Titanium alloy impellers, widely used in aerospace, power generation, and marine applications, are valued for their high strength-to-weight ratio, excellent corrosion resistance, and ability to perform under extreme conditions. However, high-speed cutting (HSC) of titanium alloys, such as Ti-6Al-4V, generates significant heat, leading to thermal deformation. This deformation compromises dimensional accuracy and surface integrity, particularly in complex, thin-walled impeller structures. This article outlines a systematic, technical approach to address thermal deformation during HSC, focusing on proven methods, detailed parameters, and practical solutions to ensure precision and reliability.

Mechanisms of Thermal Deformation in HSC

Thermal deformation in titanium alloy impellers arises from the heat generated at the tool-workpiece interface during HSC. Titanium alloys have low thermal conductivity (approximately 6.7 W/m·K for Ti-6Al-4V at room temperature), causing heat to concentrate in the cutting zone rather than dissipate. Cutting temperatures can exceed 900°C, leading to thermal expansion, residual stresses, and dimensional deviations. The low elastic modulus of titanium alloys (110–114 GPa) amplifies deformation, especially in thin-walled sections with thicknesses below 2 mm. High cutting speeds (100–200 m/min) and improper tool or cooling strategies exacerbate these effects.

Key contributors to thermal deformation include excessive cutting forces, inadequate heat dissipation, and uneven temperature distribution. Thin-walled impeller blades are particularly susceptible due to their low rigidity and high aspect ratios. Understanding these mechanisms is critical to developing effective mitigation strategies.

Tool Materials and Geometry Optimization

Selecting appropriate tool materials and geometries is fundamental to reducing heat generation and transfer during HSC of titanium alloys. The following considerations enhance thermal management:

- Tool Materials: Polycrystalline diamond (PCD) tools are ideal for HSC due to their exceptional hardness and thermal stability up to 1200°C. Cubic boron nitride (CBN) tools are also effective, maintaining integrity at temperatures above 1000°C. For cost-sensitive applications, carbide tools with coatings like TiAlN or AlCrN provide good performance, reducing heat transfer by 10–15% compared to uncoated tools.

- Tool Geometry: A positive rake angle of 8°–12° reduces cutting forces and heat generation. A nose radius of 0.6–1.0 mm minimizes stress concentration, while a helix angle of 35°–45° improves chip evacuation, lowering heat buildup by approximately 10%. End mills with variable pitch designs further reduce vibration and thermal effects.

- Coatings: Multi-layer coatings, such as TiAlN, reduce friction coefficients to 0.4–0.5, decreasing cutting temperatures by 15%–20%. Diamond-like carbon (DLC) coatings are also effective for high-speed applications.

Tools should be tailored to the impeller’s geometry, with specialized designs for thin-walled sections to minimize heat input and ensure stability.

Optimized Cutting Parameters

Cutting parameters directly influence heat generation and thermal deformation. The following table provides recommended parameters for HSC of titanium alloy impellers, based on empirical data:

| Parameter | Recommended Range | Impact on Thermal Deformation |

|---|---|---|

| Cutting Speed (Vc) | 80–150 m/min | Moderate speeds balance heat generation and chip evacuation. |

| Feed Rate (f) | 0.04–0.12 mm/tooth | Lower feeds reduce heat but increase machining time. |

| Depth of Cut (ap) | 0.3–1.5 mm | Shallow cuts minimize heat input, ideal for thin walls. |

| Cutting Width (ae) | 0.1–0.25 × tool diameter | Reduced width lowers radial forces and heat concentration. |

These parameters should be adjusted based on material grade and impeller design. For example, Ti-6Al-4V requires lower feed rates than Ti-5Al-5Mo-5V-3Cr due to its higher hardness. Using CNC machines with adaptive control systems allows dynamic adjustment of parameters, reducing thermal deformation by up to 25%. Real-time monitoring of cutting forces and temperatures further optimizes parameter settings.

Advanced Cooling and Lubrication Techniques

Effective cooling and lubrication are critical to dissipating heat and minimizing thermal deformation. Titanium’s low thermal conductivity necessitates specialized cooling methods:

- Minimum Quantity Lubrication (MQL): MQL delivers 10–30 ml/h of lubricant, reducing friction and cutting temperatures by 15%–25% compared to dry machining. Vegetable-based oils are preferred for their environmental benefits and cooling efficiency.

- Cryogenic Cooling: Liquid nitrogen (LN2) at -196°C or CO2 at -78°C cools the cutting zone, reducing temperatures by 35%–45%. Cryogenic cooling also improves tool life by 20%–30% and minimizes thermal expansion in thin-walled sections.

- High-Pressure Coolant (HPC): HPC systems at 80–120 bar enhance chip evacuation and reduce cutting temperatures by 20%–30%. This is particularly effective for deep-pocket machining in impellers.

Hybrid cooling, combining MQL and cryogenic methods, can reduce temperatures by up to 50% while maintaining surface integrity. Coolant delivery should be precisely directed to the cutting zone using internal tool channels or high-precision nozzles.

Machining Strategies for Thermal Stability

Strategic machining approaches minimize heat accumulation and ensure dimensional accuracy:

- Trochoidal Milling: Trochoidal tool paths with 5%–8% radial engagement reduce heat input by 10%–15%. This method is ideal for thin-walled impeller blades, maintaining consistent chip loads.

- Multi-Pass Machining: Dividing the process into multiple passes with depths of cut below 1 mm prevents heat buildup. This approach reduces deformation by 15%–20% in high-aspect-ratio features.

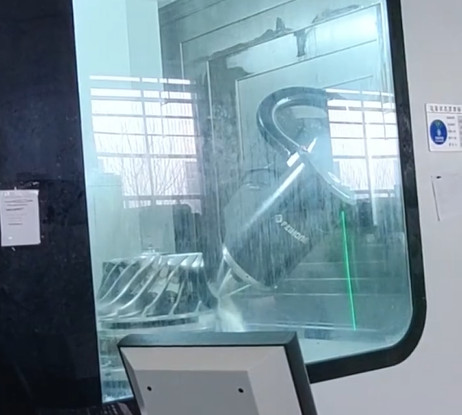

- Five-Axis Machining: Five-axis CNC machines enable continuous tool orientation, reducing contact time and heat transfer. This method can decrease thermal deformation by 20%–30% compared to three-axis machining.

Advanced CAM software, such as Siemens NX, optimizes tool paths to distribute heat evenly, ensuring stability during complex impeller machining.

Fixturing and Workpiece Support

Proper fixturing mitigates vibration and thermal deformation, particularly in thin-walled impellers:

- Modular Fixtures: Modular systems with adjustable clamping forces minimize stress-induced deformation. Clamping pressures should not exceed 2–3 MPa to avoid distortion.

- Vacuum Chucks: Vacuum fixturing provides uniform support, reducing deformation by 10%–15% in complex geometries.

- Damping Supports: Temporary supports or damping materials, such as polymer pads, stabilize thin sections, reducing thermal expansion effects by 5%–10%.

Finite element analysis (FEA) should be used to design fixtures, predicting thermal and mechanical stresses to optimize clamping configurations.

Post-Machining Quality Control

Post-machining processes ensure dimensional accuracy and mitigate residual thermal effects:

- Metrology: Non-contact methods, such as laser scanning or CMM with 0.005 mm accuracy, detect thermal-induced deviations. In-process thermal imaging monitors temperature gradients, enabling corrective actions.

- Stress Relief: Annealing at 550°C–650°C for 1–2 hours reduces residual stresses by 15%–25%, stabilizing dimensions.

- Finish Machining: Light finishing passes with low parameters (Vc = 60–100 m/min, f = 0.03–0.06 mm/tooth) correct minor deformations, achieving tolerances within ±0.01 mm.

Integrating in-line inspection systems ensures real-time quality control, minimizing rework and ensuring compliance with stringent tolerances.

Systematic Integration of Solutions

A comprehensive approach combining the above strategies ensures optimal thermal management. The following table summarizes key solutions and their effectiveness:

| Solution | Key Parameters | Thermal Deformation Reduction |

|---|---|---|

| PCD Tools | Rake angle: 8°–12°, Coating: TiAlN | 10%–15% |

| Cryogenic Cooling | LN2 at -196°C, 10–15 L/min | 35%–45% |

| Trochoidal Milling | Radial engagement: 5%–8% | 10%–15% |

| Five-Axis Machining | Dynamic tool orientation | 20%–30% |

Collaboration between tool manufacturers, machining engineers, and quality control teams is essential to implement these solutions effectively, tailoring them to specific impeller designs and material properties.

Conclusion

Mitigating thermal deformation in high-speed cutting of titanium alloy impellers requires a systematic integration of advanced tooling, optimized cutting parameters, effective cooling, strategic machining, robust fixturing, and rigorous quality control. By applying the technical solutions and parameters outlined, manufacturers can achieve high precision, maintain surface integrity, and meet demanding performance standards in critical applications.