Laser processing is a pivotal technology in modern industry, enabling high-precision material manipulation for cutting, welding, marking, and more. By focusing intense light beams, lasers achieve micron-level accuracy, high repeatability, and efficiency across diverse materials like metals, polymers, and ceramics. This article provides a comprehensive overview of laser processing techniques, their precision parameters, and their applications in manufacturing, electronics, medical, and aerospace sectors. Technical details and practical insights ensure a thorough understanding of this technology’s capabilities and limitations.

Laser Processing Techniques

Laser processing encompasses multiple methods, each designed for specific material interactions and industrial needs. These techniques leverage laser beam properties like wavelength, power, and pulse duration to achieve desired outcomes. Below, we explore the primary techniques and their technical specifications.

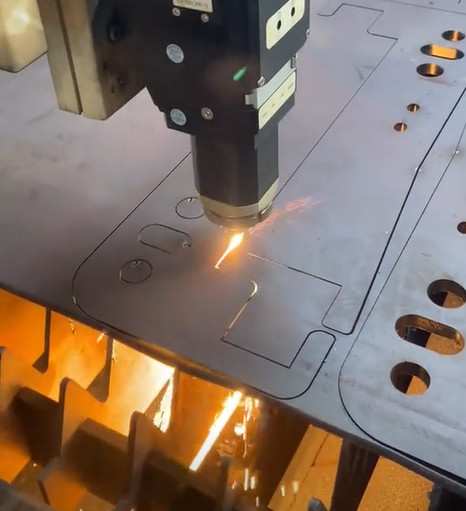

Laser Cutting

Laser cutting uses a focused laser beam to melt, vaporize, or ablate material, creating precise cuts with minimal thermal impact. Fiber lasers (wavelength 1.06–1.07 μm, power 500 W–20 kW) are widely used for metals like stainless steel and aluminum. For example, a 4 kW fiber laser cuts 1 mm steel at 20 m/min with a kerf width of 0.1 mm. Ultrafast lasers (pulse duration 200 fs–10 ps) minimize heat-affected zones (HAZ), achieving edge roughness below 1 μm. Assist gases like nitrogen (5–20 bar) or oxygen enhance cut quality. Key parameters include laser power, cutting speed (0.5–50 m/min), focal length (50–200 mm), and gas pressure, which determine precision and throughput.

Laser Welding

Laser welding fuses materials by melting them with a focused beam, offering deep penetration and high-strength joints. Continuous-wave fiber lasers (1–10 kW) or pulsed Nd:YAG lasers (pulse energy 1–100 J) are common, achieving weld depths of 0.5–6 mm and widths of 0.1–1 mm. In electric vehicle battery production, laser welding joins copper and aluminum foils at 500 mm/s with 0.01 mm accuracy. Shielding gases like argon (10–30 L/min) prevent oxidation. Parameters such as beam diameter (0.1–0.6 mm), pulse frequency (1–100 Hz), and welding speed influence weld quality, minimizing defects like porosity or cracking.

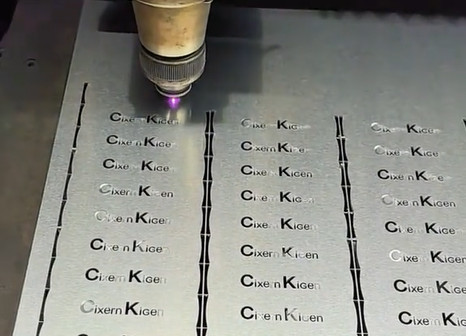

Laser Marking and Engraving

Laser marking and engraving modify material surfaces to create permanent identifiers like serial numbers or barcodes. Fiber lasers (20–100 W, 1.06 μm) and CO₂ lasers (10–100 W, 10.6 μm) are used, with marking depths from 0.01 mm (surface marking) to 1 mm (deep engraving). For example, marking titanium medical implants achieves 10 μm positional accuracy, withstanding sterilization. Scanning speeds reach 7,000 mm/s, and pulse frequencies (20–100 kHz) control contrast. Parameters like laser power, beam focus, and repetition rate ensure high-resolution marks without material damage.

Laser Ablation

Laser ablation removes material through vaporization, ideal for micromachining and surface texturing. Ultrafast lasers (pulse duration 200 fs–10 ps, pulse energy 1–100 μJ) minimize thermal effects, achieving feature sizes as small as 0.1 μm. In electronics, femtosecond lasers drill 10 μm vias in silicon wafers at 1 mm³/s. Parameters like repetition rate (50–1000 kHz), beam spot size (1–10 μm), and energy density (0.1–10 J/cm²) determine precision and material removal rate, ensuring no micro-cracks in brittle materials like ceramics.

Laser Drilling

Laser drilling creates precise holes using pulsed lasers (e.g., Nd:YAG or fiber, 10 ns–1 ms pulse duration). Hole diameters range from 10 μm to 1 mm, with aspect ratios up to 20:1. In aerospace, drilling 50 μm cooling holes in turbine blades achieves ±5 μm tolerance at 100 holes/s. Assist gases like oxygen (5–15 bar) reduce recast layers. Parameters such as pulse energy (0.1–10 J), repetition rate (10–1000 Hz), and focal position control hole taper (0.5–2°) and quality.

Precision in Laser Processing

Precision defines laser processing’s value, enabling industries to meet tight tolerances and quality standards. Precision is quantified by accuracy (deviation from target) and repeatability (consistency across operations). Below, we detail factors affecting precision and provide quantitative metrics.

Factors Affecting Precision

Several elements influence laser processing precision:

- Beam Quality: The M² factor (1.1–1.3 for fiber lasers) determines focusability. A near-Gaussian beam (M² ≈ 1) achieves spot sizes down to 10 μm.

- Motion Systems: High-precision stages (e.g., air-bearing systems) provide ±1 μm positional accuracy, critical for micromachining.

- Pulse Characteristics: Ultrafast lasers (pulse duration <10 ps) reduce HAZ, enabling sub-100 nm features in glass or semiconductors.

- Material Properties: Reflectivity and thermal conductivity affect outcomes. Copper’s high reflectivity at 1.06 μm requires green lasers (532 nm) for better absorption.

- Environmental Control: Stable temperature and vibration-free setups maintain beam alignment, with industrial systems using active cooling and dampening mounts.

Precision Metrics

| Technique | Feature Size (μm) | Positional Accuracy (μm) | Repeatability (μm) | Common Materials |

|---|---|---|---|---|

| Laser Cutting | 100–500 | ±10 | ±5 | Metals, Plastics, Ceramics |

| Laser Welding | 100–1000 | ±20 | ±10 | Metals, Polymers |

| Laser Marking | 10–1000 | ±10 | ±5 | Metals, Glass, Plastics |

| Laser Ablation | 0.1–100 | ±1 | ±0.5 | Semiconductors, Ceramics |

| Laser Drilling | 10–500 | ±5 | ±2 | Metals, Ceramics, Polymers |

Applications of Laser Processing

Laser processing’s versatility makes it essential in industries requiring precision and efficiency. Its non-contact nature and material adaptability drive its widespread adoption. Below are key applications with technical details.

Manufacturing and Automotive

In manufacturing, laser cutting shapes sheet metals (0.5–25 mm thick) with 0.1 mm kerf widths, used in automotive body panels. A 6 kW fiber laser welds steel at 5 m/min, achieving 10:1 depth-to-width ratios. Laser drilling creates 50 μm fuel injector nozzles at 100 Hz, ensuring consistent flow rates. In EV battery assembly, laser welding joins 0.2 mm copper foils with 0.01 mm accuracy, ensuring leak-proof seals.

Electronics and Semiconductors

Laser processing is critical for microelectronics. Femtosecond lasers ablate silicon wafers with 0.1 μm resolution, creating 10 μm vias for 5G chips. Laser scribing in solar cell production achieves 10 μm-wide lines, boosting efficiency by 1–2%. Laser marking applies 20 μm barcodes on circuit boards, readable after 100 thermal cycles, ensuring traceability.

Medical Devices

Laser processing enables precise medical device fabrication. Femtosecond lasers cut nitinol stents with 10 μm accuracy, avoiding thermal damage. CO₂ lasers mark glass syringes with 0.05 mm-deep codes, meeting FDA traceability standards. Laser welding joins titanium implants with 0.1 mm welds, ensuring biocompatibility and strength.

Aerospace

Aerospace relies on laser processing for high-precision components. Laser drilling creates 50–100 μm cooling holes in turbine blades with ±2 μm tolerance. Laser welding joins titanium alloys with 500 MPa strength. Laser texturing applies 10 μm patterns to reduce wear by 10%, enhancing component longevity.

Technical Considerations

Laser processing faces specific limitations that require careful management:

- Material Reflectivity: Reflective materials like copper demand specialized lasers (e.g., 532 nm) to improve energy absorption.

- Thermal Effects: Nanosecond lasers may induce micro-cracks in ceramics, requiring ultrafast lasers for brittle materials.

- Equipment Costs: High-precision systems like femtosecond lasers involve significant investment, though they reduce waste and maintenance costs over time.

Conclusion

Laser processing delivers unmatched precision and versatility across cutting, welding, marking, ablation, and drilling. With feature sizes down to 0.1 μm and accuracies within ±1 μm, it meets the demands of industries like manufacturing, electronics, medical, and aerospace. By understanding technical parameters and material interactions, manufacturers can optimize processes for efficiency and quality. Laser processing remains a cornerstone of precision engineering, driving advancements in product performance and reliability.

FAQ

What are the main types of laser processing techniques?

Laser processing includes several core techniques:

Laser Cutting: Uses focused laser beams to melt or vaporize materials, suitable for metals, plastics, and ceramics. For example, a 4 kW fiber laser can cut 1 mm steel at 20 m/min with a 0.1 mm kerf width.

Laser Welding: Fuses materials by melting, ideal for high-strength joints (e.g., EV battery copper-aluminum foils welded at 0.01 mm accuracy).

Laser Marking & Engraving: Creates permanent surface identifiers, such as serial numbers on titanium medical implants with 10 μm positional accuracy.

Laser Ablation: Removes material via vaporization for micromachining, achieving features as small as 0.1 μm in semiconductors.

Laser Drilling: Produces precise holes, e.g., 50 μm cooling holes in aerospace turbine blades.

How are laser wavelengths and power selected for different applications?

Fiber Lasers: 1.06–1.07 μm wavelength, 500 W–20 kW power, optimal for metal cutting/welding.

CO₂ Lasers: 10.6 μm wavelength, 10–100 W power, used for marking non-metallic materials (e.g., plastics).

Ultrafast Lasers (femtosecond/picosecond): <10 ps pulse duration, minimize thermal damage for high-precision microfabrication.

What factors influence laser processing precision?

Beam Quality: M² factor (e.g., 1.1–1.3 for fiber lasers) determines focusability; near-Gaussian beams achieve 10 μm spot sizes.

Motion Systems: High-precision stages (e.g., air bearings) enable ±1 μm positional accuracy.

Material Properties: Highly reflective materials like copper require green lasers (532 nm) for better energy absorption.

Environmental Control: Stable temperature and vibration reduction maintain beam alignment.

What material limitations exist in laser processing?

Highly Reflective Materials: Copper and aluminum at 1.06 μm require green (532 nm) or UV lasers to improve energy absorption.

Brittle Materials: Ceramics and glass may crack with nanosecond lasers; ultrafast lasers reduce thermal stress.

What is the cost of laser processing equipment?

High-precision systems (e.g., femtosecond lasers) involve significant upfront investment but reduce waste and maintenance costs long-term.

Mid-power systems (e.g., fiber laser cutters) are more cost-effective for mass production (e.g., automotive panels).