Hastelloy, a nickel-based superalloy, is widely used in aerospace, chemical processing, and energy industries due to its exceptional corrosion resistance and high-temperature strength. Manufacturing impellers from Hastelloy presents unique challenges due to the material’s hardness, toughness, and complex geometries. Computer-Aided Manufacturing (CAM) software plays a critical role in generating precise toolpaths for CNC machining of these components. Two leading CAM solutions, Siemens NX (formerly UG) and Autodesk PowerMill, are commonly used for programming such parts. This article provides a detailed, technical comparison of UG and PowerMill programming for Hastelloy impeller manufacturing, focusing on their capabilities, workflows, and practical applications.

Overview of UG (NX) and PowerMill

Siemens NX, often referred to as UG (Unigraphics), is an integrated CAD/CAM/CAE software suite that has been a staple in the manufacturing industry since the 1970s. Its CAM module is renowned for its robust modeling, simulation, and multi-axis machining capabilities, making it a preferred choice for complex components like impellers. NX offers a comprehensive environment where design, toolpath generation, and simulation are seamlessly integrated, particularly for industries like aerospace where precision is paramount.

Autodesk PowerMill, on the other hand, is a dedicated CAM software designed for high-speed and multi-axis CNC machining. Developed initially by Delcam and later acquired by Autodesk, PowerMill excels in generating efficient toolpaths for complex parts, including impellers, blisks, and molds. Its focus on advanced toolpath strategies, collision avoidance, and simulation makes it a go-to solution for manufacturers seeking to optimize machining processes.

Both UG and PowerMill support 3-axis, 3+2, and simultaneous 5-axis machining, which are critical for impeller manufacturing. However, their approaches, user interfaces, and specific strengths differ, impacting their suitability for Hastelloy impeller production.

Material Considerations for Hastelloy Impeller Machining

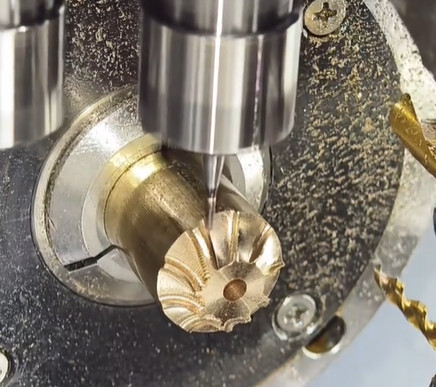

Hastelloy’s high nickel content (e.g., Hastelloy C-276 with 57% Ni, 16% Cr, 16% Mo) results in a material that is difficult to machine. Its properties include a hardness of approximately 20-30 HRC, high tensile strength (up to 790 MPa), and poor thermal conductivity, which leads to heat buildup during machining. These characteristics necessitate specific toolpath strategies to minimize tool wear, ensure surface finish quality (Ra 0.8–1.6 µm for impellers), and maintain dimensional accuracy (tolerances as tight as ±0.01 mm).

Both UG and PowerMill must address these material challenges through optimized roughing and finishing strategies, adaptive toolpaths, and precise control over cutting parameters such as spindle speed (typically 8,000–15,000 RPM for high-speed milling), feed rate (0.05–0.15 mm/tooth), and depth of cut (0.2–1.0 mm for finishing). The software’s ability to handle these parameters effectively is a key differentiator.

Toolpath Generation Capabilities

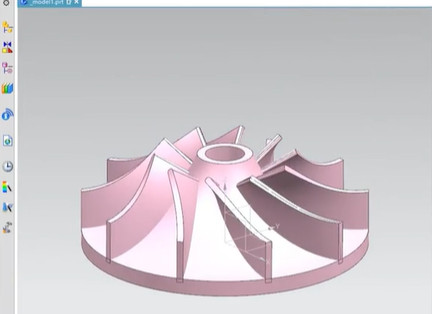

Toolpath generation is the core of CAM programming for Hastelloy impellers, which feature complex, freeform geometries with curved blades and tight internal passages. Both UG and PowerMill offer advanced toolpath strategies, but their approaches and flexibility vary.

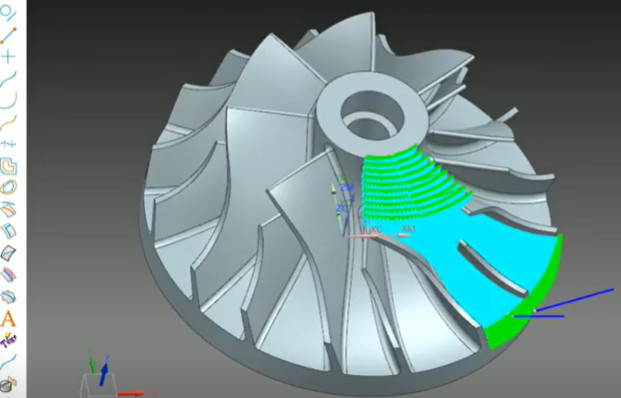

UG (NX) Toolpath Generation: UG provides a robust set of toolpath options, including adaptive clearing, feature-based machining, and multi-axis contouring. Its strength lies in its integrated CAD/CAM environment, which allows users to create and modify impeller geometry within the same software. For example, NX’s impeller machining module includes specialized toolpaths for hub and blade machining, using parameters like step-over (0.1–0.5 mm for finishing) and tool axis control to ensure smooth transitions. UG’s automated feature recognition can identify blade profiles and hub surfaces, streamlining the programming process. Its support for simultaneous 5-axis machining enables precise control over tool orientation, critical for accessing deep, narrow impeller passages.

PowerMill Toolpath Generation: PowerMill is renowned for its extensive library of toolpath strategies, including high-efficiency roughing (e.g., Vortex machining), area clearance, and specialized impeller machining toolpaths. PowerMill’s impeller-specific strategies, such as blade finishing and hub machining, use surface projection and drive surface methods to generate smooth, continuous toolpaths. For instance, its blade finishing toolpath employs a drive surface approach with a step-over of 0.05–0.3 mm and automatic tool-axis smoothing to minimize machine vibration. PowerMill’s high-speed machining capabilities, like trochoidal milling, reduce tool load by maintaining a constant engagement angle (typically 10–20°), which is particularly effective for Hastelloy’s tough material properties.

Comparison: UG excels in scenarios requiring integrated design-to-manufacturing workflows, as its CAD capabilities allow for real-time geometry modifications without file conversions. PowerMill, however, offers superior toolpath optimization for complex 5-axis machining, with a broader range of finishing strategies (over 25 standard options) and faster calculation times due to its 64-bit, multi-threading architecture. For Hastelloy impellers, PowerMill’s specialized impeller toolpaths may provide a slight edge in programming efficiency, while UG’s integrated environment is advantageous for iterative design adjustments.

Simulation and Verification

Simulation and verification are critical to avoid collisions, gouges, and machine over-travel when machining Hastelloy impellers, given the high cost of material (approximately $50–100/kg) and CNC machines (often exceeding $500,000). Both UG and PowerMill offer advanced simulation tools, but their approaches differ.

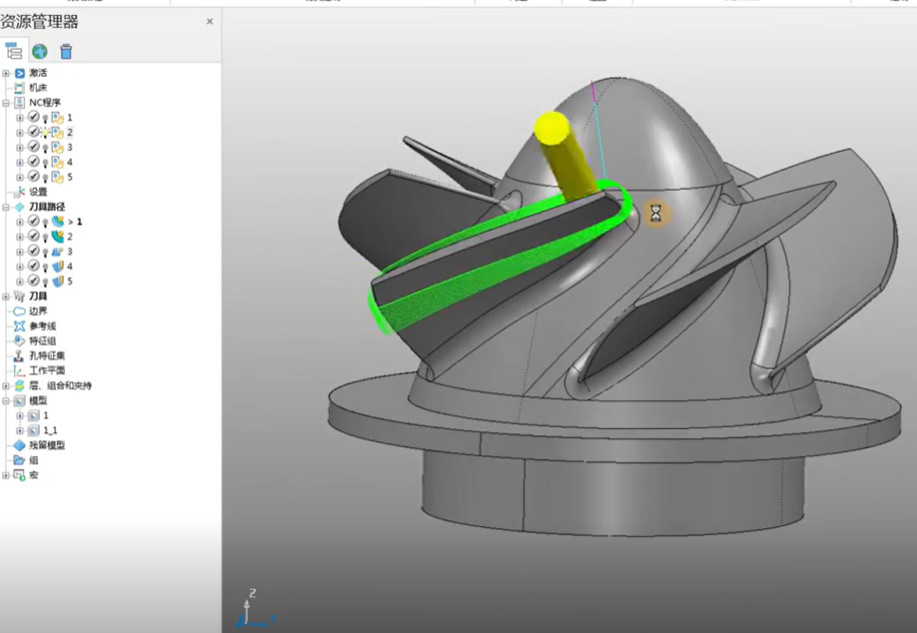

UG (NX) Simulation: UG’s integrated simulation environment uses a 3D model of the CNC machine to simulate toolpaths, detecting collisions and near-misses with high accuracy. Its toolpath verification includes material removal simulation and kinematic analysis, ensuring that the machine’s 5-axis movements align with the programmed paths. For example, UG can simulate a 5-axis mill-turn machine with a spindle speed of 12,000 RPM and verify toolpath safety within a tolerance of 0.01 mm. UG’s simulation is particularly effective for complex setups involving mill-turn operations, common in impeller manufacturing.

PowerMill Simulation: PowerMill’s simulation capabilities are highly regarded for their precision and speed. It uses a virtual 3D model of the CNC machine to simulate toolpaths, with automated collision detection for tools, holders, and workpieces. PowerMill’s stock simulation analyzes unmachined material, identifying areas requiring rest machining with a resolution of 0.05 mm. Its ability to simulate high-rate additive processes (e.g., Directed Energy Deposition) alongside subtractive machining makes it versatile for hybrid manufacturing workflows. PowerMill’s collision avoidance algorithms automatically adjust tool orientation, reducing the risk of errors during 5-axis machining.

Comparison: PowerMill’s simulation is faster and more intuitive, particularly for standalone CAM users, due to its streamlined interface and automated collision avoidance. UG’s simulation, while equally robust, benefits from its integration with the broader NX ecosystem, allowing for seamless transitions between design, programming, and verification. For Hastelloy impellers, PowerMill’s faster simulation times (often 30–50% quicker due to multi-threading) may reduce programming lead times, while UG’s integrated approach minimizes errors in complex, multi-operation setups.

Compatibility and Data Handling

Impeller manufacturing often involves importing CAD models from various platforms, requiring robust data compatibility. Both UG and PowerMill support industry-standard formats like IGES, STEP, and STL, but their handling of data differs.

UG (NX) Compatibility: As part of an integrated CAD/CAM suite, UG excels in handling native NX files and importing third-party CAD data (e.g., CATIA, SolidWorks). Its AnyCAD technology ensures associativity, meaning changes in the CAD model automatically update the toolpaths. This is particularly useful for iterative impeller designs, where blade profiles may be adjusted to optimize performance. UG can handle large, complex models (e.g., 100 MB assemblies) with minimal data loss, though older file formats (e.g., PRO/E 2001) may require conversion to STEP or IGES, potentially introducing minor errors.

PowerMill Compatibility: PowerMill supports a wide range of CAD formats, including Siemens NX, CATIA, and STL meshes, with robust data translation via AnyCAD. Its ability to import and process poor-quality CAD data (e.g., incomplete surfaces or meshes) is a significant advantage for manufacturers working with legacy or third-party models. PowerMill’s data handling is optimized for CAM, with faster import times (typically 10–20% quicker than UG for large files) and automated repair tools for surface gaps up to 0.1 mm.

Comparison: UG’s integrated CAD/CAM environment provides superior associativity and design flexibility, making it ideal for manufacturers who design and machine impellers in-house. PowerMill’s strength lies in its ability to handle diverse CAD inputs and poor-quality data, which is beneficial for job shops or manufacturers collaborating with multiple clients. For Hastelloy impellers, where design iterations are common, UG’s associativity may reduce programming time, while PowerMill’s flexibility suits varied workflows.

Practical Considerations for Hastelloy Impeller Manufacturing

Several practical factors influence the choice between UG and PowerMill for Hastelloy impeller programming, including ease of use, training requirements, and hardware demands.

| Criteria | UG (NX) | PowerMill |

|---|---|---|

| Ease of Use | Steep learning curve due to integrated CAD/CAM/CAE environment; requires familiarity with NX interface. | User-friendly for CAM-focused users; intuitive interface with extensive toolpath templates. |

| Training Requirements | Extensive training (100–200 hours) for full proficiency, especially for CAD integration. | Moderate training (50–100 hours); faster mastery for CAM-specific tasks. |

| Hardware Requirements | High: 16–32 GB RAM, multi-core CPU (e.g., Intel i7), dedicated GPU for large assemblies. | Moderate: 8–16 GB RAM, multi-core CPU; optimized for 64-bit processing. |

| Cost | Higher due to integrated CAD/CAM/CAE licensing; subscription-based pricing. | Lower for standalone CAM; subscription or perpetual licensing available. |

Ease of Use: PowerMill’s CAM-focused interface is more intuitive for programmers solely focused on toolpath generation, with customizable templates and macros reducing setup time. UG’s broader functionality can be overwhelming for new users but offers greater control for those familiar with its ecosystem.

Training Requirements: UG requires more extensive training due to its integrated nature, often necessitating knowledge of both CAD and CAM modules. PowerMill’s streamlined CAM focus allows programmers to achieve proficiency faster, particularly for 5-axis impeller machining.

Hardware Requirements: UG’s comprehensive suite demands robust hardware, especially for large impeller models with millions of polygons. PowerMill’s optimized architecture runs efficiently on mid-range systems, making it more accessible for smaller manufacturers.

Cost: UG’s licensing costs are higher due to its all-in-one CAD/CAM/CAE capabilities, while PowerMill offers a more cost-effective solution for CAM-only users. Manufacturers must weigh these costs against their specific needs for impeller production.

Case Study: Machining a Hastelloy Impeller

Consider a Hastelloy C-276 impeller with a diameter of 300 mm, featuring 12 curved blades and a hub with tight internal passages (minimum clearance of 5 mm). The machining process involves roughing (removing 80% of material), semi-finishing, and finishing to achieve a surface finish of Ra 1.2 µm and tolerances of ±0.02 mm.

UG Workflow: Using NX, the programmer imports the CAD model, defines the blade and hub geometry, and applies adaptive clearing for roughing (depth of cut: 1.5 mm, feed rate: 0.1 mm/tooth). The impeller module generates 5-axis blade finishing toolpaths with a step-over of 0.2 mm and tool axis interpolation to avoid collisions. Simulation verifies the toolpath using a virtual 5-axis DMG MORI machine model, ensuring no gouges. Total programming time: approximately 8 hours, including design adjustments.

PowerMill Workflow: In PowerMill, the programmer imports the same CAD model and uses Vortex roughing (depth of cut: 1.2 mm, engagement angle: 15°) to minimize tool wear. Blade finishing employs a drive surface strategy with a step-over of 0.15 mm and automatic collision avoidance. Simulation is completed in 20% less time than UG due to multi-threading, with stock analysis identifying areas for rest machining. Total programming time: approximately 6 hours.

Outcome: PowerMill completes the programming faster due to its optimized toolpath algorithms and user-friendly interface. UG, however, allows for real-time geometry tweaks, reducing errors in iterative designs. Both achieve the required surface finish and tolerances, but PowerMill’s efficiency may be preferable for high-volume production, while UG suits integrated design-to-manufacturing workflows.

Conclusion

Both UG (NX) and PowerMill are powerful CAM solutions for machining Hastelloy impellers, offering advanced toolpath generation, simulation, and data handling capabilities. UG excels in integrated CAD/CAM environments, providing seamless design-to-manufacturing workflows and robust simulation for complex setups. PowerMill stands out for its speed, extensive toolpath library, and user-friendly interface, making it ideal for standalone CAM tasks and high-efficiency machining. The choice between the two depends on the manufacturer’s priorities: UG for integrated workflows and design flexibility, PowerMill for rapid programming and optimized 5-axis machining. By understanding their strengths and practical considerations, manufacturers can select the software best suited to their Hastelloy impeller production needs.