Impellers are pivotal components in industries such as energy, aerospace, petrochemicals, water treatment, and automotive, converting fluid or gas kinetic energy into mechanical energy. Their complex geometries and critical performance requirements make precise design and manufacturing essential. This article explores how advanced 3D scanning, specifically using the ZEISS GOM Scan 1, revolutionizes impeller reverse engineering, addressing challenges in design accuracy, quality control, and production efficiency.

Understanding Impeller Reverse Engineering

Reverse engineering involves analyzing an existing impeller to create a digital model that replicates its geometry and functionality. This process is vital for redesigning legacy parts, improving performance, or manufacturing replacements when original design data is unavailable. By leveraging high-precision 3D scanning, engineers can capture detailed surface data, enabling accurate reconstruction of complex impeller geometries for design optimization, quality validation, and production.

In my view, reverse engineering is not just about replicating a part but about unlocking opportunities for innovation. The high-fidelity data from 3D scanning allows engineers to analyze performance limitations, refine designs, and integrate modern manufacturing techniques, ultimately enhancing impeller efficiency and reliability.

Challenges in Traditional Impeller Inspection and Reverse Engineering

Impeller blades feature intricate spatial curves, high twist angles, and elevation, posing significant challenges for traditional measurement methods like gauges, fixtures, or coordinate measuring machines (CMMs). These methods are often inadequate for capturing the full complexity of impeller surfaces, leading to inefficiencies and inaccuracies. Key challenges include:

- Complex Geometry: Spatial curved surfaces and variable angles make manual measurements difficult and imprecise.

- Time-Consuming Processes: Traditional methods require extensive setup and manual data collection, slowing down workflows.

- Human Error: Manual measurements are prone to inconsistencies, impacting the accuracy of reverse-engineered models.

- Limited Data Resolution: Conventional tools often fail to capture comprehensive surface data, limiting the quality of digital models.

These limitations highlight the need for advanced technologies like 3D scanning to streamline reverse engineering and ensure precision.

ZEISS GOM Scan 1: A Game-Changer for Impeller Reverse Engineering

The ZEISS GOM Scan 1, an optical 3D fringe projection scanner, addresses these challenges by providing high-resolution, non-contact surface measurements. By projecting blue light fringes and utilizing stereo camera principles, it captures detailed 3D data of impeller surfaces, including curves, holes, and edges, with exceptional accuracy. This data is used to construct precise digital models for reverse engineering, quality control, and design optimization.

Key Technical Specifications

The GOM Scan 1 is designed for flexibility and precision, making it ideal for complex components like impellers. Its key features include:

| Feature | Description |

|---|---|

| Scanning Technology | Blue light fringe projection with stereo camera system |

| Resolution | Up to 0.01 mm point spacing for high-detail capture |

| Measurement Volume | 100–400 mm, adaptable for small to medium parts |

| Environmental Adaptability | Compensates for ambient light changes during scanning |

| Software Integration | ZEISS Quality Suite for data processing and analysis |

These specifications enable the GOM Scan 1 to capture intricate impeller geometries efficiently, reducing measurement time from hours to minutes while maintaining high accuracy.

Workflow for Impeller Reverse Engineering

The reverse engineering process using the GOM Scan 1 involves several key steps:

- Data Acquisition: The scanner projects blue light fringes to capture the impeller’s surface geometry, generating a dense point cloud of 3D coordinates.

- Data Processing: ZEISS Quality Suite processes the point cloud into a triangular mesh, creating a high-fidelity digital model of the impeller.

- Surface Reconstruction: The mesh is converted into a parametric CAD model, replicating the original design intent for further modification or analysis.

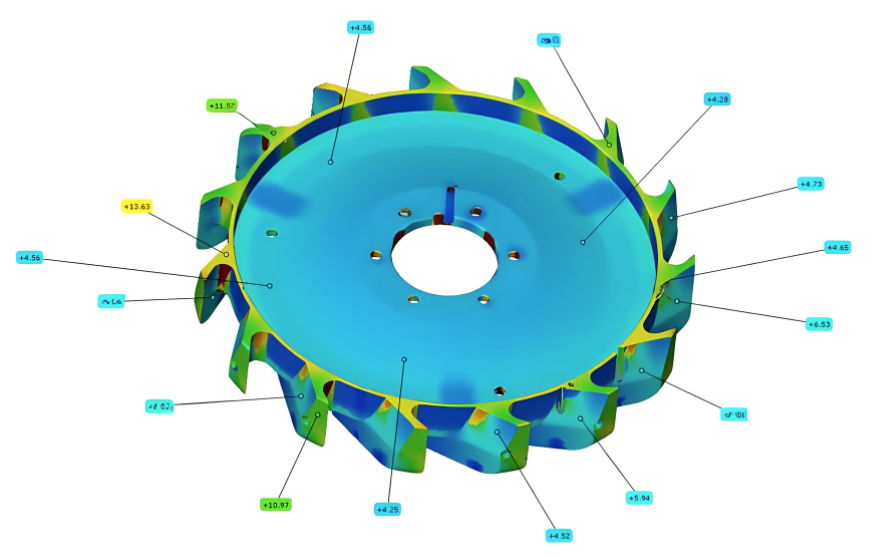

- Quality Analysis: The digital model is compared against design specifications or reference CAD data to identify deviations in surface shape, dimensions, or material thickness.

- Design Optimization: Engineers use the model to refine blade profiles, improve aerodynamic performance, or adapt the design for modern manufacturing methods.

This streamlined workflow ensures that the reverse-engineered impeller meets performance requirements while minimizing development time.

Benefits of 3D Scanning for Impeller Reverse Engineering

Using the ZEISS GOM Scan 1 for impeller reverse engineering offers significant advantages over traditional methods. These benefits align with the needs of modern manufacturing for speed, precision, and flexibility:

| Benefit | Impact |

|---|---|

| High Precision | Achieves sub-millimeter accuracy, ensuring accurate replication of complex geometries. |

| Rapid Data Capture | Reduces measurement time by up to 80% compared to traditional methods. |

| Comprehensive Data | Captures full surface geometry, enabling detailed analysis and reconstruction. |

| Non-Contact Measurement | Eliminates physical wear on delicate components and reduces human error. |

| Enhanced Quality Control | Generates detailed deviation reports, identifying surface and dimensional issues early. |

In my perspective, the ability to rapidly generate accurate digital models not only accelerates reverse engineering but also empowers engineers to iterate designs iteratively, fostering innovation in impeller performance and manufacturing efficiency.

Applications Beyond Reverse Engineering

The high-precision 3D data obtained from scanning supports multiple applications:

- Quality Control: Comparing scanned data with CAD models to detect manufacturing defects or deviations.

- Simulation and Analysis: Using digital models for computational fluid dynamics (CFD) to optimize aerodynamic performance.

- Maintenance and Repair: Creating replacement parts for legacy impellers without original drawings.

- Additive Manufacturing: Generating models for 3D printing to produce prototypes or production parts.

These applications demonstrate the versatility of 3D scanning, making it a cornerstone technology for modern impeller design and production.

Conclusion

Advanced 3D scanning technology, exemplified by the ZEISS GOM Scan 1, transforms impeller reverse engineering by providing accurate, comprehensive geometric data. This enables precise digital modeling, quality validation, and design optimization, addressing the limitations of traditional measurement methods. By integrating high-resolution scanning with powerful software like ZEISS Quality Suite, manufacturers can enhance impeller performance, reduce development cycles, and improve overall system efficiency. In my view, this technology not only solves current engineering challenges but also paves the way for future innovations in impeller design and manufacturing.