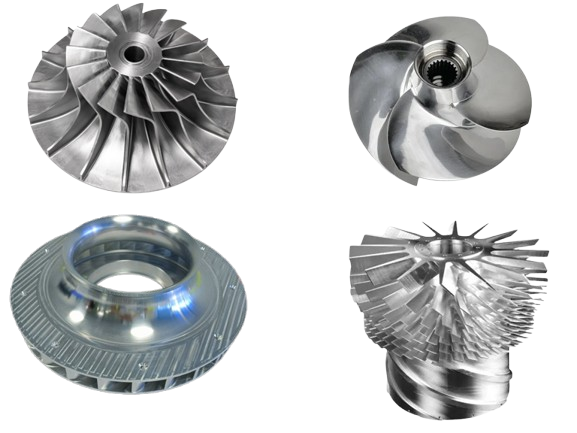

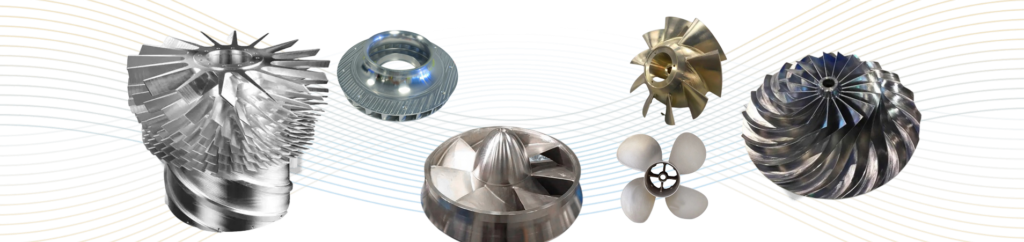

Custom impeller machining is a precision manufacturing process that produces tailored impellers for critical applications in industries such as marine, aerospace, industrial pumping, and energy. These rotating components, essential for pumps, turbines, and propulsion systems, require meticulous design and fabrication to achieve optimal performance. This article delves into the intricacies of custom impeller machining, focusing on cost considerations, factory selection, and the scope of customization. With detailed parameters and practical insights, this guide is designed for engineers, procurement professionals, and businesses seeking high-quality impellers.

Understanding Custom Impeller Machining

Impellers are rotating components that transfer energy to fluids, driving flow in systems like water pumps, jet engines, or industrial turbines. Custom impeller machining uses advanced CNC (Computer Numerical Control) technology to fabricate impellers to exact specifications, accommodating unique geometries, materials, and performance requirements. Unlike standard impellers, custom solutions allow for precise tailoring to applications, ensuring efficiency, durability, and compatibility.

The process typically involves:

- Design Input: Customers provide 2D drawings, 3D CAD models, or physical samples.

- Material Selection: Choosing materials like stainless steel, aluminum, or titanium based on application needs.

- CNC Machining: Using 3-axis, 4-axis, or 5-axis CNC machines to shape the impeller.

- Finishing: Polishing, coating, or balancing to enhance performance.

- Quality Control: Inspecting tolerances, balance, and material integrity.

This article explores how cost, factory capabilities, and customization scope shape the success of custom impeller machining projects.

Cost Factors in Custom Impeller Machining

Cost is a critical consideration in custom impeller machining, influenced by material selection, design complexity, precision requirements, and production volume. Understanding these factors helps businesses optimize budgets while maintaining quality.

Material Costs

The choice of material significantly impacts the cost of custom impeller machining. Common materials include:

- Stainless Steel (e.g., 316L): Offers corrosion resistance and durability for marine and industrial pumps. Cost: $5-$15 per kg. Density: 8.0 g/cm³. Tensile Strength: ~550 MPa.

- Aluminum (e.g., 6061-T6): Lightweight and cost-effective for less demanding applications. Cost: $2-$5 per kg. Density: 2.7 g/cm³. Tensile Strength: ~310 MPa.

- Titanium (e.g., Ti-6Al-4V): High strength-to-weight ratio and corrosion resistance for aerospace and high-performance systems. Cost: $30-$50 per kg. Density: 4.43 g/cm³. Tensile Strength: ~900 MPa.

- Bronze (e.g., C95400): Excellent for water-based systems due to corrosion resistance. Cost: $10-$20 per kg. Density: 7.45 g/cm³. Tensile Strength: ~550 MPa.

Material costs vary based on market prices, availability, and machining difficulty. For example, titanium’s high cost is justified in aerospace applications requiring low weight and high strength, while aluminum suits budget-conscious marine projects.

Design Complexity and Machining Time

The complexity of an impeller’s design directly affects machining costs. Key parameters include:

- Blade Geometry: Impellers with intricate blade profiles (e.g., curved or variable-pitch blades) require 5-axis CNC machines, increasing machining time. A complex 6-blade impeller may take 10-20 hours to machine.

- Tolerances: Tight tolerances (e.g., ±0.0005 inches or ±0.0127 mm) demand high-precision equipment and skilled operators. Standard tolerances (±0.005 inches) are less costly.

- Surface Finish: Requirements like Ra 0.8 µm (mirror finish) add post-processing time, increasing costs by 10-20%.

CNC machining rates typically range from $60-$200 per hour, depending on equipment and location. A simple impeller may cost $500-$1,500, while a complex aerospace impeller could exceed $5,000.

Production Volume

Production volume significantly influences per-unit costs:

- Prototyping: Single-unit or small-batch (1-10 units) production incurs high setup and programming costs. Cost per impeller: $500-$5,000.

- Low-Volume Production: 10-100 units benefit from shared setup costs. Cost per impeller: $200-$1,500.

- High-Volume Production: 1,000+ units leverage economies of scale. Cost per impeller: $50-$500.

Businesses can reduce costs by planning for bulk production or using rapid prototyping to validate designs before scaling.

Additional Cost Factors

Other expenses include:

- Tooling: Custom tools for unique designs may cost $100-$1,000.

- Lead Time: Rush orders (e.g., 1-2 day prototypes) may incur 20-50% premiums.

- Quality Assurance: Testing for balance (e.g., ISO 1940 G2.5), vibration, or material certification adds $50-$500 per unit.

- Shipping: International shipping for overseas factories may add $50-$500, depending on weight and urgency.

To optimize costs, businesses should:

- Use design-for-manufacturability (DFM) principles to simplify geometries.

- Select materials that balance performance and budget.

- Request quotes from multiple factories to compare pricing.

- Plan production schedules to avoid rush fees.

Factory Selection for CNC Impeller Machining

Choosing the right factory is critical to achieving high-quality impellers that meet specifications and deadlines. A capable factory combines advanced equipment, certifications, and industry expertise to deliver reliable results.

Equipment Capabilities

The factory’s CNC equipment determines its ability to handle complex impeller designs. Key machines include:

- 3-Axis CNC Mills: Suitable for simple impellers with basic geometries. Work envelope: ~1,000 x 500 x 500 mm. Spindle speed: 10,000 RPM.

- 5-Axis CNC Mills: Essential for complex, multi-dimensional impellers with curved blades. Work envelope: ~800 x 600 x 500 mm. Spindle speed: 20,000 RPM.

- CNC Lathes: Used for symmetrical components or finishing operations. Max diameter: ~500 mm.

Factories with 5-axis machines and high-speed spindles are ideal for aerospace or high-performance impellers requiring tight tolerances (e.g., ±0.01 mm).

Certifications and Standards

Certifications ensure quality and compliance with industry standards:

- ISO 9001: Guarantees consistent quality management processes.

- AS9100: Critical for aerospace applications, ensuring stringent quality and traceability.

- ISO 13485: Relevant for medical-grade impellers in healthcare devices.

Factories with these certifications are better equipped to meet regulatory requirements, reducing the risk of defects or non-compliance.

Experience and Specialization

A factory’s track record is a key indicator of reliability:

- Industry Expertise: Factories with experience in marine, aerospace, or industrial pumps understand specific material and design needs.

- Portfolio: A history of producing similar impellers demonstrates capability.

- Engineering Support: Factories offering DFM feedback or CFD (Computational Fluid Dynamics) analysis can optimize designs for cost and performance.

For example, a factory specializing in marine impellers may recommend bronze for corrosion resistance, while an aerospace-focused factory may suggest titanium for weight savings.

Production Capacity and Lead Time

Evaluate the factory’s ability to meet your timeline and volume needs:

- Prototyping: Factories with rapid prototyping capabilities can deliver samples in 1-3 days.

- Low-Volume Production: 10-100 units typically require 1-2 weeks.

- High-Volume Production: 1,000+ units may take 4-8 weeks, depending on capacity.

Factories with multiple CNC machines and automated workflows can handle large orders without delays. Geographic location also matters—local factories offer faster shipping, while overseas factories (e.g., in China) may provide lower costs for bulk production.

Quality Control and Communication

Reliable factories prioritize quality and transparency:

- Quality Assurance: In-process inspections, CMM (Coordinate Measuring Machine) checks, and balance testing (e.g., ISO 1940 G2.5) ensure precision.

- Material Certification: Providing mill certificates for materials like titanium or stainless steel ensures traceability.

- Communication: Clear updates on production status and responsive customer support are essential for complex projects.

Factories with robust quality control reduce the risk of defects, while effective communication ensures alignment on specifications.

Customization Scope in Impeller Machining

The ability to customize impellers is the hallmark of custom machining, enabling businesses to create components that precisely match their system’s needs. The scope of customization spans design, materials, precision, and production volume.

Design Flexibility

Custom impeller machining supports a wide range of design possibilities:

- Geometry: Blade shapes (e.g., straight, curved, or variable-pitch), blade counts (4-12 blades), and hub designs tailored to fluid dynamics. Example: A centrifugal impeller may have 6 curved blades for high-pressure pumps.

- Sizes: Impellers ranging from 10 mm (for medical pumps) to 1,000 mm (for industrial turbines).

- Types: Centrifugal (radial flow), axial-flow (propeller-like), or mixed-flow impellers, each optimized for specific applications.

Customers can submit 3D CAD files (e.g., STEP or IGES formats) or physical samples, and factories will adapt the design to meet performance goals, such as maximizing flow rate (e.g., 500 L/min) or pressure (e.g., 10 bar).

Material Options

Material selection is critical to impeller performance and durability:

- Stainless Steel: Ideal for corrosive environments like seawater. Example: 316L for marine pumps operating at 50°C.

- Aluminum: Lightweight for energy-efficient systems. Example: 6061-T6 for marine impellers at 3,000 RPM.

- Titanium: High strength for aerospace turbines operating at 10,000 RPM and 200°C.

- Bronze: Corrosion-resistant for water pumps with flow rates up to 1,000 L/min.

- Polymers/Composites: Lightweight and cost-effective for low-pressure systems (e.g., HVAC pumps).

Factories may conduct material testing (e.g., hardness or corrosion tests) to ensure suitability for specific conditions.

Precision and Tolerances

Custom machining achieves high precision to meet demanding requirements:

- Tolerances: As tight as ±0.0005 inches (±0.0127 mm) for aerospace or medical applications.

- Surface Finish: Ra 0.4-1.6 µm for reduced drag and improved efficiency.

- Balance: Dynamic balancing to ISO 1940 G2.5 for minimal vibration at high speeds (e.g., 20,000 RPM).

These capabilities ensure impellers perform reliably in high-stakes applications, such as jet engines or industrial compressors.

Production Range

Custom machining supports a wide range of production volumes:

- Prototyping: 1-10 units for design validation. Lead time: 1-3 days.

- Low-Volume Production: 10-100 units for niche applications. Lead time: 1-2 weeks.

- High-Volume Production: 1,000+ units for OEMs. Lead time: 4-8 weeks.

Factories can scale processes to maintain consistency across batches, using automated CNC workflows for efficiency.

Application-Specific Features

Customization addresses specific operational needs:

- Marine: Corrosion-resistant bronze impellers for seawater pumps with flow rates of 500-2,000 L/min.

- Aerospace: Titanium impellers with ±0.01 mm tolerances for turbines operating at 200°C and 15,000 RPM.

- Industrial: Stainless steel impellers for chemical pumps handling pressures up to 20 bar.

- Medical: Biocompatible polymer impellers for precision pumps in dialysis machines.

Factories may use CFD simulations to optimize blade designs for specific flow characteristics, ensuring peak performance.

Best Practices for Successful Custom Impeller Machining

To maximize the benefits of custom impeller machining, businesses should follow these best practices:

- Define Specifications Clearly: Provide detailed CAD files, material requirements, and performance goals (e.g., flow rate, pressure, or operating temperature).

- Collaborate with Factories: Work with the factory’s engineering team to refine designs and select materials.

- Use Prototyping: Test prototypes to validate performance before committing to large-scale production.

- Optimize for Cost: Apply DFM principles to simplify designs and reduce machining time.

- Verify Quality: Request material certifications, inspection reports, and balance test results.

- Plan Production: Align production schedules with project timelines to avoid rush fees.

By adhering to these practices, businesses can achieve high-quality impellers that meet performance and budget goals.

Conclusion

Custom impeller machining offers unparalleled flexibility to create high-performance components for marine, aerospace, industrial, and medical applications. By carefully managing costs through material selection, design optimization, and production planning, businesses can achieve cost-effective solutions. Selecting a factory with advanced CNC equipment, certifications, and industry expertise ensures precision and reliability. The expansive customization scope allows for tailored designs, materials, and production volumes, enabling impellers that meet exact performance requirements.

To succeed, businesses should define clear specifications, collaborate with factories, and leverage prototyping to validate designs. With the right approach, custom impeller machining delivers components that enhance efficiency, durability, and system performance.

Frequently Asked Questions (FAQ)

What is custom impeller machining?

Custom impeller machining is the process of manufacturing impellers to specific designs using CNC machines. It allows for tailored geometries, materials, and tolerances to meet unique application needs in industries like marine, aerospace, and industrial pumping.

How much does custom impeller machining cost?

Costs vary based on material, complexity, tolerances, and volume. Prototypes may cost $500-$5,000 per unit, while high-volume production can reduce costs to $50-$500 per unit. Request quotes from factories for accurate pricing.

What materials are used in custom impeller machining?

Common materials include stainless steel (e.g., 316L), aluminum (e.g., 6061-T6), titanium (e.g., Ti-6Al-4V), bronze (e.g., C95400), and polymers. The choice depends on the application, such as corrosion resistance for marine or lightweight strength for aerospace.

How do I choose a factory for custom impeller machining?

Select a factory with advanced CNC equipment (e.g., 5-axis mills), relevant certifications (e.g., ISO 9001, AS9100), and experience in your industry. Verify production capacity, quality control processes, and communication responsiveness.

What is the lead time for custom impellers?

Prototypes typically take 1-3 days, low-volume production (10-100 units) takes 1-2 weeks, and high-volume production (1,000+ units) may take 4-8 weeks, depending on complexity and factory capacity.