Optimizing CNC machining parameters to achieve an ultra-smooth Ra0.05 surface finish on molecular pump impellers requires precision, expertise, and systematic adjustments. This guide provides detailed technical insights into achieving this high level of surface quality.

Understanding Ra0.05 Surface Finish Requirements

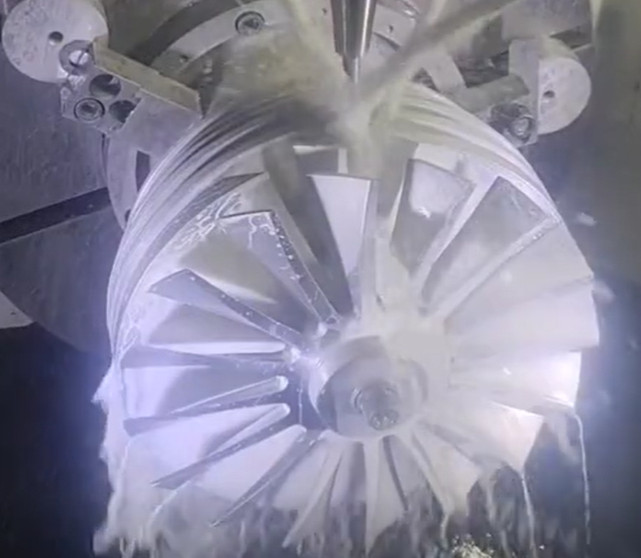

The Ra0.05 surface finish, representing an average surface roughness of 0.05 micrometers, is among the smoothest achievable in CNC machining. For molecular pump impellers, this level of finish is critical due to their high-speed rotation (up to 90,000 RPM) and the need for minimal friction and turbulence in vacuum environments. Achieving Ra0.05 ensures optimal aerodynamic performance, reduces wear, and enhances durability. The process demands meticulous control over machining parameters, tool selection, and post-processing techniques.

Surface roughness is measured as the arithmetic average of the absolute deviations of the surface profile from the mean line. For Ra0.05, the surface must be nearly mirror-like, with no visible machining marks under magnification. This requires a combination of advanced CNC equipment, typically 5-axis machines, and precise parameter settings.

Key CNC Machining Parameters for Ra0.05

Achieving Ra0.05 involves optimizing several CNC machining parameters, including spindle speed, feed rate, depth of cut, tool path strategy, and coolant application. Each parameter must be fine-tuned to minimize vibration, tool wear, and surface imperfections. Below is a detailed breakdown of these parameters.

Spindle Speed

Spindle speed, measured in revolutions per minute (RPM), directly affects surface finish quality. For molecular pump impellers, typically made from aluminum or titanium alloys, high spindle speeds are preferred to reduce cutting forces and improve surface smoothness. A spindle speed range of 20,000 to 30,000 RPM is often used for finishing operations. Higher speeds reduce chip load per tooth, minimizing surface irregularities. However, excessive speeds can cause tool overheating, so coolant or minimum quantity lubrication (MQL) is essential.

For example, when machining a titanium impeller with a 6mm ball-end mill, a spindle speed of 25,000 RPM has been shown to produce a surface roughness close to Ra0.1, which can be further refined to Ra0.05 with polishing.

Feed Rate

Feed rate, or the speed at which the tool advances through the material (mm/min or mm/tooth), is critical for controlling surface finish. A low feed rate reduces the distance between successive tool passes, resulting in a smoother surface. For Ra0.05, a feed rate of 0.01 to 0.03 mm/tooth is recommended during finishing. For a 6mm ball-end mill at 25,000 RPM, this translates to a linear feed rate of approximately 500 to 750 mm/min.

Lower feed rates increase machining time, so a balance must be struck between efficiency and quality. Computer-aided manufacturing (CAM) software, such as UG NX or HyperMill, can optimize feed rates for complex impeller geometries.

Depth of Cut

Depth of cut (DOC) determines the amount of material removed per pass. For finishing operations targeting Ra0.05, a shallow DOC of 0.05 to 0.1 mm is ideal. This minimizes tool deflection and vibration, which can introduce surface imperfections. Multiple light passes are preferred over a single deep cut to ensure consistency across the impeller’s curved surfaces.

For example, a 5-axis CNC machine with a 6mm ball-end tool can use a DOC of 0.05 mm for the final finishing pass, ensuring precise control over surface texture.

Tool Path Strategy

The tool path strategy dictates how the cutting tool navigates the impeller’s complex geometry. For molecular pump impellers, 5-axis simultaneous machining is essential to maintain consistent tool contact and avoid interference with adjacent blades. Common strategies include:

- Spiral Tool Path: Ensures smooth, continuous motion, reducing tool marks and improving surface uniformity.

- Z-Level Finishing: Maintains constant tool engagement along the impeller’s curved surfaces, ideal for achieving Ra0.05.

- Flowline Machining: Follows the natural curvature of the blades, minimizing abrupt direction changes that can cause surface defects.

CAM software optimizes these paths to ensure symmetry and dynamic balance, critical for high-speed impellers. The tool path should also account for the blade’s surface texture requirements, limiting the end mill’s direction to maintain consistent pipeline-like patterns.

Coolant and Lubrication

Coolant application is vital to prevent thermal distortion and tool wear, which can degrade surface finish. For Ra0.05, minimum quantity lubrication (MQL) with a vegetable-based oil is preferred over flood coolant, as it reduces residue buildup on the workpiece. MQL delivers a fine mist of lubricant, maintaining a thin oil film that reduces friction without affecting dimensional accuracy.

For titanium impellers, a coolant pressure of 10 to 20 bar is sufficient to clear chips and maintain tool temperature during high-speed machining.

Tool Selection and Preparation

The choice of cutting tools is critical for achieving Ra0.05. Molecular pump impellers require tools with high rigidity, sharpness, and wear resistance. Key considerations include:

Tool Material

Carbide tools with advanced coatings, such as diamond-like carbon (DLC) or titanium aluminum nitride (TiAlN), are ideal for machining aluminum or titanium impellers. DLC coatings reduce friction and improve chip evacuation, contributing to a smoother surface finish. For example, a 6mm carbide ball-end mill with a DLC coating can achieve Ra0.1 during semi-finishing, setting the stage for final polishing to Ra0.05.

Tool Geometry

Ball-end mills with a radius of 3 to 6 mm are commonly used for finishing impeller blades due to their ability to follow curved surfaces. The tool’s cutting edge length should exceed 70 mm to cover the blade’s height, and the total tool length should be over 120 mm to avoid interference. A high-speed tool holder, such as an HSK-A63, ensures rigidity and minimizes runout.

Tool Condition

Tools must be inspected for wear before each finishing pass. Even minor edge chipping can introduce surface defects, preventing Ra0.05. Regular tool replacement and in-process monitoring using tool wear sensors enhance reliability.

Machine Tool Requirements

A 5-axis CNC machining center is essential for molecular pump impellers due to their complex geometry. Key machine specifications include:

| Parameter | Specification |

|---|---|

| X/Y/Z Axis Travel | 900/600/550 mm |

| C-Axis Rotation | 0° to 360° |

| B-Axis Swing | -90° to +90° |

| Spindle Speed | Up to 30,000 RPM |

| Tool Magazine Capacity | 40 tools |

| CNC System | Siemens 840D or equivalent |

The machine must maintain high positional accuracy (±0.005 mm) and thermal stability to prevent dimensional deviations. Regular calibration and maintenance ensure consistent performance.

Post-Processing Techniques

While CNC machining can achieve surface roughness close to Ra0.1, post-processing is often required to reach Ra0.05. Common techniques include:

Polishing

Manual or automated polishing with diamond paste (1-3 µm grit) refines the surface to Ra0.05. For impellers, automated polishing with a 5-axis robotic arm ensures uniformity across complex geometries. Polishing time typically ranges from 30 to 60 minutes per impeller, depending on size and material.

Vibratory Finishing

Vibratory finishing with ceramic media can smooth micro-imperfections without altering dimensional accuracy. A 2-hour cycle with fine media (0.5 mm) is sufficient to reduce roughness from Ra0.1 to Ra0.05.

Electropolishing

For titanium impellers, electropolishing removes a thin surface layer (5-10 µm), achieving a mirror-like finish. The process uses an electrolyte solution (e.g., sulfuric acid and phosphoric acid) and a current density of 0.5 A/cm² for 10-15 minutes.

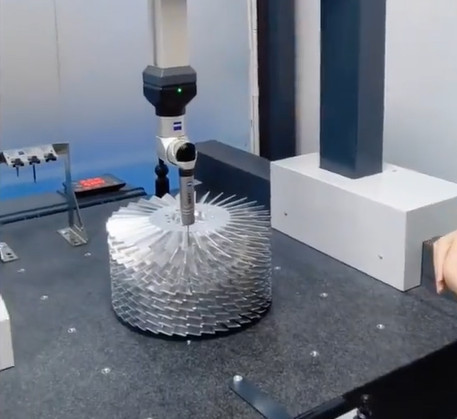

Quality Control and Inspection

Ensuring Ra0.05 requires rigorous quality control. Surface roughness is measured using a profilometer with a stylus radius of 2 µm, capable of detecting deviations as small as 0.01 µm. Inspections should be conducted at multiple points on the blade and hub surfaces to verify uniformity.

Additionally, coordinate measuring machines (CMMs) with ±0.002 mm accuracy verify dimensional tolerances. Dynamic balancing tests at operational speeds (e.g., 90,000 RPM) ensure the impeller’s symmetry and stability, critical for molecular pump performance.

Parameter Optimization Workflow

A systematic approach to parameter optimization enhances repeatability and efficiency. The following workflow is recommended:

- Material Analysis: Characterize the impeller material (e.g., aluminum 7075 or titanium Ti-6Al-4V) to select appropriate tools and parameters.

- Roughing Phase: Use high DOC (0.5-1 mm) and moderate speeds (10,000-15,000 RPM) to remove bulk material efficiently.

- Semi-Finishing: Reduce DOC to 0.1-0.2 mm and increase spindle speed to 18,000-22,000 RPM to prepare the surface for finishing.

- Finishing Phase: Apply parameters outlined above (25,000 RPM, 0.01-0.03 mm/tooth, 0.05 mm DOC) with a spiral or flowline tool path.

- Post-Processing: Polish or electropolish to achieve Ra0.05.

- Inspection: Measure surface roughness and dimensions, and perform dynamic balancing.

Case Study: Parameter Settings for a Titanium Impeller

A 100 mm diameter titanium impeller was machined using a 5-axis CNC center with the following parameters for the finishing phase:

| Parameter | Value |

|---|---|

| Spindle Speed | 25,000 RPM |

| Feed Rate | 0.02 mm/tooth (600 mm/min) |

| Depth of Cut | 0.05 mm |

| Tool | 6 mm carbide ball-end mill, DLC-coated |

| Tool Path | Spiral |

| Coolant | MQL, 15 bar |

After machining, the surface roughness was Ra0.08. A 45-minute automated polishing cycle with 1 µm diamond paste reduced the roughness to Ra0.05, verified by profilometer measurements. The impeller passed dynamic balancing tests at 90,000 RPM, confirming its suitability for molecular pump applications.

Conclusion

Achieving a Ra0.05 surface finish on molecular pump impellers requires precise control over CNC machining parameters, advanced tooling, and effective post-processing. By optimizing spindle speed, feed rate, depth of cut, tool path, and coolant application, manufacturers can produce impellers with exceptional surface quality and performance. A systematic workflow, supported by rigorous quality control, ensures repeatability and reliability. This guide provides a comprehensive framework for professionals seeking to meet the stringent demands of molecular pump impeller production.