This guide provides a detailed overview of precision machining, including processes, tools, materials, tolerances, and applications, designed for professionals and beginners seeking technical insights.

What is Precision Machining?

Precision machining is a subtractive manufacturing process that removes material from a workpiece to create parts with tight tolerances and high accuracy. It relies on computer numerical control (CNC) machines to achieve precise dimensions, often within ±0.0002 inches (±0.005 mm). This process is critical for industries requiring components with exact specifications, such as aerospace, automotive, and medical.

The process begins with a digital blueprint, typically created using Computer-Aided Design (CAD) software like AutoCAD or SolidWorks. This design is converted into machine-readable instructions via Computer-Aided Manufacturing (CAM) software, generating G-code and M-code to control CNC machines. Precision machining ensures repeatability, consistency, and minimal waste, making it a cornerstone of modern manufacturing.

Key Processes in Precision Machining

Precision machining encompasses several techniques, each suited to specific part geometries and requirements. Below are the primary processes used in the industry, along with their applications and parameters.

CNC Milling

CNC milling uses rotary cutters to remove material from a workpiece, creating flat surfaces, slots, or complex contours. It is versatile, supporting 3-axis, 4-axis, or 5-axis configurations. Typical tolerances range from ±0.002 inches (±0.051 mm) to ±0.0005 inches (±0.013 mm). Common tools include end mills, face mills, and chamfer mills.

Milling is ideal for producing rectangular or square parts with features like pockets or threads. For example, aerospace brackets or automotive engine blocks often require milling for precise surface finishes, typically Ra 0.8 to Ra 3.2 µm.

CNC Turning

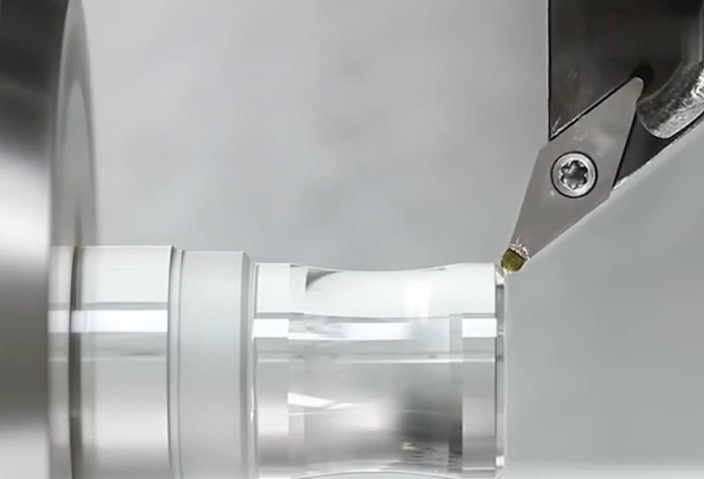

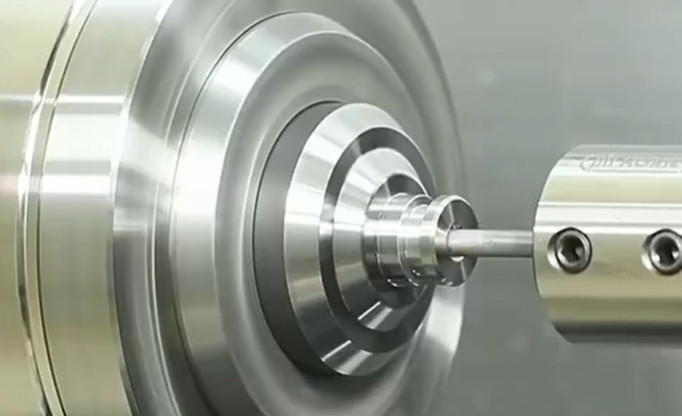

CNC turning rotates the workpiece against a stationary cutting tool to create cylindrical parts like shafts, pins, or bushings. Lathes, such as turret or engine lathes, are commonly used. Tolerances can reach ±0.0002 inches (±0.005 mm), with surface finishes as smooth as Ra 0.4 µm.

Turning is efficient for high-volume production of symmetrical components. For instance, medical implants like bone screws often rely on turning for their precise diameters and threaded features.

Drilling

Drilling creates cylindrical holes using multi-point drill bits. CNC machines ensure accurate hole placement, with tolerances of ±0.005 inches (±0.127 mm) for standard applications and tighter for specialized setups. Drill bits, such as spotting or screw machine drills, are selected based on material and hole depth.

Drilling is often combined with milling or turning, as seen in automotive transmission cases requiring precise bolt holes.

Electrical Discharge Machining (EDM)

EDM uses electrical sparks to erode material, ideal for hard metals like titanium or complex shapes. Wire EDM and sinker EDM are common variants, achieving tolerances of ±0.0001 inches (±0.0025 mm). Surface finishes can reach Ra 0.2 µm, but the process is slower than milling or turning.

EDM is used for intricate molds or aerospace turbine blades where conventional tools are impractical.

Tools and Equipment

Precision machining relies on advanced tools and equipment to achieve desired outcomes. The table below summarizes key equipment, their functions, and typical applications.

| Equipment | Function | Typical Applications | Tolerance Range |

|---|---|---|---|

| CNC Milling Machine | Removes material with rotary cutters | Brackets, engine blocks, molds | ±0.002 to ±0.0005 inches |

| CNC Lathe | Rotates workpiece for cylindrical cuts | Shafts, screws, bushings | ±0.0002 to ±0.005 inches |

| EDM Machine | Uses sparks to erode material | Molds, turbine blades | ±0.0001 to ±0.002 inches |

| Drill Press | Creates precise holes | Bolt holes, mounting points | ±0.005 to ±0.01 inches |

Tool selection is critical. For example, carbide end mills are preferred for high-speed milling of steel, offering durability and heat resistance. Workholding devices, like chucks or vises, ensure stability, minimizing deflection that could compromise precision.

Materials Used in Precision Machining

Precision machining works with a wide range of materials, each chosen based on application requirements. Common materials include:

- Metals: Aluminum (lightweight, machinable), stainless steel (corrosion-resistant), titanium (high strength-to-weight ratio), and bronze (wear-resistant). For example, aluminum 6061 is used for aerospace frames, with a yield strength of 276 MPa.

- Plastics: Delrin (low friction), PEEK (high-temperature resistance), and nylon (durability). PEEK is common in medical devices due to its biocompatibility.

- Composites: Carbon fiber or fiberglass, used in lightweight aerospace components.

Material properties, like hardness or thermal conductivity, influence tool choice and machining parameters. For instance, titanium requires slower cutting speeds (30-50 m/min) to prevent tool wear compared to aluminum (100-300 m/min).

Tolerances and Surface Finishes

Tolerances define the allowable deviation from specified dimensions, typically ranging from ±0.01 mm (±0.0004 inches) for high-precision parts to ±0.1 mm (±0.004 inches) for general applications. Achieving tight tolerances requires specialized setups, such as reaming or grinding, which increase cycle time but ensure accuracy.

Surface finish, measured as roughness average (Ra), affects part performance. For example, hydraulic components require Ra 0.4 µm for smooth fluid flow, while cosmetic parts may tolerate Ra 3.2 µm. Finishing processes like polishing or bead blasting enhance aesthetics or functionality.

Applications of Precision Machining

Precision machining serves diverse industries, producing components with exact specifications. Key applications include:

- Aerospace: Turbine blades, landing gear components, and structural frames, requiring tolerances of ±0.002 mm and materials like titanium or Inconel.

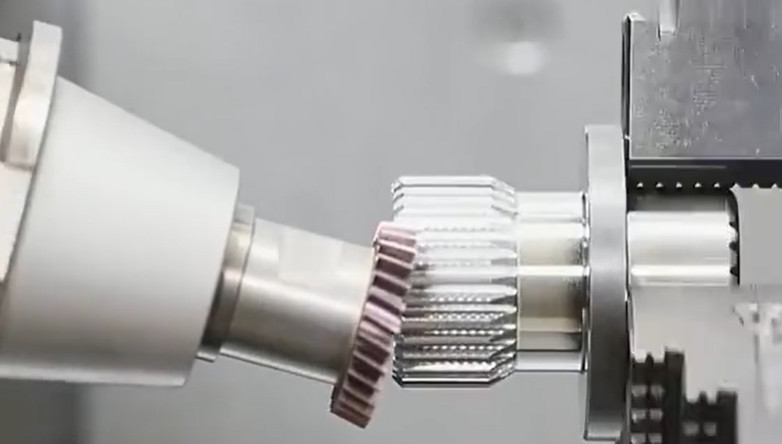

- Automotive: Engine blocks, transmission gears, and fuel injectors, often made from steel or aluminum with Ra 0.8 µm finishes.

- Medical: Implants, surgical instruments, and diagnostic equipment, using biocompatible materials like PEEK or stainless steel 316L.

- Electronics: Heat sinks, connectors, and enclosures, typically aluminum or copper for thermal conductivity.

Each application demands specific parameters, such as hardness (e.g., 40-50 HRC for gears) or corrosion resistance (e.g., for marine propellers).

Key Considerations for Precision Machining

To achieve optimal results, several factors must be addressed during planning and execution:

- Design for Manufacturability (DFM): Simplify geometries to reduce machining time. For example, avoid deep pockets requiring long tools, which risk deflection.

- Tool Maintenance: Regularly inspect and replace worn tools to maintain precision. A dull end mill can increase Ra by 50%.

- Machine Calibration: Ensure CNC machines are calibrated to avoid dimensional errors, typically within 0.001 mm.

- Material Selection: Match material to application needs, balancing cost and performance. For instance, brass is cost-effective for electrical connectors but unsuitable for high-stress parts.

Neglecting these considerations can lead to issues like tool breakage or non-conforming parts, increasing costs and delays.

Quality Control in Precision Machining

Quality control ensures parts meet specifications. Common methods include:

- Coordinate Measuring Machines (CMM): Measure dimensions with accuracy of ±0.001 mm.

- Surface Profilometers: Assess Ra values to verify finish quality.

- Visual Inspection: Detect surface defects like burrs or scratches.

Statistical process control (SPC) monitors production, using data to identify deviations. For example, a control chart tracking hole diameters ensures consistency within ±0.005 mm.

Conclusion

Precision machining is a vital manufacturing process, delivering high-accuracy parts for critical applications. By understanding its processes, tools, materials, tolerances, and quality control, professionals can optimize production outcomes. Whether milling aerospace components or turning medical implants, precision machining combines technology and expertise to meet exacting standards.