Grinding is a critical machining process used to achieve high-precision surface finishes and tight tolerances in various industries, including aerospace, automotive, and tool manufacturing. Surface finish, often measured as surface roughness (Ra), significantly impacts the performance, durability, and aesthetics of machined components. Achieving an optimal surface finish in grinding requires a systematic approach that considers multiple factors, including machine setup, grinding wheel selection, and process parameters. This guide provides a detailed, experience-based exploration of methods to enhance surface finish in grinding, emphasizing technical precision and practical application.

Understanding Surface Roughness in Grinding

Surface roughness refers to the micro-irregularities on a machined surface, typically quantified by parameters such as Ra (arithmetic average roughness), Rz (maximum height of the profile), and Ry (maximum peak-to-valley height). In grinding, the goal is often to achieve Ra values ranging from 0.1 to 0.8 µm, depending on the application. For instance, precision components like bearings may require Ra values as low as 0.05 µm, while less critical surfaces may tolerate higher values. Understanding the factors influencing surface roughness is essential for optimization.

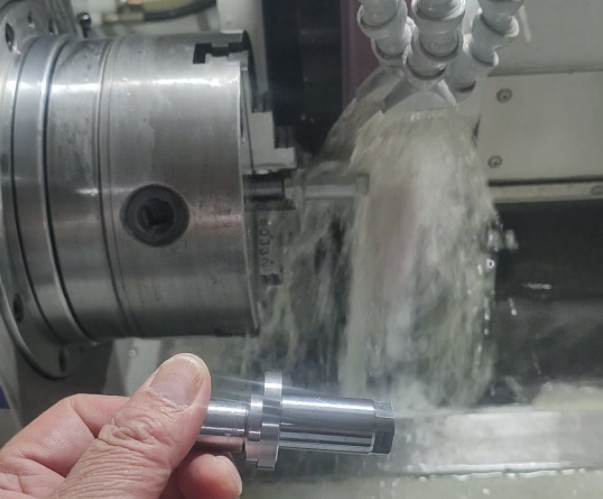

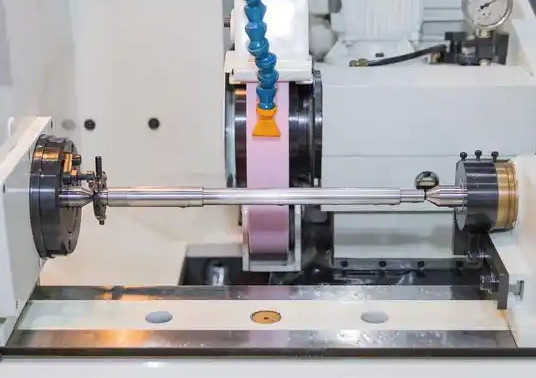

Grinding involves material removal through abrasive particles on a grinding wheel, which interact with the workpiece to create the final surface. The quality of this surface depends on the abrasive type, wheel structure, cutting conditions, and coolant application. By controlling these variables, manufacturers can achieve smoother surfaces and meet stringent specifications.

Key Factors Affecting Surface Finish

Several parameters influence the surface finish in grinding. These include grinding wheel characteristics, machine settings, workpiece material, and environmental conditions. Below is a detailed examination of each factor and how to optimize them for improved surface quality.

Grinding Wheel Selection

The grinding wheel is the primary tool in the grinding process, and its properties directly affect surface finish. Key considerations include abrasive type, grit size, bond type, and wheel structure.

| Parameter | Description | Impact on Surface Finish |

|---|---|---|

| Abrasive Type | Common abrasives include aluminum oxide (Al₂O₃), silicon carbide (SiC), and cubic boron nitride (CBN). | Al₂O₃ is suitable for steels, SiC for non-ferrous materials, and CBN for high-hardness alloys. Choosing the right abrasive minimizes surface damage. |

| Grit Size | Grit sizes range from coarse (e.g., 36) to fine (e.g., 120). | Finer grits (80–120) produce smoother surfaces but may reduce material removal rates. |

| Bond Type | Vitrified, resin, or metal bonds hold abrasives in place. | Vitrified bonds offer precision and are ideal for fine finishes; resin bonds are more flexible for less critical surfaces. |

| Wheel Structure | Refers to the porosity and density of the wheel. | Open structures reduce heat generation, improving finish for heat-sensitive materials. |

For optimal results, select a wheel with fine grit (e.g., 100–120) and a vitrified bond for precision grinding. Regularly dress the wheel to maintain sharpness and prevent glazing, which can degrade surface quality. Dressing with a diamond tool at a depth of 0.01–0.02 mm per pass ensures consistent abrasive exposure.

Cutting Parameters

Cutting parameters, including wheel speed, workpiece speed, depth of cut, and feed rate, significantly influence surface finish. Adjusting these parameters requires balancing productivity and surface quality.

- Wheel Speed: Higher wheel speeds (e.g., 30–40 m/s for conventional grinding) reduce surface roughness by increasing the number of abrasive contacts per unit time. However, excessive speeds may cause thermal damage. For precision grinding, maintain speeds within 25–35 m/s.

- Workpiece Speed: Lower workpiece speeds (e.g., 0.1–0.5 m/min) allow more abrasive interactions, improving finish. For example, reducing workpiece speed from 0.5 m/min to 0.2 m/min can decrease Ra from 0.4 µm to 0.2 µm.

- Depth of Cut: Shallow depths of cut (e.g., 0.005–0.01 mm) minimize surface irregularities. Deep cuts increase material removal but may compromise finish.

- Feed Rate: Lower feed rates (e.g., 0.01–0.05 mm/rev) enhance surface finish by reducing the load on each abrasive grain. A feed rate reduction from 0.1 mm/rev to 0.02 mm/rev can improve Ra by up to 20%.

Experimentation with these parameters is critical. For instance, when grinding hardened steel, a combination of 30 m/s wheel speed, 0.2 m/min workpiece speed, and 0.005 mm depth of cut often yields Ra values below 0.2 µm.

Coolant and Lubrication

Coolant application is vital for controlling heat generation and chip removal, both of which affect surface finish. Effective coolant use reduces thermal damage and prevents chip adhesion to the wheel or workpiece.

- Coolant Type: Water-based emulsions (e.g., 5–10% oil concentration) are effective for most grinding operations. Synthetic coolants offer better heat dissipation for high-speed grinding.

- Flow Rate: A flow rate of 10–20 L/min ensures adequate cooling and chip flushing. Insufficient flow can lead to burn marks and increased roughness.

- Application Method: High-pressure coolant delivery (e.g., 5–10 bar) improves penetration into the grinding zone, reducing friction and heat.

For example, using a high-pressure coolant system at 8 bar with a 5% emulsion can reduce Ra by 15–25% compared to flood cooling at 2 bar. Ensure nozzles are positioned to direct coolant into the contact zone for maximum effectiveness.

Workpiece Material Properties

The material being ground influences surface finish due to its hardness, microstructure, and thermal properties. Hard materials like tool steel (HRC 50–60) require CBN wheels and lower depths of cut to avoid micro-cracks. Softer materials like aluminum benefit from silicon carbide wheels to prevent excessive wheel wear.

Heat-treated materials may develop residual stresses during grinding, affecting surface integrity. To mitigate this, use a stress-relieving pass with a shallow depth of cut (e.g., 0.002 mm) after the main grinding operation. This technique can improve surface finish by up to 10% for high-hardness alloys.

Machine Tool Condition

The condition of the grinding machine, including its rigidity, spindle accuracy, and vibration levels, plays a critical role in surface finish. Regular maintenance ensures optimal performance.

- Spindle Runout: Maintain spindle runout below 0.002 mm to prevent uneven wheel contact, which can increase Ra by 0.1–0.2 µm.

- Machine Rigidity: Ensure the machine bed is stable and free from vibrations. Use vibration-damping mounts if necessary.

- Wheel Balancing: Balance the grinding wheel to within 0.1 g·mm to minimize vibrations, which can degrade surface finish.

Regular calibration and alignment checks, performed every 500–1000 hours of operation, help maintain machine accuracy and consistent surface quality.

Practical Techniques for Surface Finish Optimization

Beyond adjusting parameters, specific techniques can further enhance surface finish. These methods are grounded in practical experience and widely adopted in precision grinding.

Spark-Out Passes

Spark-out passes involve running the grinding wheel over the workpiece without additional depth of cut, allowing the wheel to remove residual material and smooth the surface. Typically, 2–5 spark-out passes at a wheel speed of 25–30 m/s can reduce Ra by 10–20%. For example, a spark-out pass on a cylindrical grinder can improve Ra from 0.3 µm to 0.15 µm.

Wheel Dressing Strategies

Proper wheel dressing maintains abrasive sharpness and wheel geometry, directly impacting surface finish. Use a single-point diamond dresser with a traverse speed of 0.1–0.3 m/min and a dressing depth of 0.01–0.02 mm. For ultra-fine finishes, consider continuous dressing with a rotary diamond dresser, which can maintain Ra below 0.1 µm in precision applications.

Multi-Stage Grinding

Multi-stage grinding involves using progressively finer wheels or parameters to achieve the desired finish. For example, start with a coarse wheel (60 grit) for roughing, followed by a medium wheel (80 grit) for semi-finishing, and finish with a fine wheel (120 grit). This approach ensures efficient material removal while achieving Ra values as low as 0.05 µm.

Common Issues and Solutions

While optimizing surface finish, certain issues may arise. Below is a table summarizing common problems and their solutions.

| Issue | Cause | Solution |

|---|---|---|

| Burn Marks | Excessive heat due to high cutting parameters or inadequate coolant. | Reduce depth of cut to 0.005 mm, increase coolant flow to 15 L/min, and use a high-pressure system. |

| Chatter Marks | Vibrations from unbalanced wheels or machine instability. | Balance the wheel to 0.1 g·mm and check machine rigidity. |

| Wheel Loading | Chip adhesion due to improper wheel selection or coolant. | Use an open-structure wheel and increase coolant concentration to 8%. |

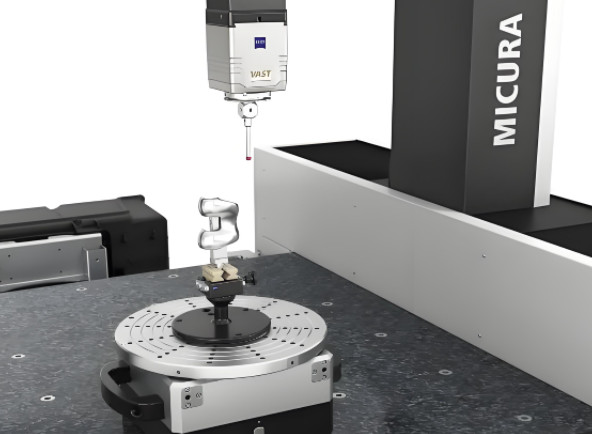

Measurement and Verification

Accurate measurement of surface roughness is essential to verify grinding outcomes. Common tools include stylus-based profilometers, which measure Ra, Rz, and other parameters with high precision. For example, a profilometer with a 2 µm stylus tip can detect roughness variations down to 0.01 µm. Regular calibration of measurement devices ensures reliability.

Non-contact methods, such as laser scanning or optical profilometry, are also effective for delicate surfaces. These methods are particularly useful for verifying finishes below 0.1 µm Ra. Compare measurements against industry standards, such as ISO 4287, to ensure compliance.

Conclusion

Optimizing surface finish in grinding requires a systematic approach that integrates wheel selection, cutting parameters, coolant application, and machine maintenance. By carefully controlling these factors and employing techniques like spark-out passes and multi-stage grinding, manufacturers can achieve Ra values as low as 0.05 µm, meeting the demands of precision applications. Regular monitoring and adjustment, supported by accurate measurement, ensure consistent results. This guide provides a practical, experience-based framework for improving surface finish, grounded in technical expertise and industry best practices.