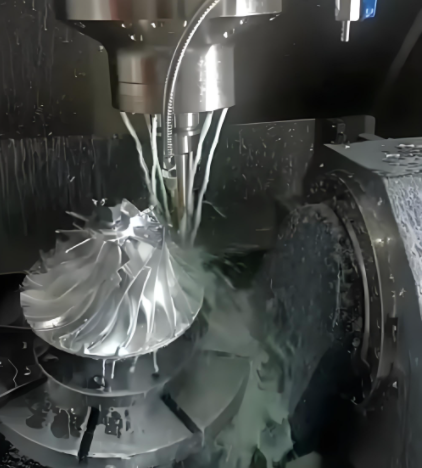

High-temperature alloys, as critical materials capable of withstanding complex stresses over long periods in high-temperature environments with excellent oxidation and corrosion resistance, are widely used in core industrial sectors such as aerospace, energy, automotive, and chemical engineering. Core components of high-performance equipment like gas turbines, aero-engines, and nuclear power plant equipment, such as turbine impellers, combustion chambers, and fasteners, are inseparable from high-temperature alloys. However, it is precisely their outstanding performance at high temperatures that makes high-temperature alloys notoriously difficult to machine at room temperature, earning them the reputation as a "tough bone" in manufacturing.

To achieve efficient and precise machining of high-temperature alloys, it is necessary to deeply understand the challenges posed by their unique material properties and adopt targeted processes and technologies.

Machining Difficulties: Tool Wear, Work Hardening, and Heat Dissipation

The poor machinability of high-temperature alloys primarily stems from the following aspects:

- Severe Tool Wear:

- High Strength at High Temperatures: High-temperature alloys possess high strength and hardness even at room temperature, requiring significant cutting forces during machining.

- Good High-Temperature Stability: High-temperature alloys maintain high strength even under the high temperatures generated during cutting, causing severe friction and wear on the tool rake face.

- Hard Points in Microstructure: The alloys often contain hard points such as carbides, nitrides, or intermetallic compounds formed by elements like Ti, Cr, Mo, W, which cause strong abrasive wear on the tool.

- Strong Chemical Affinity: High-temperature alloys are prone to chemical reactions or diffusion wear with tool materials at high temperatures, forming crater wear (rake face wear) and flank wear.

- Significant Work Hardening:

- Under the action of cutting forces, the metal in the cutting zone of high-temperature alloys undergoes rapid plastic deformation, causing a sharp increase in the hardness of the surface layer material.

- The work-hardened layer is hard and deep, making subsequent cutting even more difficult. The tool needs to cut below the hardened layer, increasing cutting forces and tool load, further exacerbating tool wear and material hardening, creating a vicious cycle.

- Extremely Poor Heat Dissipation:

- High-temperature alloys have very poor thermal conductivity. The vast amount of heat generated during the cutting process cannot be quickly dissipated through the workpiece or chips. Instead, it is highly concentrated in the cutting zone and at the tool tip.

- This localized extreme heat accelerates the softening, chemical reaction, and diffusion of the tool material, leading to a drastic reduction in tool life. Simultaneously, high temperatures can also adversely affect the surface properties of the workpiece.

Key Machining Processes for High-Temperature Alloys: Turning, Milling, and Drilling

Addressing the above difficulties requires adopting optimized machining processes and strategies:

- Turning:

- Use lower cutting speeds to control cutting temperature and reduce chemical wear.

- Select a larger feed rate and appropriate depth of cut to ensure the tool cuts below the work-hardened layer, avoiding repeated cutting on the hardened surface.

- The tool rake angle can be appropriately reduced or even negative to increase tool strength, but the issue of increased cutting force must be balanced; the clearance angle should be large enough to reduce friction.

- Ensure the machine tool system has sufficient rigidity and power to avoid vibration.

- Milling:

- Conventional milling and climb milling are common. For high-temperature alloys, climb milling is usually recommended because the tool enters the workpiece at the maximum chip thickness, which reduces the contact time between the tool and the work-hardened layer and helps carry heat away with the chips.

- Control impact during tool entry and exit, strategies such as helical or ramped entry can be adopted.

- Different cutting strategies like large depth of cut with small feed, or small depth of cut with large feed, can be combined.

- Drilling:

- Drilling is one of the most difficult machining processes for high-temperature alloys due to the confined cutting area, poor heat dissipation, and difficult chip evacuation.

- Specially designed drills are required, such as those with specific flute geometry, high-strength substrates, and heat-resistant coatings.

- Adopt appropriate cutting speeds and feed rates to avoid the formation of built-up edge.

- Forced cooling and chip evacuation are crucial, often requiring internal coolant drills combined with high-pressure cutting fluid.

- Stepped drilling or peck drilling can help break chips and facilitate cooling.

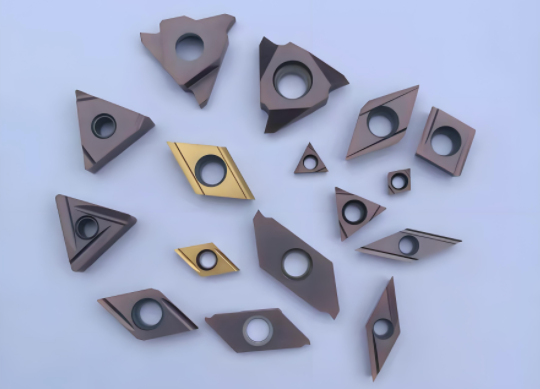

Application and Selection of Cutting Tools in High-Temperature Alloy Machining

Cutting tools are key to successful high-temperature alloy machining. Tool material, geometry, and coating all require careful selection:

- Tool Materials:

- Carbide: Commonly used, but requires selecting fine-grain, high-cobalt content, and high-toughness grades. It is the basis for most machining operations.

- Ceramic Tools: Suitable for high-speed roughing of some high-temperature alloys, especially nickel-based alloys. They have extremely high hardness and heat resistance but are very brittle and highly sensitive to machine rigidity and process stability, not suitable for interrupted cutting.

- PCBN (Polycrystalline Cubic Boron Nitride) Tools: Possess extremely high hardness and wear resistance, particularly suitable for finishing and semi-finishing of hardened steel and nickel-based high-temperature alloys, enabling turning instead of grinding. They are expensive and relatively brittle.

- Tool Geometry:

- Requires a sharp cutting edge to reduce cutting forces but also sufficient strength to resist chipping.

- Appropriate positive rake angle (if the tool material allows) or a small negative rake angle.

- A larger clearance angle to reduce friction.

- Designed chip grooves and chip breakers.

- Edge preparation (honing or chamfering) is performed to increase edge strength.

- Tool Coatings:

- PVD or CVD coatings, such as TiAlN, AlTiN, etc., can significantly improve tool hardness, wear resistance, heat resistance, and reduce the affinity between the tool and workpiece material, extending tool life.

High-Efficiency and Precision Machining Technology for High-Temperature Alloys

Achieving high efficiency and precision in high-temperature alloy machining requires integrating more technologies beyond the basic processes and tool selection discussed above:

- Optimization of Cutting Parameters: Through extensive experiments and data analysis, determine the optimal combination of cutting speed, feed rate, and depth of cut to balance tool life, machining efficiency, and surface quality.

- High-Rigidity Machine Tools and Fixtures: High-temperature alloy machining involves large cutting forces, requiring machine tool and fixturing systems with high rigidity, good damping performance, and sufficient power to ensure process stability, reduce vibration, and improve accuracy.

- Online Monitoring and Intelligent Control: Utilize sensors to monitor parameters such as cutting force, vibration, and temperature, combined with artificial intelligence algorithms for real-time analysis and adjustment, optimizing the cutting process and predicting tool life.

- Process Simulation: Use methods like finite element analysis to simulate the cutting process, predict cutting forces, temperature distribution, stress distribution, and tool wear, guiding the selection and optimization of process parameters.

- Hybrid Machining Technologies: Combine multiple machining methods, such as turn-milling, electrical discharge milling, ultrasonic-assisted machining, etc., to leverage the advantages of different technologies and improve machining efficiency and precision.

Selection of Cutting Fluids and Cooling Strategies in High-Temperature Alloy Machining

Cutting fluids play a crucial role in high-temperature alloy machining, with their main functions being cooling, lubrication, and chip evacuation.

- Selection of Cutting Fluid: Cutting fluids with good cooling and lubricating properties must be selected. Common types include:

- Emulsions: Economical and practical, with relatively good cooling performance but poorer lubrication.

- Semi-synthetic or Fully Synthetic Cutting Fluids: More balanced in lubrication and cooling, usually containing more extreme pressure additives, making them more suitable for high-temperature alloy machining.

- Neat Oils: Provide the best lubrication but lack sufficient cooling effect at high cutting speeds and are prone to generating oil mist, less widely used in high-speed cutting.

- Cooling Strategies:

- Sufficient Flood Cooling: Ensure the cutting fluid adequately reaches the cutting zone, carries away heat, and lubricates the contact surfaces between the tool and workpiece.

- High-Pressure Cooling: Using a high-pressure (tens or even hundreds of MPa) cutting fluid jet can more effectively penetrate the cutting zone, carry away heat and chips, and even help control built-up edge and reduce tool wear.

- MQL (Minimum Quantity Lubrication): Spraying a very small amount of cutting fluid mixed with compressed air into the cutting zone aims to reduce cutting fluid consumption while providing some lubrication and cooling effect, but the cooling effect is not as good as flood cooling.

- Cryogenic Cooling: Using cryogenic media like liquid nitrogen for cooling can significantly reduce the cutting zone temperature, improve tool hardness and life, but requires high equipment costs and complex operation.

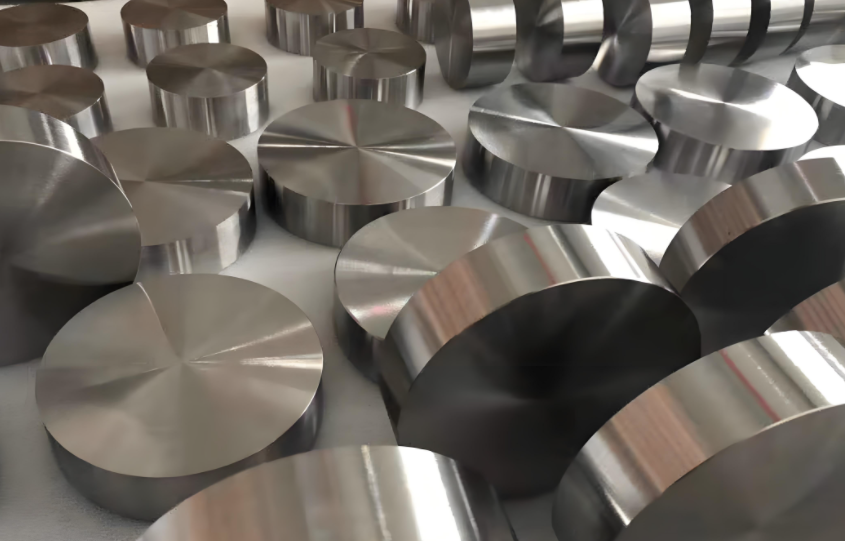

Machinability Comparison of Different Types of High-Temperature Alloys

High-temperature alloys are not a single material; their composition, microstructure, and heat treatment state vary greatly, leading to differences in machinability:

- Nickel-Based High-Temperature Alloys: Such as Inconel, Waspaloy, etc., are usually the most difficult to machine, especially after age hardening. They have a high tendency for work hardening and extremely high strength and hardness at high temperatures.

- Cobalt-Based High-Temperature Alloys: Such as the Stellite series, often contain a large number of hard carbides, which cause severe abrasive wear on tools, making them also very difficult to machine.

- Iron-Based High-Temperature Alloys: Such as some special heat-resistant stainless steels or alloys, are generally slightly easier to machine than nickel-based and cobalt-based alloys, but still far more challenging than standard steels.

Therefore, when selecting machining processes and parameters, it is essential to specifically analyze the grade and state of the high-temperature alloy being machined.

KeSu High-Temperature Alloy Machining Service

The complexity of high-temperature alloys demands exceptional processing. If you are seeking a partner capable of working with these special materials and ensuring the performance and reliability of your final products, we possess the capabilities you need.

With extensive experience and precision equipment in the field of high-temperature alloy processing, KeSu provides stable and reliable manufacturing services. We meet the stringent standards for components operating in extreme high-temperature environments across industries such as aerospace, energy, and petrochemicals. We focus on detail, ensuring every product meets design requirements.

Conclusion

Machining of high-temperature alloys is a critical technical challenge in the field of modern high-end manufacturing. Severe tool wear, significant work hardening, and extremely poor heat dissipation are the main difficulties. To overcome these challenges, it is necessary to comprehensively utilize advanced tooling technology (material, coating, geometry), optimize cutting parameters, adopt effective cooling and lubrication strategies, and rely on highly rigid machine tool equipment and precise process control.

With the development of new materials, new tools, new equipment, and intelligent manufacturing technologies, the ability for efficient and precise machining of high-temperature alloys is continuously improving, providing strong support for the development of key fields such as aerospace and energy.

FAQ

What are high-temperature alloys?

High-temperature alloys are special metallic materials that maintain excellent strength, corrosion resistance, and oxidation resistance even at very high temperatures. They are primarily used in critical components operating in severe environments with high temperature, high pressure, or strong corrosion, such as aero-engines, gas turbines, nuclear power plants, and petrochemical equipment.

Why are high-temperature alloys considered difficult to machine?

The difficulty in machining high-temperature alloys is mainly because they retain high strength during cutting, are prone to work hardening (becoming harder as they are cut), and have poor thermal conductivity, which concentrates cutting heat on the tool and rapidly accelerates tool wear.

Why does tool wear occur severely when machining high-temperature alloys?

The main reasons are the material's inherent high hardness and hard points, which cause abrasive wear on the tool; additionally, high-temperature alloys and tool materials are prone to chemical reactions and diffusion at cutting temperatures, intensifying tool wear. Work hardening also increases the cutting load on the tool.

What kind of special tools are needed for machining high-temperature alloys?

Specialized tools designed for high-temperature alloys are required. These typically use high-performance materials like cemented carbide, ceramics, or PCBN (Polycrystalline Cubic Boron Nitride), combined with special geometries and heat-resistant, wear-resistant coatings.

What are the important roles of cutting fluid in high-temperature alloy machining?

Cutting fluid is extremely important. It can effectively carry away cutting heat, lowering the temperature in the cutting zone; it provides lubrication, reducing friction between the tool and the workpiece; and it helps to flush away chips. High-performance cutting fluids and effective strategies like high-pressure cooling and MQL (Minimum Quantity Lubrication) can significantly improve machining conditions and tool life.

What are the requirements for machine tools when machining high-temperature alloys?

Due to high cutting forces and the tendency for vibration, machining high-temperature alloys requires machine tool equipment with high rigidity, good damping performance, and sufficient power to ensure process stability and accuracy.

Is the machining difficulty the same for different types of high-temperature alloys

No, it varies. Nickel-based high-temperature alloys are generally the most difficult to machine, with a high tendency for work hardening and extremely high strength and hardness at elevated temperatures. Cobalt-based alloys, containing many hard points, have excellent wear resistance but cause severe abrasive wear on tools, also making them very difficult to machine. Iron-based alloys are relatively easier to machine compared to nickel- and cobalt-based alloys, but still much more challenging than standard steels.

Can high-efficiency and precision machining be achieved for high-temperature alloys?

Yes, but it is challenging. By optimizing cutting parameters, selecting appropriate tools and cooling strategies, using high-rigidity equipment, and adopting advanced machining techniques (such as high-speed machining, hybrid machining), the efficiency and precision of high-temperature alloy machining can be effectively improved, but it requires precise process control.

Besides traditional cutting, what other methods can be used to machine high-temperature alloys?

For certain complex shapes or applications requiring extremely high surface quality, non-traditional machining methods can be used, such as Electrical Discharge Machining (EDM), Electrochemical Machining (ECM), or laser machining.