Turning machining and Swiss machining are two prominent CNC machining processes used in precision manufacturing. Both methods shape materials by removing material from a rotating workpiece, but they differ significantly in their mechanics, capabilities, and applications. This article provides a comprehensive comparison of conventional turning and Swiss machining, detailing their processes, strengths, limitations, and key considerations for selecting the appropriate method for your manufacturing needs. The focus is on technical accuracy, practical insights, and systematic analysis to guide decision-making in industries such as medical, aerospace, automotive, and electronics.

Overview of Turning Machining

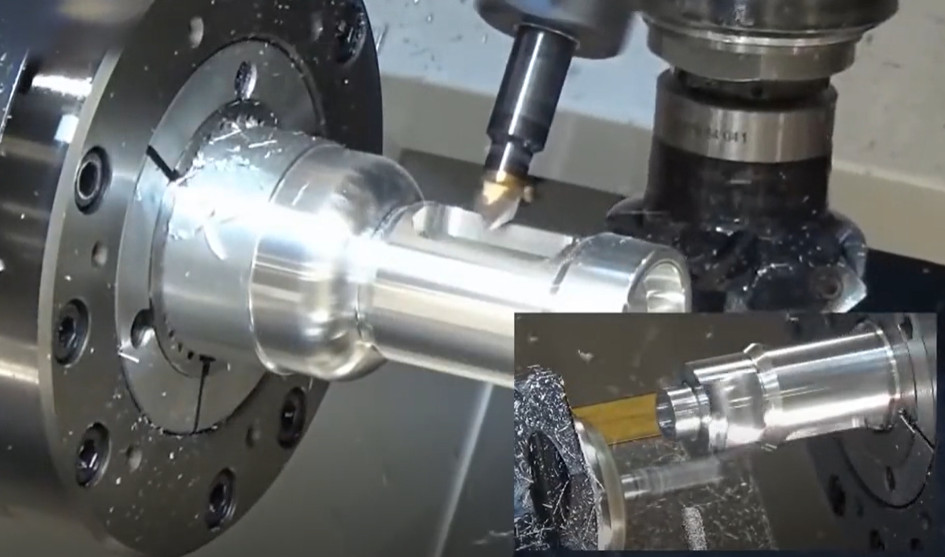

Conventional turning machining is a subtractive manufacturing process performed on a CNC lathe. The workpiece is held in a fixed position, typically secured in a collet or chuck, and rotated at high speeds while a stationary cutting tool removes material to create cylindrical parts. Turning is versatile, capable of producing a wide range of part geometries, from simple shafts to complex components with features like grooves, threads, and tapers.

The process is well-suited for short, large-diameter parts or components made from challenging materials like stainless steel, titanium, or Inconel. Conventional lathes typically operate on three axes (X, Y, Z), with some advanced models incorporating live tooling for milling operations. The workpiece is supported at one or both ends, which can lead to deflection in longer parts, especially those with a length-to-diameter ratio exceeding 4:1.

Key parameters for turning machining include:

- Spindle Speed: Typically ranges from 100 to 6,000 RPM, depending on material and part size.

- Feed Rate: Varies from 0.05 to 0.5 mm/rev for roughing and 0.01 to 0.1 mm/rev for finishing.

- Depth of Cut: 0.5 to 5 mm for roughing and 0.1 to 1 mm for finishing.

- Tolerances: Achieves tolerances of ±0.01 mm for general applications and ±0.005 mm for high-precision work.

- Materials: Metals (aluminum, steel, brass, titanium), plastics, and composites.

Turning is widely used for producing automotive components, industrial machinery parts, and large fittings due to its ability to handle robust materials and larger part sizes efficiently.

Overview of Swiss Machining

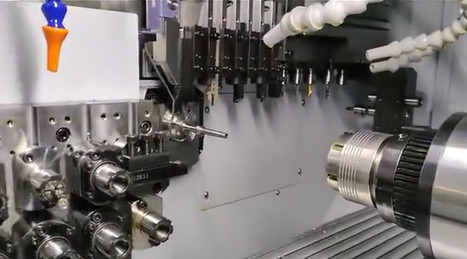

Swiss machining, also known as Swiss turning or Swiss screw machining, is a specialized CNC machining process designed for high-precision, small, and intricate parts. Originating in the 1870s for the Swiss watchmaking industry, this method uses a sliding headstock and guide bushing to feed bar stock through the machine. The guide bushing supports the workpiece close to the cutting tool, typically within 1-2 mm, minimizing deflection and enabling precise machining of long, slender parts.

Swiss lathes often feature multiple axes (up to five or more) and multiple tool stations, allowing simultaneous operations such as turning, milling, drilling, and threading. A secondary spindle can perform back-side operations, reducing cycle times and eliminating the need for secondary setups. Swiss machining excels in high-volume production of complex parts with tight tolerances, often used in medical, aerospace, and electronics industries.

Key parameters for Swiss machining include:

- Spindle Speed: Ranges from 1,000 to 10,000 RPM, optimized for small-diameter parts.

- Feed Rate: Typically 0.02 to 0.3 mm/rev, with finer feeds for micro-machining.

- Depth of Cut: 0.05 to 1 mm, with shallow cuts for precision.

- Tolerances: Achieves tolerances as tight as ±0.0002 mm for micro-machining and ±0.0005 mm for standard applications.

- Materials: Aluminum, stainless steel, titanium, brass, copper, nickel alloys, and rigid plastics like polycarbonate and Teflon.

Swiss machining is ideal for producing components like bone screws, dental implants, aerospace fasteners, and electronic connectors, where precision and repeatability are critical.

Key Differences Between Turning and Swiss Machining

The primary differences between conventional turning and Swiss machining lie in their workpiece handling, precision capabilities, and operational efficiency. The following table summarizes these differences:

| Feature | Conventional Turning | Swiss Machining |

|---|---|---|

| Workpiece Support | Fixed in collet or chuck at one or both ends | Supported by guide bushing near cutting tool |

| Axes of Movement | Typically 3 axes (X, Y, Z) | Up to 5 or more axes |

| Part Size | Suitable for larger diameters (up to 300 mm or more) | Optimized for small diameters (0.03 to 32 mm) |

| Tolerance | ±0.005 to ±0.01 mm | ±0.0002 to ±0.0005 mm |

| Cycle Time | Longer for complex parts due to sequential operations | Shorter due to simultaneous multi-tool operations |

| Applications | Automotive, industrial, large fittings | Medical, aerospace, electronics, watchmaking |

Conventional turning is better suited for larger, simpler parts, while Swiss machining excels in producing small, complex components with ultra-tight tolerances. The guide bushing in Swiss machining ensures minimal deflection, making it ideal for parts with high length-to-diameter ratios, such as medical bone screws or aerospace pins.

Applications and Industry Use

Conventional turning is widely used in industries requiring robust, larger components. Examples include:

- Automotive: Crankshafts, camshafts, and transmission components.

- Industrial Machinery: Shafts, pulleys, and large fittings.

- Construction: Bolts, nuts, and heavy-duty connectors.

Swiss machining, on the other hand, is preferred for industries demanding high precision and small part sizes. Applications include:

- Medical: Bone screws, dental implants, and surgical instruments with tolerances as tight as ±0.0001 inches.

- Aerospace: Fuel injector nozzles, sensor housings, and fasteners requiring high strength and precision.

- Electronics: Connectors, pins, and micro-components for circuit boards.

- Watchmaking: Gears, pins, and other intricate components.

The choice of process depends on the industry’s specific requirements, such as part size, complexity, and production volume.

Material Compatibility

Both turning and Swiss machining can process a wide range of materials, but their suitability varies based on part geometry and machining requirements.

Conventional Turning: Excels in machining tougher materials and larger workpieces. Common materials include:

- Metals: Carbon steel, stainless steel, aluminum, titanium, and Inconel.

- Plastics: Acrylic, nylon, and polyethylene.

- Composites: Carbon fiber and fiberglass.

The process is less sensitive to material properties, making it suitable for heavy-duty materials and larger parts.

Swiss Machining: Optimized for small, precise parts and compatible with:

- Metals: Stainless steel, titanium, aluminum, brass, copper, and nickel alloys.

- Plastics: Polycarbonate, Teflon, and other rigid plastics.

Swiss machining is particularly effective for materials requiring high precision, such as titanium for medical implants, due to its ability to maintain stability during machining.

Cost and Efficiency Considerations

Swiss machining equipment is generally more expensive due to its advanced design, multiple axes, and tooling options. Initial setup costs for Swiss lathes can be 20-30% higher than conventional lathes. However, Swiss machining offers significant efficiency advantages for high-volume production of complex parts, often reducing cycle times by 50% or more due to simultaneous multi-tool operations.

Conventional turning is more cost-effective for low to medium production volumes of simpler parts. Its simpler setup and lower equipment costs make it a practical choice for projects with less stringent precision requirements.

The following table compares cost and efficiency factors:

| Factor | Conventional Turning | Swiss Machining |

|---|---|---|

| Equipment Cost | Lower | Higher (20-30% more) |

| Setup Time | Moderate | Longer due to complex tooling |

| Cycle Time | Longer for complex parts | Shorter for high-volume, complex parts |

| Labor Skill | Moderate | High (requires advanced programming skills) |

For large production runs of intricate parts, Swiss machining’s efficiency often offsets its higher initial costs, while conventional turning remains more economical for simpler, larger components.

How to Choose Between Turning and Swiss Machining

Selecting between conventional turning and Swiss machining depends on several key factors:

- Part Size and Geometry: Swiss machining is ideal for small, slender parts (0.03 to 32 mm diameter) with complex geometries and high length-to-diameter ratios. Conventional turning suits larger parts (up to 300 mm or more) with simpler designs.

- Tolerance Requirements: Swiss machining achieves tighter tolerances (±0.0002 mm) compared to conventional turning (±0.005 mm), making it suitable for ultra-precise applications.

- Production Volume: Swiss machining is more efficient for high-volume production due to its multi-tool capabilities and shorter cycle times. Conventional turning is better for low to medium volumes.

- Material Type: Both processes handle a wide range of materials, but Swiss machining excels with delicate or high-precision materials like titanium and rigid plastics.

- Complexity: Swiss machining’s multiple axes and simultaneous operations make it ideal for complex parts requiring milling, drilling, and threading in a single setup. Conventional turning is better for simpler cylindrical parts.

- Budget: Conventional turning has lower equipment and setup costs, while Swiss machining offers long-term savings for high-volume, complex parts.

For example, producing 10,000 bone screws with a diameter of 2 mm and a length-to-diameter ratio of 10:1 would be best suited for Swiss machining due to its precision and efficiency. Conversely, manufacturing 500 large-diameter (100 mm) automotive shafts would likely be more cost-effective with conventional turning.

Practical Considerations

When choosing between these processes, consider the following practical factors:

- Machine Availability: Swiss lathes are specialized and less common than conventional lathes, which may impact lead times if outsourcing is required.

- Operator Expertise: Swiss machining requires highly skilled operators due to its complex programming and setup. Conventional turning is more accessible to operators with moderate CNC experience.

- Material Quality: Swiss machining requires high-quality, ground bar stock (e.g., Screw Machine Quality, SMQ) to ensure precision through the guide bushing. Conventional turning is less sensitive to material quality.

- Secondary Operations: Swiss machining often eliminates secondary operations by completing complex parts in a single cycle, while conventional turning may require additional setups for milling or drilling.

Collaborating with an experienced manufacturer can help align the process with your project’s specific requirements, ensuring optimal quality and cost-efficiency.

Conclusion

Conventional turning and Swiss machining are both powerful CNC machining processes with distinct strengths. Conventional turning is versatile and cost-effective for larger, simpler parts, while Swiss machining excels in producing small, intricate components with ultra-tight tolerances and high efficiency. By evaluating part size, geometry, tolerance requirements, production volume, material type, and budget, manufacturers can make informed decisions to achieve the best results. Understanding the technical capabilities and practical considerations of each process ensures alignment with project goals, delivering high-quality components tailored to specific industry needs.

FAQ: Turning Machining vs. Swiss Machining

What are the primary differences between conventional turning and Swiss machining?

Conventional turning and Swiss machining differ fundamentally in workpiece support and precision capabilities. Conventional turning fixes the workpiece in a collet or chuck, suitable for larger parts (up to 300 mm diameter) with tolerances of ±0.005 to ±0.01 mm. Swiss machining uses a guide bushing to support the workpiece near the cutting tool, enabling ultra-precise machining of small parts (0.03 to 32 mm diameter) with tolerances as tight as ±0.0002 mm. Swiss lathes also feature more axes (up to 5+) for simultaneous operations, reducing cycle times for complex parts.

When should I choose Swiss machining over conventional turning?

Choose Swiss machining for:

Small, intricate parts with high length-to-diameter ratios (e.g., 10:1 or more)

Tight tolerances (±0.0002 to ±0.0005 mm)

High-volume production of complex components

Industries like medical, aerospace, or electronics requiring precision

How does Swiss machining achieve such tight tolerances?

Swiss machining's precision stems from:

Guide bushing support within 1-2 mm of the cutting tool, minimizing workpiece deflection

Multiple axes (up to 5+) for simultaneous operations

Secondary spindle for back-side machining without repositioning

High spindle speeds (1,000 to 10,000 RPM) optimized for small parts

Advanced tooling and programming for micro-machining

What are typical applications for conventional turning?

Conventional turning is ideal for:

Larger components (up to 300 mm diameter)

Simpler geometries like shafts, pulleys, and fittings

Industries such as automotive (crankshafts, transmission parts), industrial machinery, and construction

Materials like stainless steel, titanium, or composites in heavy-duty applications

Is Swiss machining more expensive than conventional turning?

Yes, Swiss machining has higher initial costs due to:

More complex equipment (20-30% costlier than conventional lathes)

Advanced tooling and multi-axis capabilities

Longer setup times for complex part programming

Requirement for high-quality ground bar stock (SMQ)

However, it offers long-term savings for high-volume production by reducing cycle times (often 50% faster) and eliminating secondary operations.

What materials work best for each machining process?

Conventional Turning:

Tough materials: Stainless steel, titanium, Inconel

Larger workpieces: Aluminum, carbon steel, composites

Plastics: Acrylic, nylon, polyethylene

Swiss Machining:

Small, precise parts: Titanium, brass, copper, nickel alloys

Rigid plastics: Polycarbonate, Teflon

Materials requiring stability: Medical-grade stainless steel, aerospace alloys

How do production volumes impact process selection?

Low to medium volumes: Conventional turning is more cost-effective due to lower setup and equipment costs, suitable for simpler parts.

High volumes: Swiss machining shines with its multi-tool capabilities, reducing cycle times and per-part costs for complex components.