Brass, an alloy of copper and zinc, is a versatile material widely used in manufacturing due to its excellent machinability, corrosion resistance, and aesthetic appeal. This guide provides a detailed exploration of brass, its applications across industries, and the intricacies of machining processes, with a focus on precision, complexity, and material properties. The content is structured to offer a systematic understanding for engineers, manufacturers, and professionals involved in brass component production.

Understanding Brass: Composition and Properties

Brass is primarily composed of copper and zinc, with the ratio of these elements determining its mechanical and chemical properties. Typical compositions range from 55% to 95% copper and 5% to 45% zinc, with trace elements like lead, tin, or aluminum added to enhance specific characteristics. Lead, for example, improves machinability, while tin enhances corrosion resistance, particularly in marine environments.

The alloy’s properties make it suitable for a wide range of applications. Brass exhibits high ductility, allowing it to be formed into complex shapes. Its corrosion resistance ensures durability in harsh environments, such as plumbing or marine settings. Additionally, brass has good electrical and thermal conductivity, making it ideal for electrical components and heat exchangers. The material’s golden-yellow or reddish hue, depending on copper content, also adds aesthetic value for decorative applications.

Brass is classified into several types based on its zinc content and microstructure:

- Alpha Brasses: Contain 67–72% copper and 28–33% zinc, offering high ductility and cold-working capabilities. Suitable for pressing and forging.

- Alpha-Beta Brasses: With 55–65% copper and 35–45% zinc, these are suited for hot working and have a balance of strength and ductility.

- Beta Brasses: Higher zinc content (above 45%) makes them harder and stronger but less ductile, typically used for casting.

Common brass grades include C260 (Cartridge Brass), C360 (Free Machining Brass), and C464 (Naval Brass), each tailored for specific applications based on their properties.

Applications of Brass Across Industries

Brass’s versatility makes it a preferred material in numerous industries. Its combination of machinability, durability, and corrosion resistance allows it to serve both functional and aesthetic purposes. Below are key applications of brass in various sectors:

Plumbing and Pipe Fittings

Brass is widely used in plumbing due to its corrosion resistance and ability to withstand water exposure. Components such as valves, couplings, and pipe fittings benefit from brass’s durability and machinability. For instance, C360 brass is commonly used for fittings due to its excellent machinability, while C230 (Red Brass) is preferred for pipelines in corrosive environments.

Electrical and Electronics

The high electrical conductivity of brass, primarily due to its copper content, makes it ideal for electrical connectors, terminals, and switches. Brass’s ability to be machined into precise components ensures reliable performance in electronic devices. C260 brass, with its balance of conductivity and formability, is often used in these applications.

Automotive Industry

In automotive manufacturing, brass is used for radiator cores, sensors, and fuel system fittings. Its thermal conductivity and corrosion resistance ensure long-lasting performance in demanding conditions. C377 (Forging Brass) is often selected for parts requiring both strength and machinability.

Aerospace Components

Brass is employed in non-critical aerospace components, such as fittings and fasteners, where its non-magnetic properties and corrosion resistance are advantageous. C464 Naval Brass is frequently used in marine aerospace applications due to its resistance to saltwater corrosion.

Musical Instruments

The acoustic properties and aesthetic appeal of brass make it a staple in the production of musical instruments like trumpets, trombones, and saxophones. C260 brass is commonly used for its formability and rich golden tone, which enhances both sound quality and visual appeal.

Decorative and Architectural Uses

Brass’s attractive appearance makes it a popular choice for architectural hardware, such as door handles, railings, and decorative panels. C385 (Architectural Bronze) is often used for its formability and aesthetic finish in extrusions and fittings.

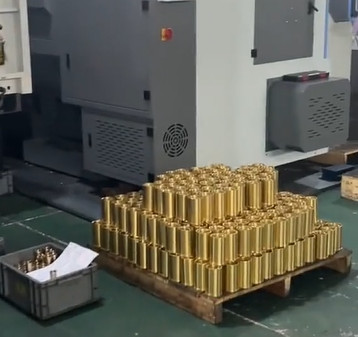

CNC Machining of Brass: Processes and Techniques

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses programmed tools to remove material from a brass workpiece, creating precise components. Brass’s excellent machinability, characterized by high feed rates and minimal tool wear, makes it a preferred material for CNC machining. This section explores the key processes, precision requirements, and complexities involved in brass machining.

Key CNC Machining Processes for Brass

Several CNC machining processes are used to shape brass, each suited to specific component geometries and requirements:

| Process | Description | Applications |

|---|---|---|

| Milling | Uses rotating cutting tools to remove material, creating complex shapes, slots, and flat surfaces. | Gears, fittings, and electronic components. |

| Turning | Rotates the workpiece against a stationary cutting tool to produce cylindrical parts. | Bushings, shafts, and fittings. |

| Drilling | Creates precise holes using rotating drill bits. | Fasteners and fluid passages. |

| Tapping | Forms internal threads in drilled holes for screws or bolts. | Threaded fittings and fasteners. |

| Reaming | Refines drilled holes for improved size, shape, and surface finish. | Precision components requiring tight tolerances. |

These processes are often combined in multi-axis CNC machines, such as 5-axis systems, to produce complex geometries with high precision.

Precision in Brass Machining

Brass machining achieves tight tolerances, often within ±0.005 mm for high-precision applications. This precision is critical in industries like aerospace and electronics, where components must meet exact specifications. For example, C360 brass, with its 100% machinability rating, allows for high-speed machining with tolerances as low as ±0.002 mm in advanced setups. The material’s dimensional stability ensures that parts maintain their shape during and after machining, reducing the need for additional finishing.

Precision is influenced by several factors:

- Machine Calibration: CNC machines must be calibrated to maintain accuracy, especially for intricate designs.

- Tool Selection: Carbide tools are preferred for their durability and ability to maintain sharp edges during high-speed machining.

- Cutting Parameters: Optimal spindle speeds (e.g., 1000–3000 RPM for C360 brass) and feed rates (0.1–0.3 mm/rev) ensure smooth cuts and minimal tool wear.

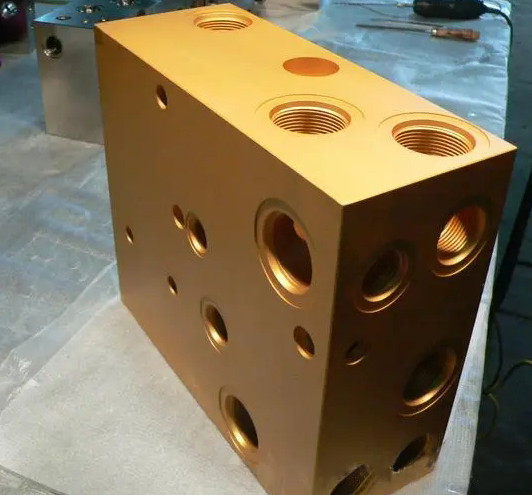

Complexity in Brass Machining

Brass’s machinability allows for the production of complex geometries, such as intricate fittings or multi-faceted components. However, complexity introduces specific considerations:

- Design for Manufacturability (DfM): Complex designs may require multiple machine setups, increasing production time and cost. Simplifying designs or minimizing setups can enhance efficiency.

- Tool Path Optimization: Advanced CAM (Computer-Aided Manufacturing) software is used to generate efficient tool paths, reducing machining time for complex parts.

- Material Selection: Grades like C360 are ideal for complex parts due to their machinability, while C200 grades may be less suitable due to higher copper content, which can reduce cutting efficiency.

For example, producing a brass valve with internal threads and external grooves requires milling, drilling, and tapping, often in a single 5-axis CNC setup to maintain precision and reduce setup time.

Machining Difficulty and Material Considerations

While brass is easier to machine than materials like titanium or stainless steel, certain factors influence machining difficulty:

- Alloy Composition: High-copper alloys (e.g., C210, 95% copper) are softer and more ductile, making them slightly harder to machine than leaded brasses like C360.

- Surface Finish Requirements: Achieving a mirror-like finish may require additional processes like buffing or polishing, increasing production time.

- Heat Generation: Although brass requires minimal coolant due to its low friction, high-speed machining can generate heat, potentially affecting dimensional accuracy if not managed properly.

To address these challenges, machinists use sharp tools, appropriate cutting speeds, and light lubrication to maintain precision and surface quality. For instance, C360 brass can be machined at speeds up to 4000 RPM with minimal coolant, while C230 requires lower speeds (2000–3000 RPM) to prevent work hardening.

Prototyping with Brass

Brass is widely used in prototyping due to its ease of machining and ability to produce high-quality, functional parts quickly. CNC machining allows for rapid prototyping of brass components, enabling design validation before full-scale production. For example, a prototype brass fitting can be machined in under 5 days, depending on complexity, using C360 brass for its high machinability. Prototyping also benefits from brass’s recyclability, as scraps can be melted and reused, reducing material costs.

Common Brass Grades for CNC Machining

Selecting the appropriate brass grade is critical for optimizing machining outcomes. The following table summarizes key brass grades, their compositions, and applications:

| Grade | Composition | Properties | Applications |

|---|---|---|---|

| C260 (Cartridge Brass) | 70% Cu, 30% Zn | High ductility, good conductivity, bright finish | Plumbing fittings, electrical connectors, musical instruments |

| C360 (Free Machining Brass) | 60% Cu, 35.5% Zn, 3.7% Pb | 100% machinability, high precision | Gears, bushings, fittings |

| C464 (Naval Brass) | 59% Cu, 40% Zn, 1% Sn | Superior corrosion resistance, strength | Marine fittings, fasteners |

| C230 (Red Brass) | 85% Cu, 15% Zn | High corrosion resistance, reddish hue | Pipelines, decorative hardware |

Each grade is selected based on the specific requirements of the project, such as machinability, corrosion resistance, or aesthetic appeal.

Surface Finishing Options for Brass Components

Surface finishing enhances the functionality and appearance of brass parts. Common finishes include:

- As-Machined: Retains the natural surface, prioritizing function over aesthetics. Suitable for non-decorative parts but may be less resistant to wear.

- Polishing: Uses abrasive wheels to create a smooth, reflective surface, ideal for decorative applications.

- Electroplating: Coats brass with metals like chrome or gold to enhance corrosion resistance and appearance.

- Honing: Produces a cross-hatched pattern for improved precision and surface quality in functional components.

The choice of finish depends on the part’s application, with polishing and electroplating being common for decorative or corrosion-sensitive components.

Conclusion

Brass is a highly versatile material valued for its machinability, corrosion resistance, and aesthetic appeal. Its applications span plumbing, electronics, automotive, aerospace, and musical instruments, driven by its unique properties. CNC machining of brass enables the production of precise, complex components with high efficiency, supported by processes like milling, turning, and drilling. By selecting the appropriate brass grade and optimizing machining parameters, manufacturers can achieve tight tolerances and high-quality finishes. This guide provides a comprehensive resource for professionals seeking to leverage brass in manufacturing, emphasizing technical precision and systematic approaches to material selection and machining.