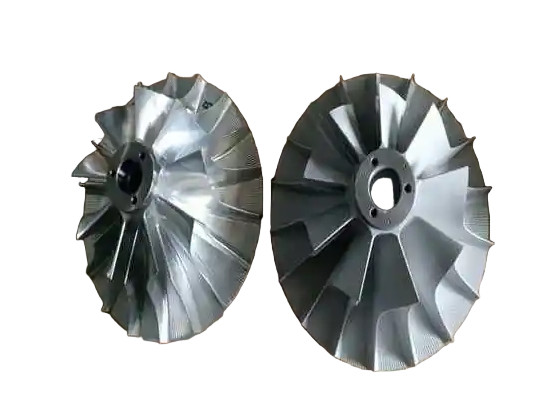

Titanium alloy impellers are critical components in industries such as aerospace, automotive, and medical devices due to their high strength-to-weight ratio, corrosion resistance, and biocompatibility. To optimize their performance, surface treatment processes like sandblasting and hardness enhancement techniques are often combined. This article provides a detailed, technical overview of these processes, focusing on their application to titanium alloy impellers, with specific parameters and practical considerations to ensure durability, reliability, and performance.

Sandblasting Process for Titanium Alloy Impellers

Sandblasting, also known as abrasive blasting, is a mechanical surface treatment method that uses high-velocity abrasive particles to clean, roughen, or modify the surface of titanium alloy impellers. The process removes oxide layers, contaminants, and surface irregularities, while enhancing surface roughness to improve coating adhesion and mechanical properties.

Purpose and Benefits

The primary objectives of sandblasting titanium alloy impellers include:

- Surface Cleaning: Removes oxide layers, dirt, and manufacturing residues to prepare the surface for subsequent treatments or coatings.

- Surface Roughening: Increases surface area and roughness, promoting mechanical interlocking for coatings or bonding in composite structures.

- Stress Induction: Introduces compressive residual stresses, enhancing fatigue resistance and stress corrosion cracking resistance.

- Improved Adhesion: Enhances the bonding strength of coatings, paints, or adhesives applied to the impeller surface.

In aerospace applications, sandblasting improves the fatigue resistance of impeller blades, ensuring reliability under high-stress conditions. In medical applications, such as titanium alloy implants, sandblasting enhances osseointegration by increasing surface area for cell adhesion.

Abrasive Materials and Parameters

The choice of abrasive material and process parameters significantly affects the outcome of sandblasting. Common abrasives for titanium alloys include:

| Abrasive Material | Hardness (HV) | Particle Size (μm) | Applications |

|---|---|---|---|

| White Corundum (Al₂O₃) | 2000–2200 | 50–250 | High hardness, ideal for roughening and cleaning hard titanium surfaces |

| Silica Sand (SiO₂) | 1100–1200 | 50–150 | Milder treatment, suitable for less aggressive surface modification |

| Zirconia (ZrO₂) | 1200–1400 | 90–250 | Biocompatible, used for medical-grade titanium impellers |

Key sandblasting parameters include:

- Pressure: Typically maintained below 0.45 MPa to prevent excessive surface damage. Lower pressures (0.2–0.3 MPa) are used for delicate impeller geometries.

- Nozzle Distance: Ranges from 20 mm to 400 mm, depending on the impeller size and desired surface finish. Closer distances increase intensity but risk surface pitting.

- Spray Angle: Controlled between 20° and 70° to optimize abrasive impact and minimize material loss.

- Duration: Varies based on surface requirements, typically 5–15 minutes, to achieve uniform roughness (Ra 0.5–3 µm).

For example, sandblasting with 110 µm Al₂O₃ particles at 0.4 MPa, with a nozzle distance of 100 mm and a 45° angle, can achieve a surface roughness of Ra 1.5–2.5 µm, suitable for coating adhesion in aerospace impellers.

Process Considerations

Sandblasting titanium alloy impellers requires careful control to avoid issues such as:

- Overblasting: Excessive pressure or duration can cause surface microcracks or material loss, especially in thin-walled impeller blades (≤2 mm).

- Abrasive Embedding: Harder abrasives like Al₂O₃ may embed particles in the titanium surface, potentially affecting biocompatibility or coating performance. Zirconia is preferred for medical applications to minimize this risk.

- Uniformity: Complex impeller geometries require automated sandblasting systems to ensure consistent coverage and avoid overspray or underspray in critical areas.

To address these considerations, impellers are often fixed on specialized tables or supported by tooling to maintain stability during blasting. For thin or delicate impellers, a supporting tool matching the blade's shape is used to prevent deformation.

Hardness Enhancement Techniques for Titanium Alloy Impellers

Hardness enhancement techniques are employed to improve the surface and subsurface properties of titanium alloy impellers, increasing wear resistance, fatigue life, and durability under operational stresses. Common methods include shot peening, heat treatment, and surface coatings, often combined with sandblasting to maximize performance.

Shot Peening

Shot peening is a cold-working process that bombards the impeller surface with spherical media (e.g., steel or ceramic shot) to induce compressive residual stresses and enhance hardness. This process is particularly effective for titanium alloy impellers in aerospace applications, where fatigue resistance is critical.

Parameters:

- Shot Material: Steel shot (300–500 HV) or ceramic shot (700–800 HV), with diameters of 0.5–2 mm.

- Intensity: Measured in Almen strip units (0.1–0.3 mmA), adjusted based on impeller thickness and alloy type.

- Coverage: 100–200% to ensure uniform stress distribution.

- Pressure: 0.3–0.6 MPa, with a nozzle distance of 50–150 mm.

For Ti-6Al-4V impellers, shot peening with 0.8 mm ceramic shot at 0.4 MPa and 150% coverage can increase surface hardness by 10–20% (from 320 HV to 350–380 HV) and introduce compressive stresses up to -80 MPa at a depth of 20 µm.

Benefits:

- Increases surface hardness and fatigue life by counteracting tensile stresses.

- Reduces the risk of stress corrosion cracking in high-stress environments.

- Enhances wear resistance, critical for impellers in abrasive or erosive conditions.

Heat Treatment

Heat treatment processes, such as solution treatment, annealing, and aging, are used to modify the microstructure of titanium alloys, enhancing hardness and mechanical properties. For impellers, heat treatment is often applied post-sandblasting to refine grain structure and relieve residual stresses.

Common Heat Treatment Processes:

| Process | Temperature (°C) | Duration | Effect |

|---|---|---|---|

| Solution Treatment | 900–1000 | 1–2 hours | Dissolves secondary phases, improves strength |

| Annealing | 530–670 | 2–4 hours | Reduces residual stresses, increases ductility |

| Aging | 400–600 | 4–8 hours | Precipitation hardening, increases yield strength |

For example, solution treatment of Ti-6Al-4V at 950°C for 2 hours, followed by water quenching and aging at 500°C for 6 hours, can increase hardness from 320 HV to 360–400 HV, improving wear resistance for impeller applications.

Considerations:

- Alpha-Case Formation: High-temperature processing can lead to oxygen absorption, forming a brittle alpha-case layer on the impeller surface, which must be removed mechanically post-treatment.

- Microstructural Control: Precise temperature and cooling rate control are essential to achieve the desired phase balance (e.g., alpha-beta structure in Ti-6Al-4V).

Surface Coatings

Surface coatings, such as plasma electrolytic polishing (PEP) or chemical vapor deposition (CVD), are applied to enhance hardness, corrosion resistance, and wear properties. Sandblasting is often a prerequisite to ensure proper coating adhesion.

Common Coatings:

- TiN (Titanium Nitride): Applied via CVD, increases surface hardness to 2000–2500 HV, ideal for impellers in erosive environments.

- PEP: Reduces surface roughness (Ra from 15.7 µm to 0.6 µm) and enhances corrosion resistance, suitable for medical-grade impellers.

Parameters:

- PEP Voltage: 200–400 V, with electrolyte temperatures below 100°C.

- CVD Temperature: 800–1000°C, with a deposition time of 2–4 hours.

PEP combined with sandblasting can achieve a mirror-like finish (Ra < 0.5 µm) while maintaining hardness, making it ideal for impellers requiring both aesthetic and functional properties.

Combining Sandblasting and Hardness Enhancement

Integrating sandblasting with hardness enhancement techniques creates a synergistic effect, optimizing the surface and subsurface properties of titanium alloy impellers. The process typically follows this sequence:

- Surface Preparation: Sandblasting with Al₂O₃ or ZrO₂ to clean and roughen the impeller surface, achieving Ra 1–3 µm.

- Shot Peening: Introduces compressive stresses and increases surface hardness, enhancing fatigue life.

- Heat Treatment: Refines microstructure and further increases hardness, tailored to the alloy type and application.

- Surface Coating (Optional): Applies protective layers like TiN or PEP for additional hardness and corrosion resistance.

Example Process for Ti-6Al-4V Impeller:

- Sandblast with 110 µm Al₂O₃ at 0.4 MPa, 100 mm nozzle distance, 45° angle for 10 minutes (Ra 2 µm).

- Shot peen with 0.8 mm ceramic shot at 0.4 MPa, 150% coverage to achieve 350–380 HV.

- Solution treat at 950°C for 2 hours, water quench, and age at 500°C for 6 hours to reach 360–400 HV.

- Apply TiN coating via CVD at 900°C for 3 hours to achieve 2000 HV surface hardness.

This combination enhances the impeller’s fatigue resistance, wear resistance, and coating adhesion, making it suitable for high-performance applications in aerospace or medical devices.

Applications and Performance Outcomes

The combined sandblasting and hardness enhancement process is widely applied in:

- Aerospace: Improves fatigue life and coating adhesion for turbine impellers, ensuring reliability under cyclic loading.

- Medical Devices: Enhances osseointegration and biocompatibility for implant-grade impellers, reducing wear in biological environments.

- Automotive: Increases durability of impellers in turbochargers, improving performance under high temperatures and abrasive conditions.

Performance outcomes include:

- Increased Hardness: Surface hardness improvements of 10–20% (shot peening) to 500–600% (coatings like TiN).

- Enhanced Fatigue Life: Compressive stresses from shot peening can extend fatigue life by 20–40%.

- Improved Coating Adhesion: Sandblasting increases shear strength by 50–75% for composite or coating applications.

Conclusion

Combining sandblasting and hardness enhancement techniques for titanium alloy impellers is a systematic approach to optimizing surface properties and mechanical performance. Sandblasting provides a clean, roughened surface for improved adhesion and stress induction, while hardness enhancement methods like shot peening, heat treatment, and coatings further improve durability and wear resistance. By carefully selecting abrasives, parameters, and treatment sequences, manufacturers can achieve reliable, high-performance impellers for demanding applications in aerospace, medical, and automotive industries.