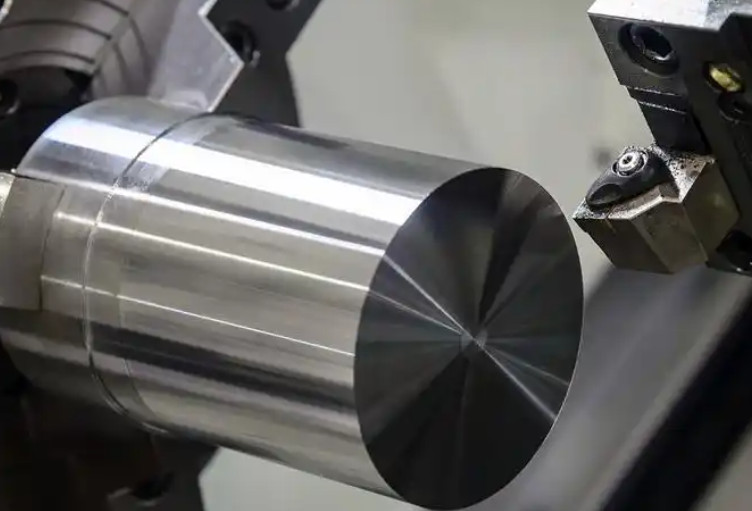

Custom465, a martensitic precipitation-hardening stainless steel developed by Carpenter Technology, is renowned for its exceptional mechanical properties and corrosion resistance. With a tensile strength of up to 1800 MPa, high hardness (47 HRC in H950 condition), and excellent fracture toughness, it is widely used in demanding applications. However, its high strength, toughness, and specific alloying elements make it a challenging material for high-speed machining. This article explores the critical factors influencing the efficient high-speed turning of Custom465, including material properties, cutting parameters, tool selection, and finite element simulation, providing practical guidance for optimizing the machining process.

Material Properties of Custom465

Custom465’s chemical composition and metallurgical characteristics significantly influence its machinability. The alloy contains high levels of chromium (Cr), nickel (Ni), molybdenum (Mo), and titanium (Ti), which contribute to its unique properties. These elements enhance corrosion resistance, strength, and toughness but also increase machining difficulty. The key properties affecting machining are:

- Corrosion Resistance: High chromium content provides corrosion resistance comparable to Custom630 or 13-8Mo, making it suitable for harsh environments.

- High Hardness: In the H950 condition, Custom465 achieves a hardness of 47 HRC, contributing to its excellent mechanical performance but increasing tool wear.

- High Strength: With a tensile strength of 1800 MPa and a cold-drawn section shrinkage rate exceeding 70%, the material resists deformation during cutting, leading to high cutting forces.

- Poor Wear Resistance: Despite its toughness and corrosion resistance, Custom465 has relatively low wear resistance, which affects chip formation and surface quality.

These properties result in several machining challenges, including severe tool wear due to friction and material affinity, significant work hardening, high cutting forces, and elevated cutting temperatures. Understanding these characteristics is essential for selecting appropriate tools and parameters.

Machining Challenges of Custom465

The unique properties of Custom465 lead to specific machining difficulties that must be addressed to achieve efficient high-speed turning. The following issues are commonly encountered:

- Tool Wear: The high hardness and presence of hard phases, combined with severe work hardening, accelerate tool wear. Friction between the tool and workpiece, along with material affinity, further exacerbates this issue.

- Work Hardening: Custom465’s high plasticity and toughness, coupled with a high strengthening coefficient, result in significant plastic deformation during cutting, leading to work hardening. This creates a hard, brittle surface layer that complicates subsequent cuts.

- High Cutting Forces: The alloy’s high strength and atomic bonding result in large and fluctuating cutting forces, increasing tool stress and vibration.

- Elevated Cutting Temperatures: The high deformation energy and friction during cutting generate substantial heat, concentrating in the cutting zone and affecting tool life and workpiece quality.

These challenges necessitate careful selection of cutting tools, parameters, and cooling strategies to maintain machining efficiency and workpiece quality.

Key Factors Affecting Cutting Performance

Several factors influence the high-speed turning of Custom465, with cutting temperature being a critical parameter due to its impact on tool life, surface quality, and dimensional accuracy. The primary factors are:

Cutting Heat and Temperature

Cutting heat arises from elastic and plastic deformation of the workpiece and friction between the tool, chip, and workpiece. This heat elevates the cutting zone temperature, accelerating tool wear and affecting surface quality. Controlling cutting temperature is vital for stable and efficient machining.

Influential Parameters

The following parameters significantly affect cutting temperature and overall machining performance:

- Workpiece Material: Higher strength and hardness increase cutting heat, while higher thermal conductivity aids heat dissipation.

- Tool Geometry: Parameters such as rake angle, clearance angle, and nose radius influence heat generation and chip flow. Larger rake angles reduce cutting temperature but may decrease tool strength if excessive.

- Cutting Parameters: Cutting speed has the most significant impact on temperature, followed by feed rate and depth of cut. Higher speeds increase heat generation, necessitating robust tools.

- Tool Wear and Coolant: Worn tools increase friction and temperature, while effective coolant use can significantly reduce cutting temperatures.

Finite Element Simulation of the Machining Process

Finite element analysis (FEA) is a powerful tool for understanding the machining process and optimizing parameters. Using software like Deform 3D, simulations can model cutting temperature, tool wear, and chip formation, reducing the need for extensive physical trials. The simulation process involves five key steps: geometric modeling, meshing, setting initial conditions, running the simulation, and post-processing. The following subsections detail the impact of key parameters on cutting temperature, based on simulated results.

Effect of Rake Angle

Simulations using Deform 3D with varying rake angles show that increasing the rake angle reduces cutting temperature due to lower cutting forces and improved chip flow. However, excessively large rake angles reduce the heat dissipation area, potentially offsetting the benefits. Optimal rake angles balance temperature reduction with tool strength.

Effect of Cutting Speed

Simulations indicate that cutting speed has a significant linear effect on cutting temperature. As speed increases, the cutting zone temperature rises rapidly, necessitating high-hardness tools with heat-resistant coatings (e.g., PVD or TN6010) to maintain tool life and machining stability.

Effect of Feed Rate

Increasing the feed rate raises cutting temperature, but the rate of increase diminishes at higher feed rates. This suggests that moderate feed rates can balance productivity and thermal management.

Effect of Depth of Cut

A larger depth of cut increases cutting temperature due to greater material removal and cutting forces. Careful control of depth is essential to manage heat and ensure tool longevity.

Experimental Validation of Machining Parameters

Physical experiments were conducted using Custom465 in the H950 condition to validate simulation results and optimize machining parameters. The experiments focused on rough and finish turning of external surfaces and boring of internal holes, with specific tool selections and cutting parameters tested.

Rough Turning of External Surfaces

Rough turning trials used C-shaped inserts with varying nose radii and cutting parameters. The results are summarized in the table below:

| Tool Number | Cutting Speed (m/min) | Feed Rate (mm/r) | Depth of Cut (mm) | Performance |

|---|---|---|---|---|

| Tool 1 | 80-100 | 0.2-0.3 | 1.0-1.5 | Good performance, longer tool life with larger nose radius |

| Tool 2 | 80-100 | 0.2-0.3 | 1.0-1.5 | Good performance, stable machining |

| Tool 3 | 80-100 | 0.2-0.3 | 1.0-1.5 | Poor performance, rapid wear |

| Tool 4 | 80-100 | 0.2-0.3 | 1.0-1.5 | Poor performance, unsuitable for roughing |

Tools 1 and 2 exhibited superior performance, with larger nose radii improving tool life. Higher cutting speeds led to rapid tool wear and unstable machining, indicating the need for controlled parameters.

Finish Turning of External Surfaces

Finish turning trials used V-shaped inserts with nose radii of R0.2 mm or R0.4 mm. Optimal results were achieved with Tools 3 and 4 at cutting speeds below 120 m/min and depths of cut below 0.15 mm, ensuring stable surface roughness and minimal tool wear.

Rough and Finish Boring of Internal Holes

Rough boring used smaller inserts due to hole size constraints, with Tool 2 showing excellent performance across cutting speed, feed rate, and depth of cut. For finish boring, maintaining a feed rate of 0.08 mm/r, cutting speed of 30-60 m/min, and depth of cut of 0.05-0.10 mm ensured high surface quality and tool stability.

Practical Recommendations for Machining Custom465

Based on simulation and experimental results, the following recommendations optimize high-speed turning of Custom465:

- Rough Machining: Use C-shaped inserts with large nose radii to ensure tool strength and wear resistance. Cutting parameters should prioritize stability over aggressive material removal.

- Finish Machining: Employ V-shaped inserts with R0.2 mm or R0.4 mm nose radii for superior surface quality. Control cutting speed (<120 m/min) and depth of cut (<0.15 mm) to minimize tool wear.

- Chip Breaker Design: Select chip breakers with rapid contour changes (e.g., WIDIA SM) to facilitate chip breaking, preventing entanglement and surface damage.

- Tool Coatings: Use high-temperature-resistant coatings like PVD or TN6010 to withstand elevated cutting temperatures and extend tool life.

- Cutting Parameters: Balance cutting speed, feed rate, and depth of cut to maintain stable machining conditions while maximizing efficiency.

- Process Planning: Perform extensive material removal before final heat treatment when the material is softer, reducing the cutting load during finish machining.

Conclusion

High-speed turning of Custom465 stainless steel requires careful consideration of material properties, cutting parameters, and tool selection. Its high strength, hardness, and toughness pose significant machining challenges, including tool wear, work hardening, high cutting forces, and elevated temperatures. Finite element simulations and experimental validation reveal that optimizing tool geometry, selecting heat-resistant coatings, and controlling cutting parameters are critical for efficient machining. By implementing C-shaped inserts for roughing, V-shaped inserts for finishing, and appropriate chip breaker designs, manufacturers can achieve stable machining, high surface quality, and extended tool life. These findings provide a systematic approach to machining Custom465, ensuring efficiency and precision in high-performance applications.