Dimensional Accuracy

Dimensional accuracy refers to how closely the manufactured impeller matches the intended design specifications, typically measured as tolerance in millimeters or percentages.

DMLS Dimensional Accuracy

DMLS achieves high dimensional accuracy due to its computer-controlled laser and fine layer thickness. Typical tolerances range from ±0.05 mm to ±0.1 mm for features up to 25 mm, with a general accuracy of ±0.3% of nominal dimensions. For stainless steel impellers, critical features like blade thickness (0.5–2 mm) or hub diameters (10–100 mm) can be produced within these tolerances.

However, dimensional accuracy can vary due to thermal shrinkage during cooling, which may cause deviations of up to 2% in the vertical (Z) direction. To mitigate this, manufacturers adjust build orientation and apply post-processing techniques like CNC machining. For example, a 50 mm impeller blade may exhibit a deviation of ±0.075 mm in the X-Y plane and ±0.1 mm in the Z direction after optimization.

Traditional Casting Dimensional Accuracy

Investment casting offers tolerances of ±0.1 mm to ±0.5 mm for features up to 50 mm, while sand casting ranges from ±0.5 mm to ±2 mm. For a stainless steel impeller with a 100 mm diameter, investment casting may achieve a tolerance of ±0.3 mm on the hub, but complex blade profiles can deviate by ±0.5 mm due to mold shrinkage (1–2%) and thermal contraction.

Casting accuracy is limited by mold preparation and material behavior during solidification. Shrinkage cavities or mold misalignment can further reduce precision, requiring secondary machining to meet tight tolerances. For instance, a blade tip may require machining to correct a 0.7 mm deviation caused by uneven cooling.

| Process | Tolerance Range (mm) | Typical Deviation (%) | Post-Processing Requirement |

|---|---|---|---|

| DMLS | ±0.05 to ±0.1 | 0.3% | Minimal (optional CNC) |

| Investment Casting | ±0.1 to ±0.5 | 1–2% | Moderate (machining) |

| Sand Casting | ±0.5 to ±2 | 2–5% | Extensive (machining) |

Surface Finish

Surface finish, measured as surface roughness (Ra), impacts impeller performance, particularly in fluid dynamics and wear resistance.

DMLS Surface Finish

DMLS produces surfaces with an as-built Ra of 8–15 μm for stainless steel impellers, depending on build orientation and laser parameters. Vertical surfaces (parallel to the Z-axis) tend to have higher roughness (Ra 12–15 μm) due to layer stacking, while horizontal surfaces achieve Ra 8–10 μm. For impellers, blade surfaces may require post-processing, such as bead blasting or polishing, to reduce Ra to 1–4 μm for improved aerodynamic performance.

The absence of a heat-affected zone (HAZ) in DMLS minimizes surface defects like cracks or residual stresses, enhancing reliability. However, powder adhesion on downward-facing surfaces can increase roughness, necessitating design optimization to minimize overhangs.

Traditional Casting Surface Finish

Investment casting yields an as-cast Ra of 3.2–6.3 μm, while sand casting produces rougher surfaces (Ra 12.5–25 μm). For impellers, investment casting provides smoother blade surfaces but may exhibit defects like inclusions or surface porosity, requiring sanding or polishing to achieve Ra 1–3 μm. Sand casting, due to its coarse mold material, often demands extensive machining to meet functional requirements.

Casting surface quality is sensitive to mold preparation and pouring conditions. For example, improper mold coating can lead to surface irregularities, increasing post-processing time and cost.

Mechanical Properties

Mechanical properties, including yield strength, tensile strength, and fatigue resistance, determine an impeller’s performance under operational stresses.

DMLS Mechanical Properties

DMLS stainless steel impellers, particularly those made from 316L, exhibit yield strengths of 400–500 MPa and tensile strengths of 500–600 MPa, comparable to or exceeding cast equivalents. The fine microstructure formed during rapid laser melting enhances strength but can introduce anisotropy, with properties varying by build direction. For instance, 316L samples built in the XY-plane show 5–10% higher yield strength than those in the Z-plane.

Fatigue strength in DMLS parts is generally lower than wrought materials due to micro-porosities (0.1–1% volume fraction) but can be improved with Hot Isostatic Pressing (HIP), which increases density to 99.9%. For impellers, this ensures durability in high-cycle applications like pumps or turbines.

Traditional Casting Mechanical Properties

Investment-cast 316L stainless steel impellers have yield strengths of 250–350 MPa and tensile strengths of 450–550 MPa, slightly lower than DMLS parts due to coarser grain structures. Sand-cast impellers may exhibit further reduced properties (yield strength 200–300 MPa) due to porosity and inclusions.

Casting’s mechanical reliability is compromised by defects like shrinkage cavities or gas entrapment, which can reduce fatigue life by 20–30% compared to DMLS parts post-HIP. Heat treatment can mitigate some defects, but casting remains less consistent for critical applications.

Process Limitations and Considerations

While both processes achieve high precision, specific limitations affect their suitability for stainless steel impellers.

DMLS Limitations

DMLS is constrained by build volume (typically 250 x 250 x 300 mm), limiting impeller size. Thermal shrinkage and powder recycling can introduce variability, requiring rigorous process control. Additionally, the high cost of equipment and materials makes DMLS less economical for large production runs.

Traditional Casting Limitations

Casting struggles with complex geometries, such as internal channels, due to mold design constraints. Defect formation, including porosity and shrinkage, necessitates extensive inspection and post-processing, increasing lead times. Tooling costs also make casting less viable for low-volume or custom impellers.

Comparison Summary

| Metric | DMLS | Investment Casting | Sand Casting |

|---|---|---|---|

| Dimensional Tolerance (mm) | ±0.05 to ±0.1 | ±0.1 to ±0.5 | ±0.5 to ±2 |

| Surface Roughness (Ra, μm) | 8–15 (as-built) | 3.2–6.3 (as-cast) | 12.5–25 (as-cast) |

| Yield Strength (MPa) | 400–500 | 250–350 | 200–300 |

| Post-Processing | Minimal | Moderate | Extensive |

DMLS offers superior dimensional accuracy and mechanical properties for stainless steel impellers, particularly for complex designs, but requires careful process control to manage shrinkage. Investment casting provides a balance of precision and cost for medium-volume production, while sand casting is less precise and suited for larger, less critical components. The choice depends on design complexity, production volume, and performance requirements.