Aluminum precision machining is a critical process in manufacturing industries, enabling the production of complex components with tight tolerances. This article explores the technical aspects of aluminum precision machining, including its techniques, applications, and key parameters. It provides a detailed, systematic overview for professionals seeking to understand the process and its implementation in high-demand sectors like aerospace, automotive, and electronics.

Overview of Aluminum Precision Machining

Aluminum precision machining involves the use of advanced tools and computer-controlled systems to shape aluminum alloys into components with exact specifications. Aluminum’s lightweight, high strength-to-weight ratio, corrosion resistance, and excellent machinability make it a preferred material for precision parts. The process requires careful control of cutting parameters, tool selection, and machine setup to achieve tolerances as tight as ±0.001 inches (±0.0254 mm).

The primary techniques include CNC milling, turning, drilling, and grinding, each tailored to specific component geometries and requirements. These methods leverage computer numerical control (CNC) systems to ensure repeatability and accuracy, making them suitable for both small-batch and large-scale production.

Key Techniques in Aluminum Precision Machining

Several machining techniques are employed to achieve precision in aluminum components. Below is a detailed examination of the most common methods.

CNC Milling

CNC milling uses rotating cutting tools to remove material from an aluminum workpiece. It is ideal for creating complex geometries, such as slots, pockets, and contoured surfaces. Modern CNC milling machines operate on 3 to 5 axes, allowing for intricate designs with minimal setups.

Key parameters for CNC milling of aluminum include:

- Spindle Speed: Typically 8,000–20,000 RPM, depending on tool diameter and alloy type.

- Feed Rate: 50–200 inches per minute (IPM) or 1,270–5,080 mm/min for optimal surface finish.

- Depth of Cut: 0.01–0.1 inches (0.25–2.54 mm) per pass to balance material removal rate (MRR) and tool life.

- Coolant: Water-based emulsions or synthetic coolants to reduce heat and chip adhesion.

Tool materials like carbide or polycrystalline diamond (PCD) are preferred for their durability and ability to maintain sharp edges during high-speed operations.

CNC Turning

CNC turning involves rotating the aluminum workpiece against a stationary cutting tool to produce cylindrical or conical shapes. It is widely used for components like shafts, bushings, and fittings. Single-point cutting tools ensure high precision, with tolerances as low as ±0.0005 inches (±0.0127 mm).

Key parameters for CNC turning include:

- Cutting Speed: 300–1,200 feet per minute (FPM) or 91–366 m/min, adjusted for alloy hardness.

- Feed Rate: 0.004–0.012 inches per revolution (IPR) or 0.1–0.3 mm/rev.

- Tool Geometry: Positive rake angles (5–15°) to reduce cutting forces and improve chip evacuation.

Turning aluminum requires careful chip management, as the material tends to produce long, stringy chips that can clog machinery if not properly controlled.

Drilling and Tapping

Drilling creates holes in aluminum components, while tapping adds internal threads for fasteners. High-speed steel (HSS) or carbide drills with polished flutes are used to minimize burr formation and ensure clean holes. For tapping, thread-forming tools are preferred for softer aluminum alloys to avoid chip generation.

Key parameters include:

- Drill Speed: 3,000–10,000 RPM, depending on hole diameter.

- Feed Rate: 0.002–0.008 inches per revolution (IPR) or 0.05–0.2 mm/rev.

- Coolant Pressure: 500–1,000 PSI for through-tool coolant delivery to clear chips.

Proper tool coatings, such as titanium nitride (TiN), enhance tool life and reduce friction during drilling and tapping.

Grinding

Grinding is used for finishing aluminum components to achieve superior surface quality, with roughness values as low as Ra 0.12 µm. It is often employed for flat surfaces or when ultra-tight tolerances are required. Aluminum’s softness necessitates the use of silicon carbide or aluminum oxide wheels to prevent wheel loading.

Key parameters include:

- Wheel Speed: 4,000–6,000 FPM or 1,220–1,830 m/min.

- Feed Rate: 0.001–0.005 inches per pass (0.025–0.127 mm).

- Coolant: High-flow coolant to prevent thermal distortion.

Grinding requires careful wheel dressing to maintain consistent performance and avoid material buildup.

Aluminum Alloys for Precision Machining

Aluminum alloys are categorized into series based on their alloying elements, each suited for specific applications. The table below summarizes common alloys used in precision machining.

| Alloy Series | Main Alloying Elements | Key Properties | Applications |

|---|---|---|---|

| 2000 Series | Copper | High strength, good fatigue resistance | Aerospace components, fuselage structures |

| 6000 Series | Magnesium, Silicon | Good corrosion resistance, weldability | Automotive parts, structural components |

| 7000 Series | Zinc | High strength, moderate corrosion resistance | Aircraft wing skins, high-stress parts |

The choice of alloy impacts machining parameters. For example, 6061 aluminum is easier to machine due to its balanced properties, while 7075 requires slower speeds and higher cutting forces due to its hardness.

Applications of Aluminum Precision Machining

Aluminum precision machining serves industries requiring lightweight, durable, and precise components. Below are key applications.

Aerospace Industry

Aerospace demands components with high strength-to-weight ratios and tight tolerances. Aluminum alloys like 2024 and 7075 are used for wing skins, fuselage frames, and landing gear components. Machining processes achieve tolerances of ±0.001 inches (±0.0254 mm) to meet stringent safety and performance standards.

Example components include:

- Flaperons: Require 5-axis CNC milling for complex aerodynamic shapes.

- Brackets: Use CNC turning for precise cylindrical features.

- Panels: Employ grinding for smooth surfaces with Ra values below 0.4 µm.

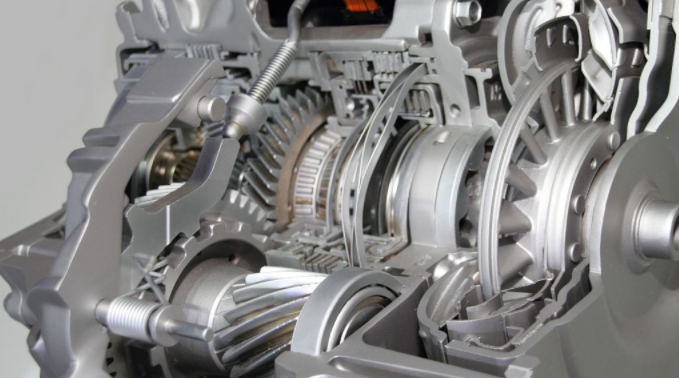

Automotive Industry

Aluminum’s lightweight properties reduce vehicle weight, improving fuel efficiency. Precision machining produces engine blocks, transmission housings, and suspension components from 6061 and 6082 alloys. High-speed machining ensures cost-effective production for large-scale manufacturing.

Example components include:

- Pistons: CNC turning for tight dimensional control.

- Heat Exchangers: Drilling and milling for micro-channel features.

- Chassis Parts: Multi-axis machining for complex geometries.

Electronics Industry

Aluminum’s thermal conductivity makes it ideal for heat sinks and enclosures in electronics. Precision machining ensures fine features for compact devices, with tolerances as low as ±0.0005 inches (±0.0127 mm) for critical components.

Example components include:

- Heat Sinks: CNC milling for intricate fin structures.

- Housings: Turning and milling for precise fits.

- Connectors: Drilling and tapping for threaded features.

Key Parameters for Optimal Machining Performance

Achieving high-quality results in aluminum precision machining requires precise control of parameters. The table below outlines recommended settings for common aluminum alloys.

| Alloy | Spindle Speed (RPM) | Feed Rate (IPM or mm/min) | Cutting Speed (FPM or m/min) | Tool Material |

|---|---|---|---|---|

| 6061 | 10,000–15,000 | 100–150 (2,540–3,810) | 500–800 (152–244) | Carbide |

| 2024 | 8,000–12,000 | 80–120 (2,032–3,048) | 400–600 (122–183) | Carbide/PCD |

| 7075 | 6,000–10,000 | 60–100 (1,524–2,540) | 300–500 (91–152) | PCD |

These parameters vary based on machine capabilities, tool condition, and workpiece geometry. Adjustments may be necessary to optimize MRR, surface finish, and tool life.

Considerations in Aluminum Precision Machining

While aluminum is highly machinable, certain challenges require attention to ensure quality and efficiency.

Chip Management: Aluminum produces stringy chips that can clog tools or damage surfaces. Using chip breakers and high-pressure coolant (500–1,000 PSI) mitigates this issue.

Tool Wear: Softer alloys like 6061 can cause adhesive wear, while harder alloys like 7075 increase abrasive wear. Coated tools (e.g., TiN or diamond-like carbon) extend tool life.

Thermal Effects: Aluminum’s high thermal conductivity reduces heat buildup, but excessive heat can cause dimensional inaccuracies. Coolants and optimized cutting speeds prevent thermal distortion.

Surface Finish: Achieving Ra values below 0.4 µm requires fine-tuned parameters and polished tools. Grinding or secondary finishing may be necessary for critical applications.

Quality Control in Aluminum Precision Machining

Quality control ensures components meet specifications. Common methods include:

- Coordinate Measuring Machines (CMM): Verify dimensions with accuracy up to ±0.0001 inches (±0.00254 mm).

- Surface Profilometry: Measures roughness (Ra, Rz) to ensure compliance with standards.

- Non-Destructive Testing (NDT): Detects internal defects like voids or cracks using ultrasonic or X-ray methods.

Regular tool inspection and machine calibration are critical to maintaining consistent quality.

Conclusion

Aluminum precision machining is a cornerstone of modern manufacturing, enabling the production of high-quality components for aerospace, automotive, and electronics industries. By leveraging CNC milling, turning, drilling, and grinding, manufacturers achieve tolerances as tight as ±0.0005 inches (±0.0127 mm) and surface finishes as smooth as Ra 0.12 µm. Careful selection of alloys, tools, and parameters ensures efficiency and quality. With robust quality control and attention to challenges like chip management and tool wear, aluminum precision machining delivers reliable, high-performance parts for demanding applications.