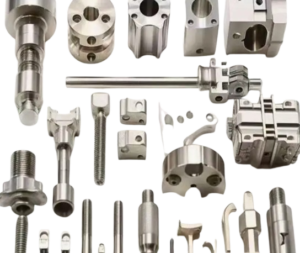

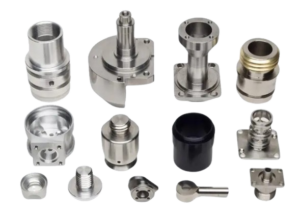

Are you searching for a trusted partner for high-precision CNC turning company services in China? At Kesu, we specialize in delivering rapid, reliable, and cost-effective CNC machining solutions for prototyping and production. Our ISO 9001:2015-certified facilities, state-of-the-art CNC technology, and expert team ensure that your parts are manufactured to exact specifications and delivered on time. This comprehensive guide explores our CNC turning services, including the process, materials, surface finishes, applications, and why Kesu is your ideal manufacturing partner.

What is CNC Turning?

CNC turning is a subtractive manufacturing process that uses computer numerical control (CNC) to create precision parts by rotating a workpiece against a stationary cutting tool. This process is ideal for producing cylindrical or symmetrical components with high accuracy and excellent surface finishes. At Kesu, our CNC turning services are designed for rapid prototyping, low-to-high volume production, and custom applications across various industries.

The CNC Turning Process

CNC turning involves several key steps to transform raw material into a finished part. Below is an overview of the process:

- CAD Design: The process begins with a computer-aided design (CAD) model of the desired part, created using software like SolidWorks or AutoCAD.

- CAM Programming: The CAD model is imported into computer-aided manufacturing (CAM) software, which generates G-code to control the CNC lathe’s movements.

- Material Setup: A cylindrical workpiece (typically a metal or plastic bar) is mounted in the CNC lathe’s chuck or collet.

- Machining: The workpiece rotates at speeds ranging from 1,000 to 10,000 RPM, while the cutting tool moves along the X, Y, or Z axes to remove material and shape the part.

- Finishing: Post-machining processes, such as deburring, polishing, or surface treatment, are applied to achieve the desired finish.

- Inspection: Parts undergo rigorous quality checks using tools like CMM (coordinate measuring machines) to ensure tolerances as tight as ±0.001 mm.

Key Parameters in CNC Turning

To achieve optimal results, CNC turning requires precise control of several parameters. These include:

- Spindle Speed: Typically ranges from 1,000 to 10,000 RPM, depending on the material and part geometry.

- Feed Rate: The speed at which the cutting tool moves, usually between 0.05 to 0.5 mm/rev for precision parts.

- Cutting Depth: Varies from 0.1 to 5 mm per pass, balancing material removal rate and tool life.

- Tool Material: Common tools include carbide, high-speed steel (HSS), or diamond-tipped inserts for enhanced durability.

- Tolerances: CNC turning can achieve tolerances as tight as ±0.001 mm for high-precision applications.

- Surface Roughness: Achieves surface finishes with Ra values as low as 0.4 µm for polished parts.

Benefits of CNC Turning Company

Kesu’s CNC turning services offer unmatched precision, versatility, and efficiency. Below are the key advantages of partnering with us:

High Precision and Quality

Our CNC turning services produce parts with exceptional accuracy, achieving tolerances as tight as ±0.001 mm. Our ISO 9001:2015-certified facilities and rigorous quality control processes ensure that every part meets industry standards. We use advanced inspection tools, such as CMM and laser scanners, to verify dimensions and surface quality.

Wide Material Compatibility

We offer a broad selection of materials to meet diverse application needs. Common materials include:

- Metals: Aluminium (6061, 7075), stainless steel (304, 316), steel (1018, 4140), brass (C360), copper (C101), titanium (Grade 5), and special alloys (Inconel 625, Monel).

- Plastics: POM (Delrin), PTFE (Teflon), PEEK, PC (polycarbonate), PMMA (acrylic), ABS, and PPS.

- Material Properties: For example, aluminium 6061 offers a tensile strength of 310 MPa, while PEEK provides excellent chemical resistance and a melting point of 343°C.

Versatile Surface Finishes

We provide a range of surface treatments to enhance the appearance, durability, and functionality of CNC-turned parts. Options include:

- As-Machined: Leaves a uniform finish with Ra values of 0.8–1.6 µm, ideal for functional parts.

- Sandblasting: Creates a matte finish with grit sizes from 120 to 320 for varying roughness.

- Anodizing: Type II (decorative, 5–25 µm thickness) and Type III (hardcoat, 25–50 µm thickness) for corrosion and wear resistance, available in colors like black, red, and blue.

- Powder Coating: Applies a durable layer (50–150 µm thick) in various colors, offering superior abrasion resistance compared to traditional paint.

Cost-Effective Manufacturing

At Kesu, we adhere to Design for Manufacturability (DFM) principles to optimize part designs, reducing material waste and machining time. Our high-speed CNC lathes, with cycle times as low as 30 seconds per part, enable cost-effective production for both prototypes and large batches. Our location in the Greater Bay Area ensures proximity to major shipping ports, minimizing delivery costs and lead times.

Rapid Turnaround and Delivery

Our streamlined processes and advanced CNC equipment allow us to offer lead times as short as 3–5 days for prototypes and 7–14 days for production runs. Our strategic location facilitates fast shipping, with delivery times to North America and Europe typically ranging from 5 to 10 days.

Custom CNC Turning Solutions

We specialize in custom CNC turning for unique requirements, such as replacing obsolete parts, machining difficult materials like titanium or Inconel, or producing components with complex geometries. Our team provides end-to-end support, from design consultation to supplier management, ensuring a seamless experience.

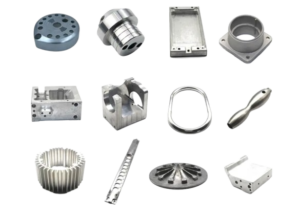

Applications of CNC Turning

CNC turning is ideal for producing cylindrical and symmetrical parts used across various industries. Below are some common applications, along with their specific requirements:

Automotive Industry

CNC turning is widely used in automotive manufacturing for components requiring high precision and durability. Examples include:

- Shafts: Require tolerances of ±0.005 mm and surface finishes of Ra 0.8 µm for smooth operation.

- Bushings: Made from materials like brass or stainless steel, with tensile strengths up to 500 MPa.

- Fuel Injector Nozzles: Demand micro-drilling and tolerances of ±0.002 mm for precise fuel delivery.

Aerospace Industry

Aerospace applications require lightweight, high-strength parts that meet stringent standards. CNC turning is used for:

- Landing Gear Components: Made from titanium (Grade 5, yield strength 880 MPa) for durability and weight reduction.

- Turbine Shafts: Require tight tolerances (±0.001 mm) and high-temperature resistance (up to 600°C).

- Fasteners: Produced from Inconel 718, offering corrosion resistance and strength at 1,300 MPa.

Medical Industry

CNC turning produces precision components for medical devices, where biocompatibility and accuracy are critical. Examples include:

- Surgical Instruments: Made from stainless steel (316L) with surface finishes of Ra 0.4 µm for hygiene.

- Implants: Titanium components with tolerances of ±0.003 mm for precise fit.

- Catheter Components: PEEK parts with chemical resistance and dimensional stability at 150°C.

Electronics Industry

CNC turning supports the production of connectors, housings, and other electronics components. Applications include:

- Connectors: Brass or copper parts with conductivity up to 59 MS/m and tolerances of ±0.005 mm.

- Heat Sink Bases: Aluminium 6061 components with thermal conductivity of 167 W/m·K.

- Enclosure Rings: Anodized aluminium parts with Type II finishes for corrosion resistance.

Why Choose Kesu Company for CNC Turning Services?

Kesu’s CNC turning services combine advanced technology, skilled expertise, and a customer-centric approach to deliver superior results. Here’s why we stand out:

- World-Class Facilities: Our ISO 9001:2015-certified machine shop features 3-, 4-, and 5-axis CNC lathes, capable of handling parts up to 4 meters in length.

- Experienced Team: Our engineers, machinists, and quality specialists work collaboratively to ensure precision and reliability.

- Comprehensive Services: We complement CNC turning with milling, EDM, 3D printing, and injection molding for end-to-end manufacturing solutions.

- Competitive Pricing: Upload your CAD files for instant quotes, and we’ll match or beat competitors’ prices.

- Global Reach: Our location in the Greater Bay Area ensures fast delivery to clients worldwide, with logistics support for seamless communication.

Whether you need prototypes, low-volume batches, or high-volume production, Kesu’s CNC turning services provide the precision, speed, and quality you demand.

Frequently Asked Questions (FAQ)

What is CNC turning?

CNC turning is a subtractive manufacturing process that uses computer-controlled lathes to shape cylindrical or symmetrical parts by rotating a workpiece against a stationary cutting tool.

What materials are available for CNC turning?

We offer a wide range of materials, including metals (aluminium, stainless steel, brass, titanium) and plastics (POM, PEEK, PTFE, PC), as well as special alloys like Inconel.

What tolerances can CNC turning achieve?

CNC turning can achieve tolerances as tight as ±0.001 mm, making it suitable for high-precision applications in industries like aerospace and medical.

What surface finishes are available?

We provide as-machined, sandblasted, anodized (Type II and III), and powder-coated finishes, with surface roughness as low as Ra 0.4 µm.

How fast is your turnaround time?

Prototypes can be delivered in 3–5 days, while production runs typically take 7–14 days, with expedited options available.

Do you offer custom CNC turning services?

Yes, we provide bespoke CNC turning for complex geometries, difficult materials, and unique requirements, with full design and supplier management support.