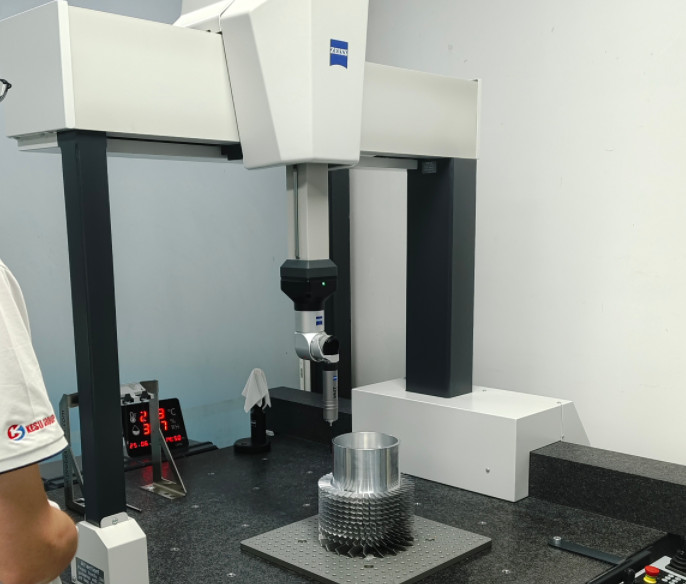

Compressor impellers are critical components in aerospace, automotive, and energy industries, requiring precise measurements to ensure performance, durability, and compliance with stringent standards. ZEISS 3D metrology solutions, including coordinate measuring machines (CMMs), optical systems, and advanced software, provide systematic and reliable methods to measure these complex geometries. This article details how ZEISS technology improves measurement efficiency for compressor impellers, focusing on technical capabilities, specific parameters, and practical applications.

Comprehensive Measurement of Complex Impeller Geometries

Compressor impellers feature intricate designs with multiple blades, curved surfaces, and tight tolerances. ZEISS 3D metrology systems are engineered to capture these geometries with high accuracy. The combination of tactile and optical measurement technologies allows for detailed analysis of blade profiles, surface contours, and root forms. For instance, ZEISS PRISMO CMMs achieve a length measurement error of 0.9 + L/350 µm, ensuring precise data collection for impellers up to 800 mm in diameter.

The ZEISS ScanBox, an automated optical 3D measuring machine, uses non-contact scanning to digitize impeller surfaces rapidly. It employs ATOS sensors with a resolution of up to 0.02 mm, enabling the detection of minute deviations in blade curvature or surface roughness. This capability is critical for verifying that impeller blades meet aerodynamic requirements, as even a 0.01 mm variation can impact airflow and efficiency. The system’s ability to scan entire components in a single pass reduces measurement time compared to traditional point-based methods.

ZEISS INSPECT Airfoil software complements these hardware solutions by providing specialized analysis tools for impeller blade geometries. It evaluates parameters such as leading-edge radius (typically 0.05–0.2 mm), chord length, and blade thickness with repeatability within ±0.005 mm. The software automates data processing, generating detailed reports that align with industry standards like AS9102, ensuring traceability and compliance.

High-Speed Data Acquisition for Production Environments

Production environments demand fast measurement cycles to maintain throughput. ZEISS 3D metrology systems are optimized for speed without compromising accuracy. The ZEISS PRISMO fortis, designed for shopfloor use, operates reliably at temperatures up to 40°C and achieves scanning speeds of up to 200 mm/s. Its VAST probing technology reduces probe qualification time to under 15 seconds, compared to 60 seconds for conventional systems, enabling rapid setup for impeller measurements.

The ZEISS CMM Acceleration Mode for Aerospace Applications further enhances efficiency. For example, the ZEISS VAST Rotary Table Axis (ZVRA) option defines rotary table axes in 15 seconds, allowing continuous measurement of impeller blades at multiple angles. This reduces total measurement time by up to 25%, critical for high-volume production where impellers are manufactured in quantities exceeding 10,000 annually.

Optical systems like the ZEISS COMET LED 2 offer additional speed advantages. With a capture rate of up to 1.2 million points per second, it completes a full impeller scan in under 5 minutes, compared to 20–30 minutes for manual CMM probing. The system’s photogrammetry integration ensures accuracy by acquiring 3D reference points with a precision of ±0.015 mm, making it suitable for large impellers used in gas turbines or turbochargers.

Integration of Tactile and Optical Technologies

ZEISS 3D metrology combines tactile and optical methods to address diverse impeller measurement needs. Tactile CMMs, such as the ZEISS O-INSPECT, use probes with a resolution of 0.001 mm to measure internal features like root forms or mounting slots, which are inaccessible to optical systems. The machine’s ISO-10360 compliance ensures measurement accuracy for critical dimensions, such as slot widths of 2–5 mm with tolerances of ±0.01 mm.

Optical systems, like the ZEISS ATOS Q, excel at capturing external surfaces. With a measurement volume of up to 500 x 370 mm, it is ideal for medium-sized impellers. The system’s blue light technology minimizes reflections on polished impeller surfaces, achieving a surface point density of 12 points/mm². This enables detailed inspection of blade surface roughness, with Ra values as low as 0.8 µm, ensuring compliance with performance specifications.

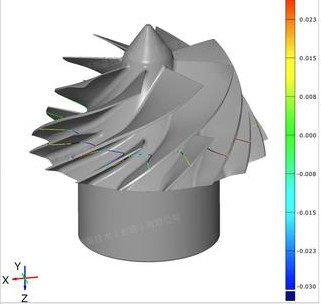

The ZEISS Quality Suite integrates data from both tactile and optical systems into a unified platform. This allows seamless comparison of impeller measurements against CAD models, with deviation maps highlighting areas exceeding tolerances (e.g., ±0.02 mm). The suite’s automation features reduce operator intervention, cutting data analysis time by up to 30% compared to standalone software solutions.

Ensuring Compliance with Industry Standards

Compressor impellers must meet rigorous standards, such as AS13003 for aerospace applications. ZEISS 3D metrology systems are designed to ensure compliance through traceable measurements. The ZEISS METROTOM 6 scout, a computed tomography (CT) system, provides non-destructive inspection of internal impeller structures. It achieves a voxel resolution of 10 µm, allowing detection of defects like voids or inclusions with diameters as small as 0.05 mm.

The ZEISS PRISMO ultra, with a length measurement error of 0.5 + L/500 µm, is used for calibration tasks, ensuring that impeller measurements are traceable to international metrology standards. Its high rigidity and air-bearing technology minimize environmental influences, maintaining accuracy in production settings with vibration levels up to 0.1 mm/s².

ZEISS software solutions, such as ZEISS CALYPSO, automate compliance reporting. The software generates First Article Inspection (FAI) reports in under 10 minutes, detailing parameters like blade angle (typically 30–45°) and tip clearance (0.1–0.3 mm). These reports streamline audits and reduce documentation time by up to 50% compared to manual processes.

Practical Applications in Impeller Manufacturing

ZEISS 3D metrology is widely applied in impeller manufacturing, from initial forging to final machining. During forging, ZEISS technologies verify die conformity, ensuring that impeller blanks meet dimensional tolerances of ±0.1 mm. The ZEISS ScanBox identifies die wear patterns, extending die life by up to 20% through predictive maintenance.

In rough milling, ZEISS shopfloor CMMs measure blade profiles under harsh conditions, with dust levels up to 10 mg/m³. The systems’ robust design ensures reliable operation, capturing features like airfoil edges with radii of 0.2–0.5 mm. This enables real-time process adjustments, reducing scrap rates by up to 15%.

For final machining, the ZEISS PRISMO fortis measures critical features like tip clearances and root forms with tolerances of ±0.005 mm. Its high-speed scanning ensures that 100% inspection is feasible, even for production runs exceeding 500 impellers per week. This eliminates the need for sampling, improving quality assurance.

Quantitative Benefits of ZEISS 3D Metrology

The following table summarizes key performance metrics of ZEISS 3D metrology systems for compressor impeller measurement:

| System | Measurement Accuracy | Scanning Speed | Key Application |

|---|---|---|---|

| ZEISS PRISMO fortis | 0.9 + L/350 µm | Up to 200 mm/s | Final machining inspection |

| ZEISS ScanBox | ±0.02 mm | 1.2 million points/s | Full-surface digitization |

| ZEISS METROTOM 6 scout | 10 µm voxel resolution | Single scan in 10 min | Internal defect detection |

These metrics demonstrate ZEISS’s ability to deliver precise, high-speed measurements tailored to impeller production needs. The systems reduce measurement time by up to 40% compared to traditional methods, enabling manufacturers to meet tight production schedules.

Conclusion

ZEISS 3D metrology enhances compressor impeller measurement efficiency through precise, high-speed, and integrated solutions. Its CMMs, optical systems, and software address the complex geometries and tight tolerances of impellers, ensuring compliance with industry standards. By streamlining data acquisition, analysis, and reporting, ZEISS enables manufacturers to improve productivity and quality assurance. These technologies are proven in real-world applications, from forging to final machining, making ZEISS a trusted partner in impeller manufacturing.