A detailed exploration of grinding processes, tools, and precision techniques used in modern manufacturing to achieve high accuracy and surface quality.

Definition and Principles of Grinding

Grinding is an abrasive machining process that uses a grinding wheel as a cutting tool to remove material from a workpiece, achieving precise dimensions and smooth surface finishes. Each abrasive grain on the wheel acts as a microscopic cutting tool, shearing small chips from the workpiece surface. This process is particularly effective for hard materials like metals, ceramics, and composites, where other machining methods may be less efficient.

The grinding process relies on the interaction between the abrasive wheel, the workpiece, and the machine tool. Key parameters include wheel speed (typically 2000–6500 fpm or 10–33 m/s), workpiece feed rate, depth of cut (0.25–0.50 mm for roughing, 200 nm for finishing), and coolant application to manage heat. The wheel’s abrasive grains, bonded by materials like vitrified clay or resin, determine cutting efficiency and surface quality.

Grinding is often a finishing operation due to its ability to achieve tolerances as tight as ±0.00005 inches (1.3 μm) for diameter and ±0.00001 inches (0.25 μm) for roundness, with surface finishes ranging from 2 to 32 microinches (0.05–0.81 μm). It is widely used in industries requiring high precision, such as aerospace, automotive, and tool manufacturing.

Types of Grinding Processes

Grinding processes vary based on the workpiece geometry, required precision, and material removal rate. The following are the primary types used in manufacturing:

- Surface Grinding: Produces flat surfaces using a rotating abrasive wheel. The workpiece is held on a reciprocating table or magnetic chuck. Tolerances are typically ±0.0002 inches (5.1 μm) for flatness and ±0.0003 inches (7.6 μm) for parallelism. Surface finishes range from 8 to 32 microinches (0.20–0.81 μm). Common applications include mold bases and machine beds.

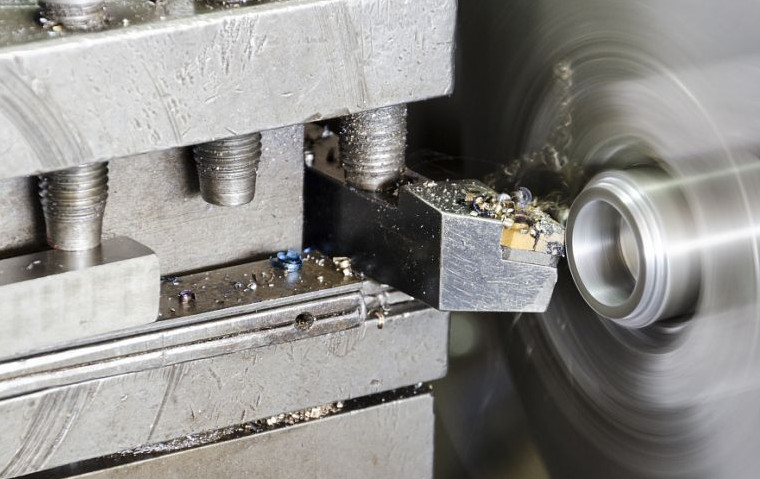

- Cylindrical Grinding: Shapes cylindrical or conical surfaces by rotating the workpiece and feeding it past a grinding wheel. Tolerances can reach ±0.00005 inches (1.3 μm) for diameter and ±0.00001 inches (0.25 μm) for roundness. It is used for precision rods, bearings, and shafts.

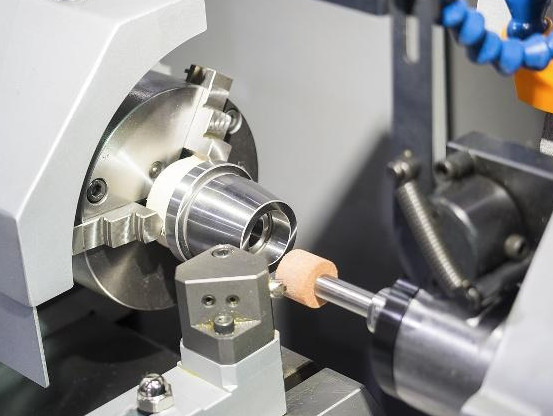

- Internal Grinding: Grinds internal surfaces, such as bores, using small-diameter wheels. Boron carbide wheels are effective for hard materials, achieving tolerances of ±0.0001 inches (2.5 μm). Applications include bushings and engine cylinders.

- Centerless Grinding: Supports the workpiece between a regulating wheel and a grinding wheel, eliminating the need for centers. It achieves high throughput with tolerances of ±0.0001 inches (2.5 μm). Common for mass-produced pins and rollers.

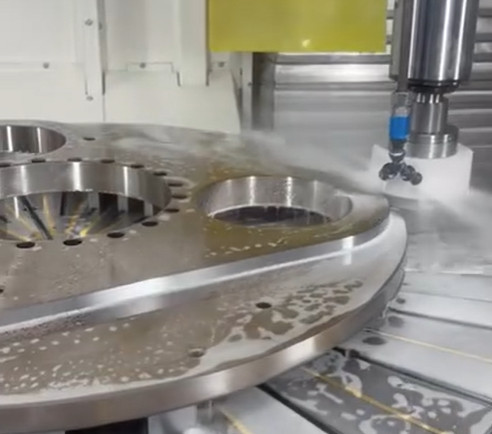

- Creep-Feed Grinding (CFG): Removes large volumes of material in a single pass with slow feed rates. It requires high spindle power (up to 51 hp or 38 kW) and continuous wheel dressing. Material removal rates can reach 1 in³ (16 cm³) in 17 seconds with continuous-dress CFG.

Each process is selected based on workpiece material, geometry, and production requirements. For example, surface grinding is ideal for flat components, while cylindrical grinding suits rotational parts.

Grinding Tools and Equipment

Grinding tools and machines are critical to achieving desired outcomes. The primary tool is the grinding wheel, composed of abrasive grains, a bonding matrix, and pores. Other equipment includes machine tools, workholding devices, and coolant systems.

Grinding Wheels

Grinding wheels are defined by five characteristics:

| Characteristic | Description | Typical Values |

|---|---|---|

| Abrasive Material | Determines cutting ability. Common materials include aluminum oxide (for steel), silicon carbide (for cast iron), and superabrasives like diamond (for ceramics) or CBN (for hard steels). | Aluminum oxide, silicon carbide, diamond, CBN |

| Grain Size | Affects surface finish and cutting speed. Coarse grains (10–24) for roughing; fine grains (220–600) for finishing. | 10–600 |

| Wheel Grade | Indicates bond strength, from A (soft) to Z (hard). Soft grades for hard materials; hard grades for soft materials. | A–Z |

| Grain Spacing | Density of abrasives, from 1 (dense) to 17 (open). Open structures for soft materials or high stock removal. | 1–17 |

| Bond Type | Holds abrasives together. Vitrified bonds for precision; resin bonds for high-speed operations. | Vitrified, resin, metal |

Wheel selection depends on the workpiece material and desired finish. For example, aluminum oxide wheels are versatile for steel alloys, while diamond wheels are preferred for ceramics.

Grinding Machines

Modern grinding machines incorporate CNC systems for automation and precision. Common types include:

- Bench Grinders: Portable or stationary tools for small-scale sharpening or deburring.

- Cylindrical Grinders: Equipped with multiple wheels for external or internal grinding of cylindrical parts.

- Surface Grinders: Feature a reciprocating table and magnetic or vacuum chuck for flat surface finishing.

- Centerless Grinders: Designed for high-volume production with automated feed systems.

Machines are equipped with coolant systems to dissipate heat, dressers to maintain wheel sharpness, and control panels for adjusting parameters like speed and feed rate.

Precision Techniques in Grinding

Precision grinding requires meticulous control of process parameters and techniques to achieve tight tolerances and superior surface finishes. Key techniques include:

Wheel Dressing and Truing

Dressing removes dull grains and exposes fresh abrasives, while truing ensures the wheel runs concentric to its axis. Continuous-dress creep-feed grinding (CDCF) maintains wheel sharpness during machining, reducing cycle time to 17 seconds for removing 1 in³ (16 cm³) of material. Electrolytic in-process dressing (ELID) uses electrochemical reactions to dress metal-bonded wheels, achieving ultra-precision tolerances of ±0.00001 inches (0.25 μm).

Coolant Application

Grinding generates significant heat, which can cause thermal damage or dimensional inaccuracies. Coolants, typically water-based with additives, are delivered via nozzles at the grinding zone. For ultra-precision grinding, minimal coolant is used, as heat generation is negligible at depths of 200 nm per pass. Alkaline electrolytes are used in ELID grinding to serve as both coolant and dressing medium.

Parameter Optimization

Optimizing parameters like wheel speed, feed rate, and depth of cut is critical. For example, high-efficiency deep grinding (HEDG) uses plated superabrasive wheels at speeds up to 6500 fpm (33 m/s) to achieve high removal rates with low thermal impact. Typical parameters for precision grinding include:

| Parameter | Rough Grinding | Precision Grinding |

|---|---|---|

| Wheel Speed (fpm) | 2000–4000 | 4000–6500 |

| Depth of Cut (mm) | 0.25–0.50 | 0.0002–0.005 |

| Feed Rate (mm/min) | 100–500 | 10–50 |

| Surface Finish (microinches) | 32–125 | 2–32 |

Workholding and Fixturing

Stable workholding ensures repeatability. Magnetic chucks are common for ferrous materials, while vacuum chucks suit non-magnetic workpieces. In centerless grinding, the regulating wheel and support blade maintain workpiece stability without fixturing.

Applications of Grinding in Manufacturing

Grinding is integral to industries requiring high precision and surface quality. Key applications include:

- Aerospace: Grinding turbine blades, landing gear, and fuel nozzles to tolerances of ±0.0001 inches (2.5 μm) with mirror-like finishes.

- Automotive: Producing engine components, gears, and bearings with precise profiles for efficiency and durability.

- Tool and Die: Sharpening cutting tools and shaping dies to maintain tight tolerances and edge quality.

- Medical: Manufacturing surgical instruments and implants with biocompatible finishes and accuracies of ±0.00005 inches (1.3 μm).

Grinding’s versatility extends to materials like steel, aluminum, ceramics, and composites, making it indispensable for high-precision manufacturing.

Quality Control in Grinding

Quality control ensures grinding meets design specifications. Techniques include:

- Dimensional Inspection: Using micrometers and gauges to verify tolerances.

- Surface Roughness Testing: Profilometers measure finishes to ensure compliance with standards like 8–32 microinches (0.20–0.81 μm).

- In-Process Gauging: Real-time monitoring adjusts parameters to maintain consistency.

- Statistical Process Control (SPC): Analyzes data to detect deviations and optimize processes.

These methods ensure reliability and repeatability, critical for industries like aerospace and medical manufacturing.

Conclusion

Grinding is a cornerstone of precision manufacturing, offering unmatched accuracy and surface quality for a wide range of materials and applications. By understanding its principles, selecting appropriate tools, and applying precision techniques, manufacturers can achieve tolerances as tight as ±0.00001 inches (0.25 μm) and finishes as fine as 2 microinches (0.05 μm). With robust quality control and optimized parameters, grinding remains a reliable and systematic process for producing high-performance components across industries.