KeSu offers CNC on Demand services, delivering a reliable one-stop solution for precision CNC machining. Whether you need rapid prototyping, end-use part production, or custom tooling, KeSu's advanced capabilities cater to small, medium, and large-sized parts across various industries. As a leading CNC machining supplier in China, KeSu combines cutting-edge technology with expertise to produce high-quality parts in a wide range of materials, including metals and hard plastics.

This article explores the intricacies of CNC on Demand, detailing how it works, its benefits, material options, cost factors, and applications. Whether you're in aerospace, automotive, medical, or robotics, KeSu's CNC machining services are designed to meet your precision manufacturing needs.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled machining tools to remove material from a workpiece, shaping it into a precise final design. By employing high-precision cutting tools, CNC machining creates parts with tight tolerances and complex geometries, making it ideal for both prototyping and production.

How CNC Machining Works

The CNC machining process begins with a digital design, typically created using CAD (Computer-Aided Design) software. KeSu's engineers convert these designs into programming instructions known as G-code, which dictates the tool paths and movements of the CNC machining. The machining then executes these instructions, precisely controlling the cutting tools to shape the workpiece.

- CAD Design: Customers provide a 2D or 3D CAD model of the part.

- G-Code Programming: Engineers translate the CAD model into machining-readable instructions.

- Machining: The CNC machining moves and rotates cutting tools to remove material according to the G-code.

- Finishing: Post-processing, such as polishing or anodizing, may be applied to achieve the desired surface finish.

Common CNC machinings include vertical milling machinings, horizontal milling machinings, lathes, and router planers, each suited for specific tasks and part geometries.

Types of CNC Machinings

KeSu utilizes a variety of CNC machinings to meet diverse manufacturing needs. Below is a table summarizing the primary types of CNC machinings and their applications:

| Machining Type | Description | Applications |

|---|---|---|

| Vertical Milling Machining | Features a vertically oriented spindle, ideal for flat surfaces and slots. | Prototyping, flat parts, and complex 3D shapes. |

| Horizontal Milling Machining | Has a horizontally oriented spindle, suitable for heavy-duty cutting. | Large parts, gear cutting, and slots. |

| CNC Lathe | Rotates the workpiece against a stationary cutting tool for cylindrical parts. | Shafts, bushings, and threaded components. |

| Router Planer | Uses high-speed spindles for cutting softer materials like wood or plastics. | Signage, decorative parts, and plastic components. |

Why Choose CNC on Demand?

CNC on Demand by KeSu offers a fast, accurate, and versatile machining solution tailored to modern manufacturing needs. Here are the key reasons to choose CNC machining for your projects:

Precision and Accuracy

CNC machining achieves tolerances as tight as ±0.001 inches (±0.025 mm), ensuring parts meet exact specifications. This precision is critical for industries like aerospace and medical devices, where even minor deviations can impact performance.

Scalability and Reusability

Once a CNC program is created, it can be reused to produce any number of identical parts, making it highly scalable. Whether you need a single prototype or low-volume production runs, KeSu's CNC on Demand services deliver consistent results.

Material Versatility

CNC machining supports a wide range of materials, from metals like aluminum and titanium to hard plastics like ABS and PEEK. This versatility allows KeSu to serve diverse industries with varying material requirements.

Cost-Effectiveness

While initial setup costs for programming and tooling may apply, CNC machining becomes cost-effective for repeated production. The ability to produce complex parts in a single setup reduces labor and time, lowering overall costs.

Materials for CNC Machining

KeSu's CNC on Demand services support an extensive selection of materials, ensuring compatibility with your project's requirements. Below is a detailed overview of commonly used materials and their properties:

Metals

Metals are widely used in CNC machining due to their durability and strength. KeSu offers the following metal options:

- Aluminum: Lightweight, corrosion-resistant, and easy to machine. Ideal for aerospace and automotive parts.

- Stainless Steel: High strength and corrosion resistance, suitable for medical and marine applications.

- Titanium: Exceptional strength-to-weight ratio and biocompatibility, used in aerospace and medical implants.

- Copper: Excellent electrical conductivity, perfect for electrical components.

Plastics

Hard plastics are increasingly popular for CNC machining due to their affordability and versatility. KeSu supports:

- ABS: Durable and impact-resistant, used in consumer goods and prototypes.

- PEEK: High-performance plastic with excellent thermal and chemical resistance, ideal for medical and aerospace applications.

- Polycarbonate: Transparent and tough, suitable for optical and protective components.

- Nylon: Strong and wear-resistant, used for gears and bearings.

Material Selection Guide

Choosing the right material depends on your project's requirements. The table below provides a quick reference for material properties and applications:

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, good thermal conductivity | Aerospace components, automotive parts |

| Stainless Steel | High strength, corrosion-resistant | Medical devices, marine hardware |

| Titanium | High strength-to-weight ratio, biocompatible | Aerospace, medical implants |

| PEEK | High thermal and chemical resistance | Medical devices, aerospace components |

| ABS | Impact-resistant, cost-effective | Prototypes, consumer goods |

For specific material recommendations, contact KeSu's team to discuss your project's needs.

Cost Factors in CNC Machining

The cost of CNC machining depends on several factors, including material choice, machining time, part complexity, and order quantity. KeSu provides transparent pricing through detailed manufacturing analyses based on your CAD drawings.

Key Cost Drivers

Understanding the factors that influence CNC machining costs can help you optimize your project budget:

- Material Costs: Premium materials like titanium or PEEK are more expensive than aluminum or ABS.

- Machining Time: Complex parts with intricate geometries require longer machining times, increasing costs.

- Part Complexity: Features like tight tolerances or undercuts may require specialized tools or additional setups.

- Order Quantity: Larger production runs benefit from economies of scale, reducing the cost per part.

How to Get a Quote

To receive an accurate cost estimate, submit your CAD drawings to KeSu. Within a few hours, you'll receive a detailed manufacturing analysis and quotation tailored to your project. This rapid turnaround ensures you can make informed decisions quickly.

Applications of CNC on Demand

KeSu's CNC on Demand services support a wide range of industries, delivering precision parts and prototypes for various applications. Below are some key sectors and their use cases:

Aerospace

CNC machining produces lightweight, high-strength components for aircraft and spacecraft, such as turbine blades, structural brackets, and landing gear parts. Materials like aluminum and titanium are commonly used for their performance under extreme conditions.

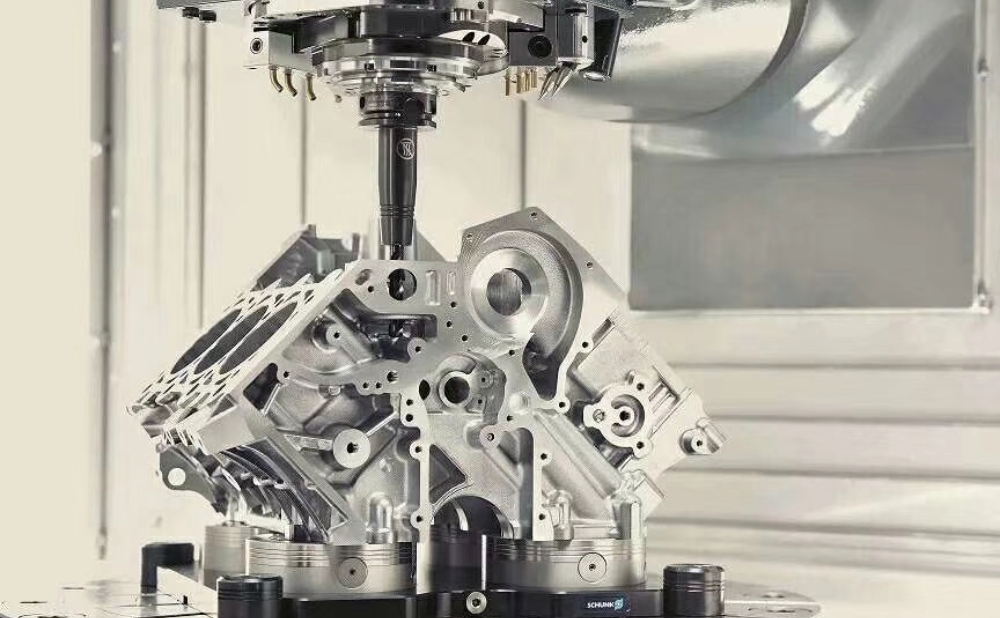

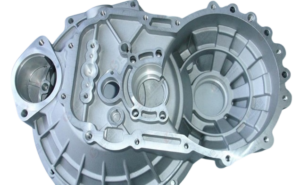

Automotive

The automotive industry relies on CNC machining for engine components, transmission parts, and custom fittings. KeSu's ability to produce parts with tight tolerances ensures optimal performance and safety.

Medical Devices

CNC machining is critical for manufacturing surgical instruments, implants, and diagnostic equipment. Biocompatible materials like titanium and PEEK are often used to meet stringent regulatory standards.

Electronics

From heat sinks to connector housings, CNC machining creates precise components for electronic devices. Copper and aluminum are popular for their conductivity and thermal properties.

Other Industries

KeSu also serves defense, industrial automation, machinery, oil and gas, and robotics, producing custom parts like gears, housings, and fixtures. The versatility of CNC machining makes it a go-to solution for complex manufacturing challenges.

CNC Machining Technologies at KeSu

KeSu employs advanced CNC machining technologies to deliver high-quality parts efficiently. Below are the primary techniques used in CNC on Demand services:

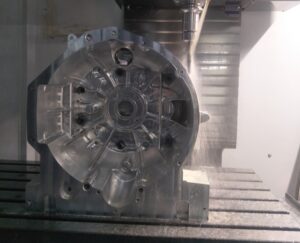

CNC Milling

CNC milling uses rotating cutting tools to remove material from a stationary workpiece. It's ideal for creating flat surfaces, slots, and complex 3D shapes. KeSu's 3-axis, 4-axis, and 5-axis milling machinings handle a wide range of part geometries.

CNC Turning

CNC turning rotates the workpiece against a stationary cutting tool, making it perfect for cylindrical parts like shafts and bushings. KeSu's lathes ensure high precision and smooth surface finishes.

Wire EDM

Wire Electrical Discharge Machining (EDM) uses a thin wire to cut intricate shapes in conductive materials. It's ideal for parts requiring tight tolerances and complex contours, such as tooling and molds.

Why KeSu for CNC on Demand?

KeSu stands out as a trusted provider of CNC on Demand services due to its commitment to quality, speed, and customer satisfaction. Here's why KeSu is the right choice:

- Expertise: Over a decade of experience in precision CNC machining.

- Advanced Technology: State-of-the-art CNC machinings for superior accuracy and efficiency.

- Rapid Turnaround: Fast quotes and production timelines to meet tight deadlines.

- Comprehensive Services: From prototyping to low-volume production and finishing.

- Global Reach: Serving clients worldwide with reliable logistics and support.

Frequently Asked Questions (FAQ)

What is CNC on Demand?

CNC on Demand is a service offered by KeSu that provides rapid, precision CNC machining for prototyping and end-use parts. It combines advanced technology with flexible production to meet diverse manufacturing needs.

What materials can I use with KeSu's CNC machining?

KeSu supports a wide range of materials, including aluminum, stainless steel, titanium, copper, ABS, PEEK, polycarbonate, and nylon. Contact KeSu for specific material inquiries.

How much does CNC machining cost?

Costs depend on material, machining time, part complexity, and order quantity. Submit your CAD drawings to KeSu for a detailed quote within hours.

What industries does KeSu serve?

KeSu serves aerospace, automotive, medical, electronics, defense, industrial automation, machinery, oil and gas, and robotics, among others.

How do I get started with CNC on Demand?

Contact KeSu with your CAD drawings or project specifications. The team will provide a manufacturing analysis and quotation to kickstart your project.

Get Started with CNC on Demand Today

KeSu's CNC on Demand services offer a reliable, high-precision solution for your manufacturing needs. Whether you're developing a prototype or producing end-use parts, KeSu's expertise and advanced technology ensure exceptional results. Submit your CAD drawings today to receive a fast, detailed quote and bring your ideas to life.

Contact KeSu for more information or to start your project.