Molecular pump impellers are critical components in high-vacuum systems, requiring exceptional surface quality to ensure optimal performance. Achieving a surface roughness of Ra 0.06 demands precise control over grinding parameters, as surface finish directly impacts flow efficiency, cavitation resistance, and durability. This guide provides a systematic approach to adjusting grinding parameters, drawing on established engineering practices and technical data to deliver reliable results. Below, we outline the key factors, processes, and parameter settings necessary to meet this stringent surface finish requirement.

Understanding Surface Roughness and Ra 0.06 Requirements

Surface roughness, measured as Ra (arithmetic average roughness), quantifies the average deviation of surface irregularities from a mean line, expressed in micrometers (µm). An Ra value of 0.06 represents an ultra-smooth surface, typically required for molecular pump impellers to minimize turbulence, reduce friction losses, and enhance vacuum efficiency. Achieving this level of finish is challenging due to the complex geometry of impellers, which feature curved blades and narrow passages. The grinding process must balance material removal, surface integrity, and dimensional accuracy to meet these specifications.

Key considerations include:

- Material Properties: Impellers are often made from stainless steel, titanium, or aluminum alloys, each with distinct hardness and machinability characteristics.

- Geometry Constraints: Curved surfaces and tight tolerances limit tool access and increase the risk of surface defects.

- Process Stability: Variations in grinding conditions, such as wheel wear or coolant flow, can compromise surface quality.

By optimizing grinding parameters, manufacturers can achieve consistent Ra 0.06 finishes while maintaining impeller functionality.

Grinding Process Overview for Impeller Finishing

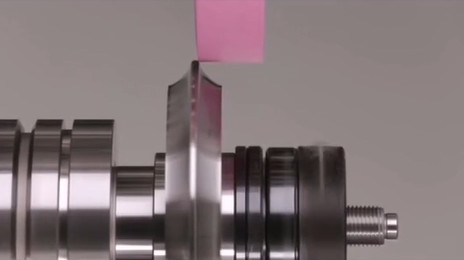

Grinding is a precision machining process that uses abrasive wheels to remove material and refine surface texture. For molecular pump impellers, the grinding process typically follows roughing and semi-finishing stages, with the final finishing stage targeting Ra 0.06. The process involves multiple variables, including wheel selection, machine setup, and operational parameters, all of which must be carefully controlled.

The grinding process for impellers generally includes:

- Rough Grinding: Removes bulk material to shape the impeller, using coarse abrasive wheels.

- Semi-Finishing: Refines the surface to an intermediate roughness (e.g., Ra 0.8–1.6 µm), preparing it for final finishing.

- Finish Grinding: Achieves the target Ra 0.06 through fine abrasives and precise parameter control.

Finish grinding is the most critical stage, as it determines the final surface quality. This stage often employs high-precision CNC grinding machines equipped with diamond or cubic boron nitride (CBN) wheels, which offer superior hardness and thermal stability for ultra-fine finishes.

Key Grinding Parameters for Ra 0.06 Surface Finish

Achieving Ra 0.06 requires meticulous adjustment of grinding parameters, including wheel characteristics, cutting conditions, and auxiliary systems. Below, we detail the primary parameters and their recommended settings, based on industry practices and technical studies.

Grinding Wheel Selection

The grinding wheel is the primary tool for surface finishing, and its properties significantly influence the outcome. For Ra 0.06, superabrasive wheels (diamond or CBN) are preferred due to their ability to maintain sharp cutting edges and produce fine surface textures.

| Parameter | Recommended Setting | Notes |

|---|---|---|

| Abrasive Type | Diamond or CBN | Diamond for non-ferrous materials (e.g., aluminum, titanium); CBN for ferrous materials (e.g., stainless steel). |

| Grit Size | 1000–2000 | Finer grits (e.g., 1500–2000) are critical for ultra-smooth finishes. |

| Bond Type | Vitrified or Resin | Vitrified bonds offer better wheel stability; resin bonds allow flexibility for complex geometries. |

| Wheel Hardness | Medium to Soft | Softer wheels reduce surface burn and improve finish quality. |

Wheel dressing is also critical to maintain abrasive sharpness and prevent clogging. Dressing should be performed using a diamond dresser at intervals of 10–20 grinding passes, depending on material and wheel wear.

Cutting Parameters

Cutting parameters, including wheel speed, workpiece speed, depth of cut, and feed rate, directly affect surface roughness. For Ra 0.06, low material removal rates and high wheel speeds are recommended to minimize thermal damage and surface irregularities.

| Parameter | Recommended Setting | Notes |

|---|---|---|

| Wheel Speed | 30–50 m/s | Higher speeds improve surface finish but require robust machine rigidity. |

| Workpiece Speed | 10–20 m/min | Lower speeds reduce vibration and improve precision. |

| Depth of Cut | 0.001–0.005 mm/pass | Shallow cuts minimize heat generation and surface defects. |

| Feed Rate | 0.01–0.05 mm/rev | Slower feeds enhance surface smoothness. |

Multiple passes with incrementally reduced depth of cut are often necessary to achieve Ra 0.06, with final passes focusing on polishing rather than material removal.

Coolant and Lubrication

Coolant plays a vital role in reducing heat, flushing debris, and preventing wheel loading. For molecular pump impellers, water-based synthetic coolants with low viscosity are recommended to ensure effective heat dissipation and minimal residue.

Recommended coolant settings:

- Type: Synthetic or semi-synthetic water-based coolant.

- Concentration: 5–10%.

- Flow Rate: 10–20 L/min, directed at the grinding zone.

- Pressure: 5–10 bar for optimal chip removal.

Proper coolant application reduces thermal distortion and surface burns, which are critical for achieving Ra 0.06 on sensitive materials like titanium or aluminum.

Machine and Tooling Setup

The grinding machine must offer high rigidity, precision, and vibration control to support ultra-fine finishing. CNC grinding machines with hydrostatic spindles and linear motors are ideal for molecular pump impellers.

Key setup considerations:

- Spindle Runout: Less than 0.002 mm to ensure consistent wheel contact.

- Workholding: Use vacuum chucks or magnetic fixtures to minimize clamping distortion.

- Tool Path: Program CNC tool paths to follow impeller contours, avoiding abrupt changes in direction.

- Vibration Damping: Install anti-vibration pads and balance wheels to reduce chatter marks.

Regular calibration of the machine and inspection of tooling ensure process repeatability and accuracy.

Practical Steps for Parameter Adjustment

To achieve Ra 0.06, follow these steps to systematically adjust grinding parameters:

- Select the Grinding Wheel: Choose a diamond or CBN wheel with a grit size of 1000–2000, based on the impeller material.

- Configure Machine Setup: Ensure spindle runout is minimal, and use precise workholding methods.

- Set Initial Parameters: Start with conservative settings (e.g., wheel speed 30 m/s, depth of cut 0.005 mm/pass).

- Perform Test Grinding: Conduct trial passes on a sample impeller and measure surface roughness using a profilometer.

- Adjust Parameters: Reduce depth of cut and feed rate incrementally if Ra exceeds 0.06, and increase wheel speed if feasible.

- Optimize Coolant Flow: Adjust coolant pressure and flow to eliminate thermal damage.

- Monitor Wheel Condition: Dress the wheel regularly to maintain sharpness and prevent glazing.

- Validate Results: Measure the final surface roughness and verify dimensional tolerances.

Iterative testing and measurement are essential to fine-tune parameters for specific impeller designs and materials.

Common Issues and Solutions

While adjusting grinding parameters, certain issues may arise that prevent achieving Ra 0.06. Below, we address common problems and their solutions:

- Surface Burns: Caused by excessive heat. Reduce depth of cut, increase coolant flow, or lower feed rate.

- Chatter Marks: Result from vibrations. Balance the wheel, check machine rigidity, or adjust workpiece speed.

- Inconsistent Roughness: Due to wheel wear or uneven surfaces. Dress the wheel frequently and ensure uniform tool paths are uniform.

- Material Smearing: Common with softer materials. Use a harder wheel bond or increase cutting speed.

Proactive monitoring and process control can mitigate these issues, ensuring a stable grinding operation.

Quality Assurance and Measurement

Verifying surface roughness is critical to confirm compliance with Ra 0.06. Use a high-precision surface profilometer with a stylus tip radius of 2 µm and a cutoff length of 0.08 mm for accurate measurements. Perform measurements at multiple locations on the impeller, including blade surfaces and hub areas, to ensure uniformity.

Additional quality checks include:

- Visual Inspection: Use a 10x magnifying loupe to detect micro-scratches or burns.

- >

- Dimensional Verification: Use coordinate measuring machines (CMMs) to confirm impeller geometry.

- Residual Stress Analysis: Employ X-ray diffraction to ensure no subsurface damage.

Document all measurements and parameters for traceability and process optimization.

Conclusion

Achieving a Ra 0.06 surface finish on molecular pump impellers requires precise control over grinding parameters, from wheel selection to machine setup. By following the recommendations outlined above—using superabrasive wheels, optimizing cutting conditions, and ensuring robust coolant application—manufacturers can consistently meet this stringent requirement. Systematic testing, parameter adjustment, and quality assurance are essential to address material and geometry-specific challenges. This approach ensures high-performance impellers that enhance the efficiency and reliability of molecular pump systems.