300M ultra-high-strength alloy steel is a critical material in aerospace manufacturing, particularly for landing gear components, due to its exceptional strength, toughness, and reliability. However, its high hardness and strength pose significant machining challenges, requiring specialized tools, precise parameters, and optimized techniques to ensure stable and efficient production. This guide provides a comprehensive overview of the machining processes for 300M steel, focusing on rough and finish machining, including turning, drilling, and milling. The methods discussed are based on extensive practical experience and are applicable to similar high-strength materials.

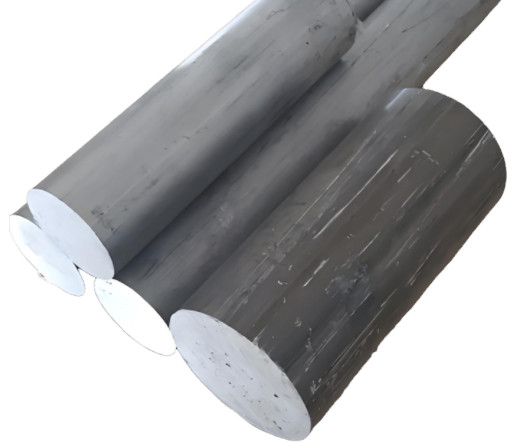

Material Properties of 300M Alloy Steel

300M is a low-alloy, medium-carbon steel containing elements such as nickel, chromium, molybdenum, and vanadium, which contribute to its superior mechanical properties. Its chemical composition and properties make it ideal for high-stress aerospace applications but challenging to machine.

- High Strength: 300M exhibits tensile strength in the range of 1900–2100 MPa, earning its classification as an ultra-high-strength steel.

- High Yield Strength: Compared to non-alloy steels, 300M’s high yield strength allows for 20–30% weight reduction in components under equivalent loads.

- Good Plasticity and Toughness: Despite its strength, the material retains good ductility and toughness due to its low alloy content.

- High Hardenability: Alloying elements like Ni, Cr, and Mo enhance hardenability, enabling martensite and bainite formation through air quenching.

- Heat Treatment States: 300M is typically processed in two heat treatment conditions—normalized and tempered (hardness ~31 HRC) or quenched and tempered (hardness ~52–55 HRC).

The high hardness, strength, and toughness result in significant machining difficulties, including large cutting forces, high cutting temperatures, severe tool wear, and work hardening tendencies. These properties necessitate tailored machining strategies to achieve high-quality results.

Machining Challenges of 300M Alloy Steel

The unique properties of 300M steel create several machining difficulties that must be addressed to ensure efficient and precise production.

- Large Cutting Forces: The high hardness and atomic bonding strength of 300M result in substantial cutting forces, with significant fluctuations during machining.

- High Cutting Temperatures: The material’s high strength leads to significant cutting deformation, generating concentrated heat in the cutting zone.

- Work Hardening: High plasticity and toughness, combined with cutting forces and heat, cause severe plastic deformation, leading to work hardening and the formation of a hard, brittle surface layer.

- Tool Wear: The combination of high cutting forces, elevated temperatures, and material hardness accelerates tool wear through adhesion, diffusion, abrasion, and grooving.

- Chip Management: 300M produces long, ribbon-like chips due to its high strength and ductility, complicating chip removal and posing safety risks.

- Deformation: High cutting temperatures and plasticity can cause thermal deformation, making it difficult to maintain precise dimensions and shapes.

These challenges require careful selection of tools, cutting parameters, and cooling strategies to ensure machining stability and product quality.

Rough Machining of 300M Alloy Steel

Rough machining is typically performed before final heat treatment, when the material is in a normalized and tempered state (~31 HRC). At this stage, the material is relatively soft but sticky, making chip breaking challenging. The goal is to remove as much material as possible to minimize the allowance for finish machining.

Rough Turning

Rough turning is used to shape the external surfaces of 300M components. A commonly used tool is the WIDIA CNMP120408 insert, designed for rough machining due to its robust geometry and chip-breaking capabilities. Recommended cutting parameters are:

- Cutting Speed: 175–200 m/min

- Depth of Cut: 1.5–2.0 mm

- Feed Rate: 0.2–0.4 mm/rev

These parameters ensure high material removal rates while maintaining good chip breaking. The resulting chips are small and manageable, facilitating smooth machining operations.

Deep Hole Machining

Deep hole machining is employed to remove material efficiently, typically using U-drills or deep hole drills, depending on the application.

- U-Drill Machining: Performed on horizontal machining centers due to the high power requirements and larger hole diameters. Cutting parameters include a cutting speed of 40–60 m/min and a feed per tooth of 0.15–0.3 mm. These settings produce thin, well-broken chips, ensuring efficient material removal.

- Deep Hole Drilling: Requires careful chip management to prevent clogging of the drill’s chip evacuation channels. A feed per tooth of 0.2–0.4 mm is recommended, with a preference for 0.3 mm or higher to promote chip breaking. This approach minimizes the risk of long, thin chips clogging the tool, ensuring smooth operation.

Both methods require robust tool designs and adequate cooling to manage heat and chip evacuation effectively.

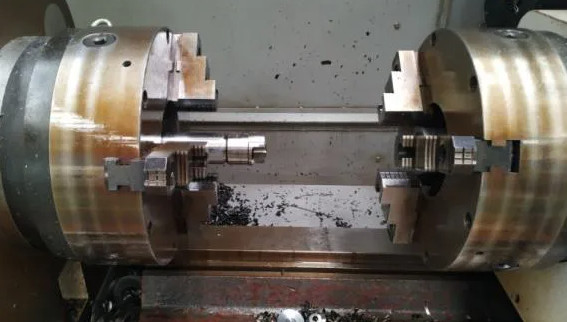

Finish Turning of 300M Alloy Steel

Finish turning, including external turning and internal boring, is performed after final heat treatment (quenched and tempered, ~52–55 HRC). At this stage, the material’s increased hardness and strength amplify machining challenges. Finish turning is divided into rough and finish stages to achieve high precision and surface quality.

External Turning

For external turning, the WIDIA DNMP150604SM insert with a TN6010 coating is recommended. This insert is designed for high-strength alloy steels, featuring a chip-breaking geometry that minimizes material-tool adhesion and ensures smooth chip evacuation. The coating enhances tool life and surface finish.

| Operation | Cutting Speed (m/min) | Depth of Cut (mm) | Feed Rate (mm/rev) |

|---|---|---|---|

| Rough Turning | 90–120 | 0.3–0.8 | 0.1–0.2 |

| Finish Turning | 90–120 | 0.05–0.1 | 0.05–0.1 |

Rough turning uses a single-point contact to reduce cutting forces and heat, while finish turning with smaller depths of cut and feed rates ensures a smooth surface finish. The resulting chips are long and curled due to the material’s high strength and limited chip-breaking ability at this stage.

Internal Boring

Internal boring is more challenging than external turning due to limited tool rigidity, chip evacuation difficulties, and cooling constraints. Key considerations include:

- Adequate Cooling: High-pressure coolant with sufficient concentration is essential to manage heat and lubricate the cutting zone.

- Chip Evacuation: Segmented boring is used, dividing the hole into sections to facilitate chip removal and prevent tool deflection.

- Tool Rigidity: Anti-vibration boring bars with large diameters and lengths slightly longer than the workpiece are used to enhance rigidity and minimize chatter.

Rough boring parameters are similar to rough external turning, while finish boring parameters align with finish turning to achieve high surface quality. Chips from boring are longer and more curled than those from external turning due to the smaller depth of cut and constrained chip evacuation.

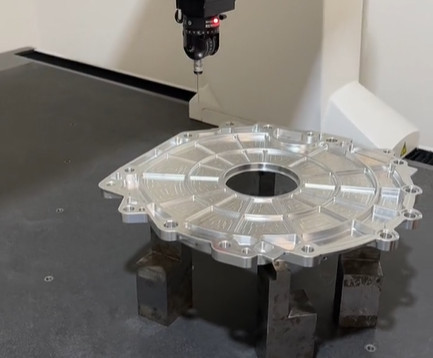

Milling of 300M Alloy Steel

Milling is typically performed as the final machining step to shape external features. The choice of tools and techniques depends on the feature size and precision requirements.

Rough Milling

Rough milling employs indexable tools for high efficiency and cost-effectiveness. The Sandvik R390-020A20-11M tool with R390-11 T3 31M-KM inserts is recommended for its durability and dimensional stability. Cutting parameters are:

- Cutting Speed: 100–150 m/min

- Depth of Cut: 0.5 mm

- Feed Rate: 400–800 mm/min

Excessive depths of cut should be avoided to prevent insert chipping or premature wear. The resulting chips are short and manageable, supporting efficient material removal.

Small Feature Milling

For small features, large-diameter tools are impractical. Cycloidal milling is preferred over layered milling due to its advantages:

- High efficiency and low radial cutting forces

- Reduced sensitivity to vibration

- Minimal deflection in deep slot machining

- Improved chip evacuation and lower heat generation

Cycloidal milling is particularly effective for hard materials like 300M, with cutting speeds of 150–200 m/min, ensuring high productivity and tool life.

Finish Milling

Finish milling requires tools with sharp cutting edges and coatings to achieve the desired surface roughness. Tools are selected to match the feature size closely, ensuring rigidity and precision. The resulting surface quality meets stringent aerospace requirements, with minimal defects.

Quality Control in 300M Machining

Aerospace components operate in harsh environments, making quality control critical. Minor machining defects can lead to significant issues in subsequent processes, such as coating or assembly. To mitigate risks:

- Tool Selection: Use specialized tools designed for high-strength alloys to minimize wear and ensure consistent performance.

- Parameter Optimization: Adhere to recommended cutting parameters to reduce heat, deformation, and tool wear.

- Process Monitoring: Regularly inspect tools, chips, and surface quality to detect and address issues early.

- Cooling and Chip Management: Ensure adequate coolant supply and effective chip evacuation to maintain machining stability.

By implementing these measures, manufacturers can achieve stable, high-quality production of 300M components, minimizing rework and scrap.

Conclusion

Machining 300M ultra-high-strength alloy steel requires a systematic approach, leveraging specialized tools, precise cutting parameters, and robust process controls. Rough machining focuses on efficient material removal using tools like WIDIA CNMP120408 inserts and U-drills, while finish machining employs advanced inserts like WIDIA DNMP150604SM for turning and Sandvik tools for milling. Techniques such as segmented boring and cycloidal milling address specific challenges like chip evacuation and tool rigidity. By adhering to these methods, manufacturers can achieve stable, high-quality production, ensuring the reliability of aerospace components made from 300M steel. These processes are also adaptable to other high-strength alloys, offering broad applicability in advanced manufacturing.