Compressor impellers are critical components in industrial compressors, requiring high precision and complex geometries to ensure optimal performance. Two widely used manufacturing methods for producing these components are Electrical Discharge Machining (EDM) and grinding. This article provides a detailed comparison of their efficiency, focusing on material removal rates, surface finish, dimensional accuracy, and suitability for impeller production. The analysis is grounded in technical data and practical considerations to assist manufacturers in selecting the appropriate process.

Overview of Electrical Discharge Machining (EDM)

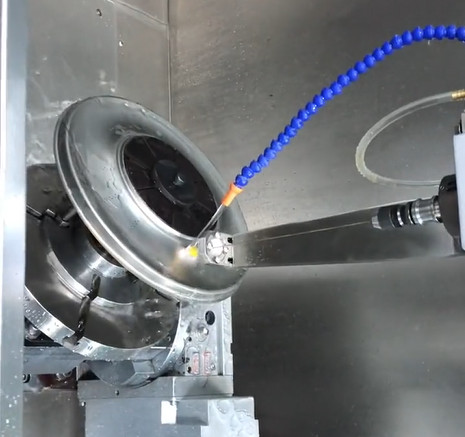

Electrical Discharge Machining (EDM) is a non-conventional machining process that uses electrical sparks to erode material from a conductive workpiece. The process involves a tool electrode and a workpiece submerged in a dielectric fluid, with rapid pulses of electricity creating sparks that vaporize and melt material. EDM is particularly effective for machining hard materials and complex geometries, such as those found in compressor impellers made from nickel alloys, titanium, or hardened steels.

EDM is categorized into subtypes, including die-sinking EDM, wire EDM, and hole-drilling EDM. For compressor impellers, die-sinking EDM is commonly used due to its ability to produce intricate cavities and twisted blade profiles. The process parameters, such as discharge current (typically 0.1–500 A), spark voltage (50–300 V), pulse duration (1–2000 µs), and inter-electrode gap (0.01–0.05 mm), significantly influence machining efficiency and surface quality. Material removal rates (MRR) in EDM typically range from 0.006–0.65 cm³/h/A, depending on the material and settings.

EDM’s non-contact nature eliminates mechanical stresses, making it ideal for delicate or thin-walled impeller structures. However, the process is slower than conventional methods, and electrode wear requires careful management to maintain dimensional accuracy.

Overview of Grinding

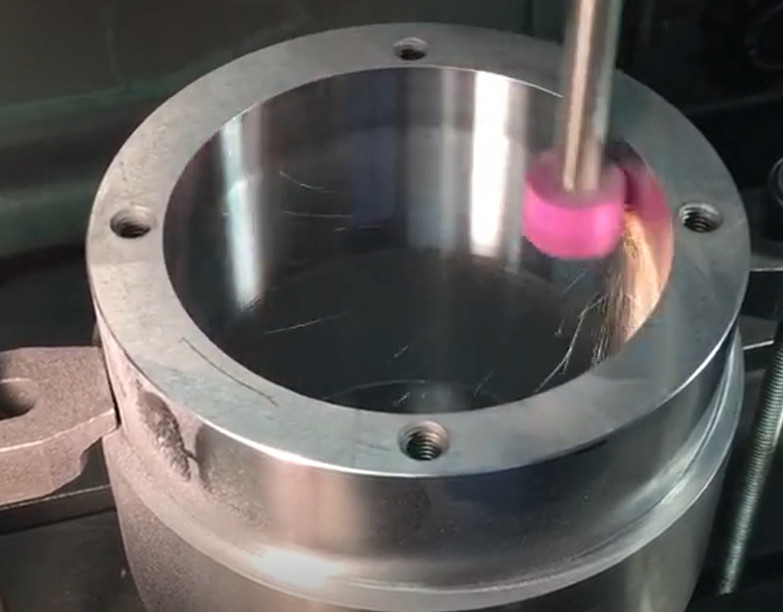

Grinding is a conventional machining process that uses abrasive wheels to remove material through mechanical forces. For compressor impellers, grinding is often employed for finishing operations to achieve high surface quality and tight tolerances. The process is versatile, capable of handling both roughing and finishing, and is commonly used for materials like stainless steel, titanium, and nickel-based alloys.

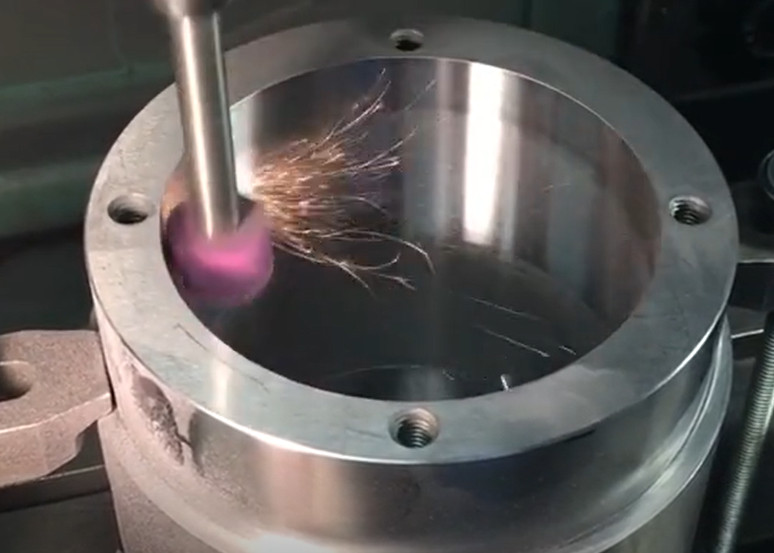

Grinding parameters include wheel speed (20–40 m/s), feed rate (0.1–2 mm/pass), and depth of cut (0.01–0.1 mm). Creep-feed grinding, a variant used for deep cuts, achieves higher MRR (1–10 cm³/min) but generates significant thermal energy, which can affect surface integrity if not properly managed. Grinding produces surface roughness values (Ra) typically between 0.3–0.8 µm, suitable for impeller applications requiring smooth airflow surfaces.

Unlike EDM, grinding involves physical contact, which can introduce mechanical stresses and potential tool wear. However, it is generally faster for material removal and widely used for its cost-effectiveness in large-scale production.

Efficiency Comparison: Material Removal Rate

Material removal rate is a key metric for evaluating machining efficiency. EDM’s MRR depends on the discharge energy, which is governed by current, voltage, and pulse duration. For example, machining nickel alloys with die-sinking EDM at a current of 10 A and pulse duration of 100 µs can achieve an MRR of approximately 0.1–0.5 cm³/h. Higher currents (e.g., 50 A) can increase MRR to 1–2 cm³/h, but this often compromises surface finish due to increased thermal effects.

Grinding, particularly creep-feed grinding, offers significantly higher MRR. For instance, grinding a titanium impeller with a wheel speed of 30 m/s and a depth of cut of 0.05 mm can achieve an MRR of 5–10 cm³/min (300–600 cm³/h). This makes grinding 100–1000 times faster than EDM in terms of material removal for large volumes. However, grinding’s efficiency decreases for complex geometries, as multiple setups and tool changes may be required to access intricate impeller features like blade cavities.

The table below summarizes the MRR for both processes when machining a typical compressor impeller material (e.g., Inconel 718):

| Process | Material Removal Rate (cm³/h) | Typical Parameters |

|---|---|---|

| EDM (Die-Sinking) | 0.1–2 | Current: 10–50 A, Pulse Duration: 50–200 µs |

| Grinding (Creep-Feed) | 300–600 | Wheel Speed: 20–40 m/s, Depth of Cut: 0.01–0.1 mm |

Surface Finish and Dimensional Accuracy

Surface finish is critical for compressor impellers, as it affects aerodynamic performance and fatigue life. EDM typically achieves surface roughness values of Ra 0.1–0.8 µm, depending on the discharge energy. Lower energy settings (e.g., 5 A, 50 µs) produce finer finishes (Ra 0.1–0.3 µm), suitable for high-precision impeller surfaces. However, EDM can create a recast layer—a thin, heat-affected zone with potential microcracks—that may require post-processing, such as polishing, to meet stringent aerospace standards.

Grinding excels in producing smooth surfaces, with Ra values as low as 0.3 µm for finish grinding. The process avoids the formation of a recast layer, but thermal effects from high grinding temperatures (up to 1000°C) can induce residual stresses or surface burns, particularly in creep-feed grinding. Proper coolant application and optimized parameters mitigate these issues.

In terms of dimensional accuracy, EDM offers superior precision for complex geometries, achieving tolerances of ±0.002–0.005 mm in wire EDM and ±0.01 mm in die-sinking EDM. Grinding achieves tolerances of ±0.01–0.02 mm, which is adequate for most impeller applications but may require additional setups for intricate features. For impellers with narrow blade tips or closed geometries, EDM’s ability to machine without physical contact provides a clear advantage.

Suitability for Compressor Impeller Geometries

Compressor impellers often feature complex, three-dimensional geometries, such as twisted blades, narrow tip widths, and deep cavities. EDM is highly suitable for these features due to its non-contact nature and ability to use custom electrodes to replicate intricate shapes. For example, die-sinking EDM can machine impeller cavities with radial slits and hollow areas, producing blades with precise profiles. A documented case involved EDM machining of turbine impellers with tolerances of ±0.01 mm, achieving consistent blade geometry without tool breakage issues common in milling.

Grinding, while effective for flat or cylindrical surfaces, faces limitations with complex impeller geometries. Accessing deep cavities or machining thin-walled blades often requires specialized fixtures or multiple grinding wheels, increasing setup time and costs. For instance, grinding a closed impeller may necessitate multiple passes with small-diameter wheels, reducing efficiency compared to EDM’s single-pass capability for such features.

Tooling and Wear Considerations

EDM requires electrodes, typically made of graphite, copper, or brass, which erode during machining. Electrode wear ratios (workpiece erosion/tool erosion) range from 0.5:1 to 100:1, depending on the material and parameters. For example, using a graphite electrode with a steel impeller at low current (5 A) can achieve a wear ratio of 10:1, minimizing the need for frequent electrode replacement. However, electrode design and wear management increase setup complexity and costs.

Grinding uses abrasive wheels, which also experience wear but at a slower rate than EDM electrodes. Wheel dressing is required periodically to maintain cutting efficiency, typically every 10–50 passes, depending on the material and grinding conditions. For high-hardness materials like Inconel, diamond or cubic boron nitride (CBN) wheels are used, which are costly but durable. Grinding’s tooling costs are generally lower than EDM’s, especially for large-scale production, but wheel wear can affect surface consistency if not monitored.

Material Compatibility

EDM is limited to electrically conductive materials, making it ideal for compressor impellers made from nickel alloys, titanium, or stainless steel. It excels in machining high-hardness materials (e.g., HRC 50–60) without inducing mechanical stresses. Grinding is more versatile, capable of machining both conductive and non-conductive materials, though it is less effective for very hard materials due to increased wheel wear and thermal effects.

For compressor impellers, both processes are commonly used for materials like Inconel 718 or titanium alloys. EDM’s ability to machine without physical contact reduces the risk of deformation in thin-walled structures, while grinding’s high MRR is advantageous for roughing operations on larger impeller components.

Cost and Production Time

EDM is generally more expensive due to its slower MRR and the need for custom electrodes. Machining a single impeller cavity with die-sinking EDM may take 10–20 hours, depending on the geometry and material. Electrode fabrication and setup can add 5–10 hours to the process. Grinding, in contrast, is faster, with roughing operations taking 1–2 hours for similar components. However, complex impeller geometries may require multiple grinding setups, increasing total production time.

Cost comparisons depend on production volume. For low-volume, high-precision impellers, EDM’s ability to produce complex shapes in a single setup often justifies its higher cost. For high-volume production, grinding’s speed and lower tooling costs make it more economical, provided the geometry is accessible.

Practical Considerations for Compressor Impeller Manufacturing

Choosing between EDM and grinding depends on the specific requirements of the compressor impeller. EDM is preferred for impellers with intricate geometries, such as closed or deep cavities, where grinding tools cannot easily access. It also offers advantages for small-batch production or prototyping, where precision and minimal mechanical stress are critical. Grinding is better suited for high-volume production or simpler geometries, where its high MRR and lower tooling costs provide economic benefits.

Hybrid approaches, such as using EDM for roughing complex features and grinding for finishing, are sometimes employed to balance efficiency and quality. For example, EDM can shape the impeller’s blade cavities, followed by grinding to achieve the desired surface finish (Ra 0.3–0.5 µm).

Conclusion

Electrical Discharge Machining and grinding each offer distinct advantages for compressor impeller manufacturing. EDM excels in machining complex geometries and hard materials with high precision, albeit at a slower rate and higher cost. Grinding provides superior material removal rates and is more cost-effective for simpler geometries and high-volume production, but it struggles with intricate features. Manufacturers must weigh factors such as geometry complexity, material properties, production volume, and cost to select the optimal process. In practice, a combination of both methods may be used to achieve the desired balance of efficiency, precision, and surface quality.