Compressor impellers are critical components in centrifugal compressors, requiring high dimensional accuracy to ensure optimal aerodynamic performance and operational efficiency. ZEISS coordinate measuring machines (CMMs) offer advanced metrology solutions to enhance inspection precision. This guide provides a systematic approach to leveraging ZEISS CMM technology for compressor impeller inspection, focusing on technical details, practical implementation, and best practices to achieve reliable and repeatable results.

Understanding Compressor Impeller Inspection Requirements

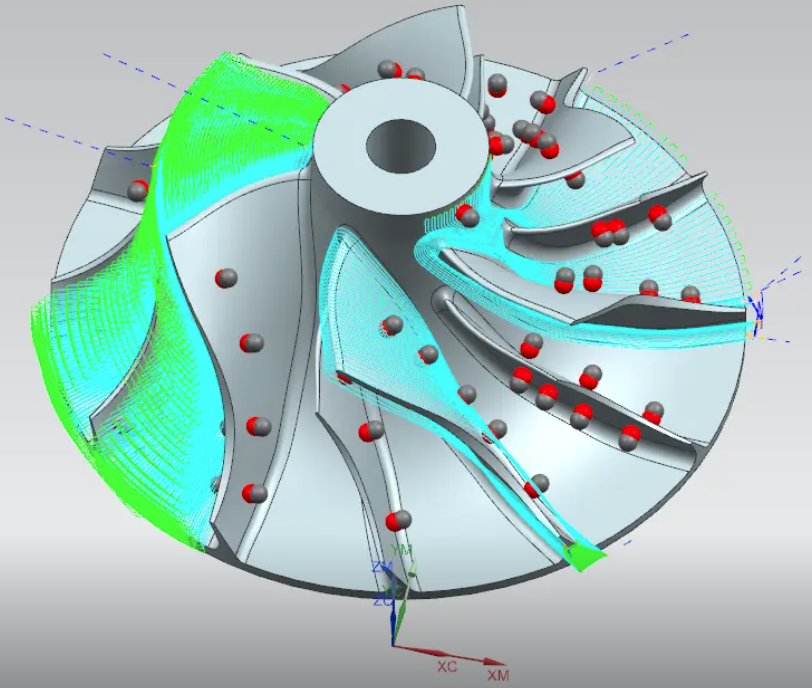

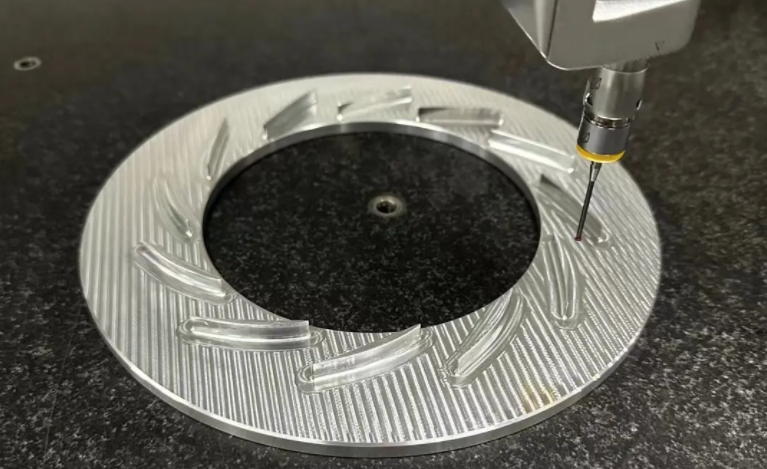

Compressor impellers feature complex geometries, including curved blades, tight tolerances, and critical features like leading edges, trailing edges, and hub profiles. Accurate inspection ensures that these components meet design specifications, which directly impact compressor efficiency, pressure ratio, and durability. Key parameters to measure include blade thickness (typically 0.5–2 mm), twist angle (ranging from 0° to 30°), chord length (50–150 mm), and surface profile deviations (within ±10–16 µm). Deviations beyond these tolerances can lead to flow separation, reduced efficiency, or mechanical failure.

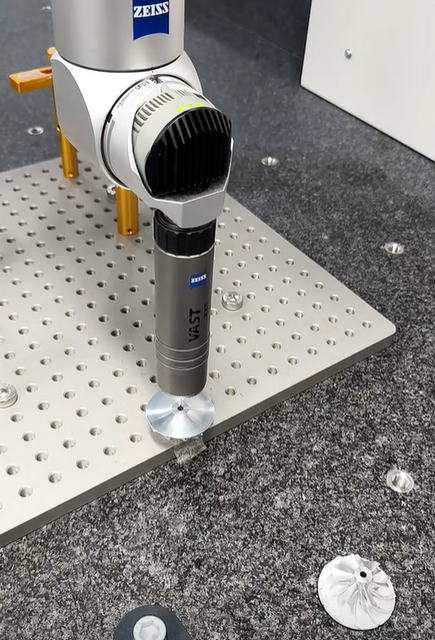

ZEISS CMM systems, such as the ZEISS O-INSPECT and ZEISS DuraMax, integrate contact and non-contact sensors to measure these parameters with high precision. Their ability to handle complex geometries and provide repeatable results makes them ideal for impeller inspection.

Optimizing Fixture Design for Stable Measurements

Stable part positioning is critical for accurate measurements. ZEISS CMM fixtures, made from materials like aluminum and hardened steel, ensure minimal vibration and thermal expansion during inspection. Proper fixture design reduces positioning errors and enhances repeatability.

Key considerations for fixture design include:

- Alignment with CMM Platform: Fixtures must align precisely with the CMM’s coordinate system to avoid measurement offsets. Misalignment can introduce errors up to 5 µm.

- Secure Clamping: Precision clamps prevent part movement without distorting the impeller’s shape. For example, ZEISS modular clamps allow secure holding of cylindrical or curved components.

- Minimal Vibration: Fixtures should minimize vibration, as even minor oscillations can cause measurement deviations of 1–2 µm.

- Consistent Setup: Standardized setup procedures reduce variability across inspections, ensuring repeatability within 0.5 µm.

ZEISS offers standard fixtures like universal vises and three-jaw chucks, as well as custom solutions for complex impeller geometries. For high-volume production, automated fixturing systems or palletized solutions can reduce setup time by up to 30%, improving throughput without compromising accuracy.

Selecting the Right ZEISS CMM Sensors

ZEISS CMMs support multiple sensors, each suited for specific impeller features. Choosing the appropriate sensor enhances measurement accuracy and efficiency.

| Sensor Type | Application | Accuracy | Key Features |

|---|---|---|---|

| VAST XXT (Contact) | Deep holes, side surfaces, oblique holes | ±1.5 µm | High-accuracy scanning, ideal for complex geometries |

| Discovery.V12 (Optical) | Surface profiles, blade edges | ±2 µm | 10-stage zoom lens, telecentric for accurate dimensions |

| DotScan (White Light) | Transparent parts, polished surfaces | ±1 µm | Non-contact, measures microstructures |

Contact Sensors (VAST XXT): These are ideal for measuring deep holes and side surfaces, capturing profiles with high accuracy. For example, VAST XXT can measure blade thickness with a repeatability of ±1.5 µm, suitable for tolerances of 10–16 µm.

Optical Sensors (Discovery.V12): These excel in measuring surface profiles and blade edges, offering a 10-stage zoom lens for high reproducibility. They are effective for chord length measurements, achieving accuracy within ±2 µm.

White Light Sensors (DotScan): These are used for non-contact measurement of polished or transparent surfaces, such as coated impellers, with an accuracy of ±1 µm. This is critical for detecting surface defects like scratches or coating thickness variations (e.g., 0.01–0.05 mm).

Combining these sensors allows comprehensive inspection of all impeller features, ensuring no critical dimension is overlooked.

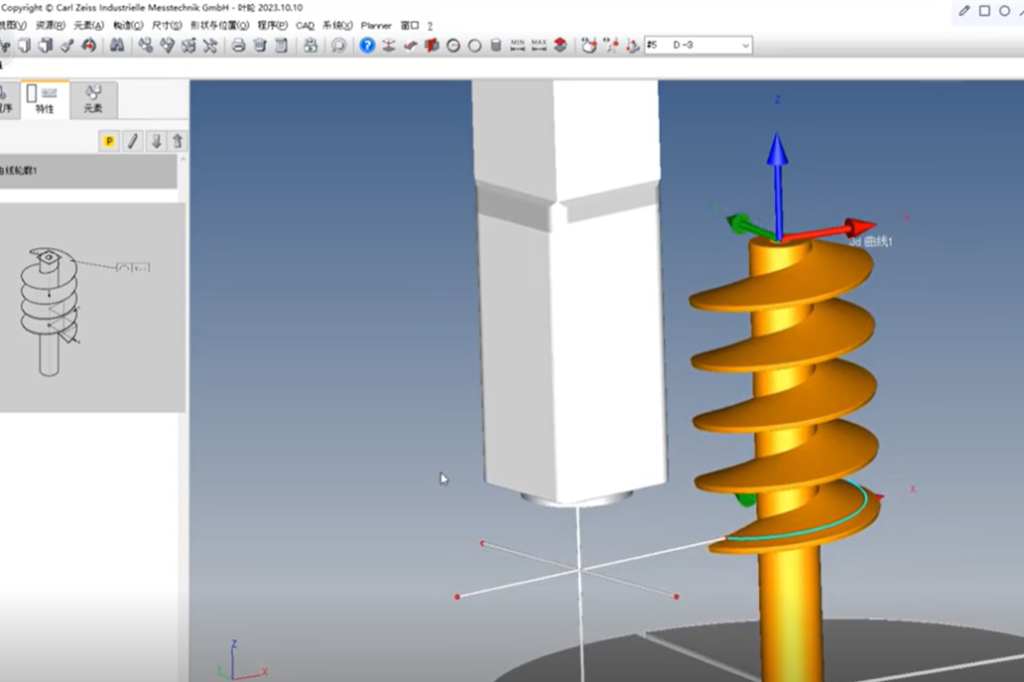

Leveraging ZEISS INSPECT Software for Data Analysis

ZEISS INSPECT software enhances inspection accuracy by providing robust tools for data analysis and automation. Its parametric approach ensures traceability and repeatability, critical for consistent impeller measurements.

Key Features of ZEISS INSPECT:

- Parametric Computation: Saves each inspection step, allowing operators to trace how results are calculated. This reduces errors by ensuring consistent measurement plans.

- Automated Defect Detection: Uses AI-based tools (e.g., ZADD Segmentation) to identify defects like surface cracks or profile deviations as small as 1 µm.

- CAD Integration: Matches measured data to CAD models, visualizing deviations with a color scale. For example, it can highlight twist angle deviations of ±0.5°.

- Reporting Tools: Generates customizable reports in graphical or tabular formats, facilitating compliance with standards like API 617.

For impeller inspection, ZEISS INSPECT can analyze complex geometries, such as blade camber and thickness, with a dimensional accuracy of ±2 µm. The Airfoil Inspection app is specifically designed for turbine and airfoil measurements, enabling precise evaluation of parameters like twist angle and chord length.

Implementing a Robust Inspection Process

A systematic inspection process ensures consistent and accurate results. The following steps outline a practical approach using ZEISS CMM systems:

- Pre-Inspection Preparation: Verify material certificates against ASTM standards to ensure compliance. Conduct visual inspections for surface finish and defects, such as scratches or burrs, which can affect measurements.

- Fixture Setup: Use ZEISS fixtures to secure the impeller, ensuring alignment within 0.1 mm. For cylindrical impellers, three-jaw chucks provide stable clamping.

- Sensor Selection and Calibration: Select appropriate sensors based on impeller features. Calibrate sensors to achieve accuracy within ±1 µm, as specified by ZEISS standards.

- Measurement Execution: Perform contact measurements for deep holes and side surfaces using VAST XXT, and optical measurements for surface profiles using Discovery.V12. Measure key parameters like blade thickness (0.5–2 mm) and twist angle (0°–30°).

- Data Analysis with ZEISS INSPECT: Import measurement data into ZEISS INSPECT, compare against CAD models, and identify deviations. For example, ensure profile deviations are within ±10 µm.

- Post-Inspection Validation: Conduct dye penetration or magnetic particle tests to detect cracks post-overspeed testing. Verify dimensional changes are within manufacturer specifications (e.g., ±5 µm for bore diameter).

- Reporting and Documentation: Generate detailed reports using ZEISS INSPECT, including graphical representations of deviations and compliance with API 617 standards.

This process ensures comprehensive inspection, covering all critical dimensions and surface characteristics of the impeller.

Ensuring Compliance with Industry Standards

Compressor impeller inspection must comply with standards like API 617, which specifies requirements for aerodynamic performance and mechanical integrity. ZEISS CMM systems facilitate compliance by providing accurate measurements and detailed reporting.

Key Compliance Checks:

- Material Verification: Confirm material properties, such as tensile strength (e.g., 800–1000 MPa for titanium alloys), using material test reports.

- Dimensional Accuracy: Measure critical dimensions, such as blade thickness and chord length, to ensure they meet tolerances (e.g., ±10 µm).

- Aerodynamic Testing: Conduct performance tests at five data points, including surge and choke conditions, as required by ASME PTC-1997. ZEISS INSPECT can analyze test data to verify isentropic efficiency (e.g., 85–90%).

- Non-Destructive Testing: Perform dye penetration tests post-overspeed to detect cracks, ensuring no defects exceed 0.01 mm in length.

ZEISS CMMs provide the precision needed to meet these standards, with measurement uncertainties as low as ±1.5 µm for contact sensors and ±1 µm for non-contact sensors.

Practical Considerations for High-Volume Production

In high-volume production, efficiency is as critical as accuracy. ZEISS CMM systems address this through automation and streamlined workflows.

Automation Features:

- Automated Fixturing: Palletized solutions allow rapid loading of multiple impellers, reducing setup time by 20–30%.

- Robotic Integration: ZEISS INSPECT’s Virtual Measuring Room enables simulation of automated measurements, minimizing operator intervention.

- Batch Inspection: Multi-part setups allow simultaneous measurement of multiple impellers, increasing throughput by up to 40%.

For example, a ZEISS O-INSPECT with a rotary table can measure cylindrical impellers horizontally or vertically, achieving a scanning speed of 8–12 mm/s with a form error of only 1.7–2.4 µm.

Case Study: Measuring a Centrifugal Compressor Impeller

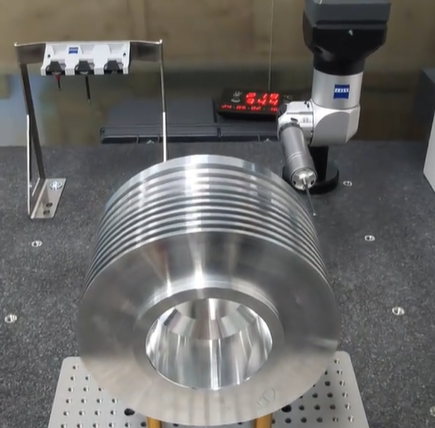

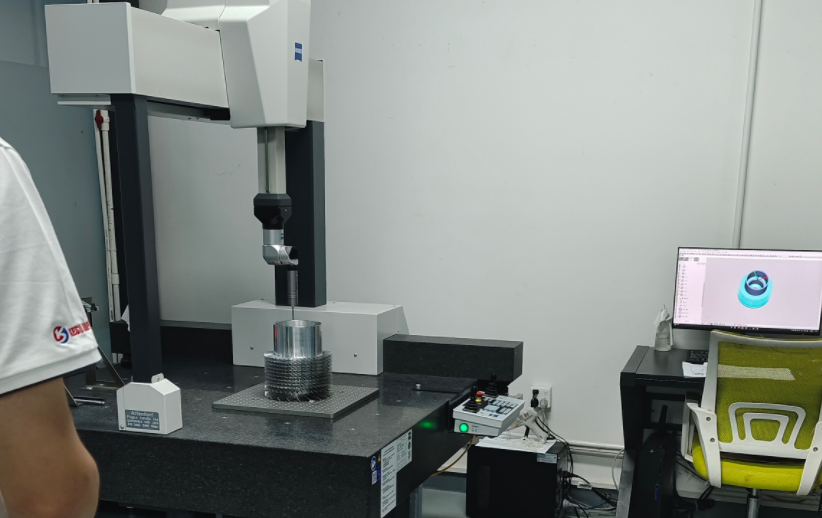

A practical example demonstrates the effectiveness of ZEISS CMM systems. Consider a centrifugal compressor impeller with 11 main blades and two splitter blades, designed to NASA-CC3 specifications. Key parameters include a blade thickness of 1.5 mm, a twist angle of 15°, and a chord length of 100 mm.

Inspection Process:

- Setup: The impeller was secured using a ZEISS three-jaw chuck, aligned within 0.05 mm.

- Measurement: VAST XXT measured blade thickness and hub profiles, achieving an accuracy of ±1.5 µm. Discovery.V12 measured surface profiles, detecting deviations of ±2 µm.

- Analysis: ZEISS INSPECT compared data to the CAD model, identifying a 5 µm deviation in the leading edge thickness, within the ±10 µm tolerance.

- Reporting: A graphical report highlighted deviations using a color scale, confirming compliance with API 617.

This process achieved a repeatability of ±0.5 µm and reduced inspection time by 25% compared to manual methods, demonstrating the efficiency and accuracy of ZEISS CMM systems.

Conclusion

Using ZEISS CMM systems, such as the O-INSPECT and DuraMax, significantly enhances compressor impeller inspection accuracy. By optimizing fixture design, selecting appropriate sensors, leveraging ZEISS INSPECT software, and implementing a robust inspection process, manufacturers can achieve dimensional accuracies within ±1–2 µm and ensure compliance with industry standards. These systems offer a reliable, efficient, and systematic approach to quality control, making them indispensable for high-precision impeller manufacturing.