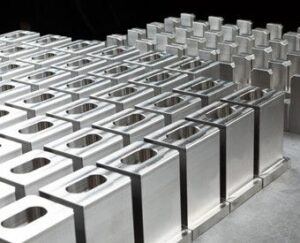

At Kesu, we specialize in low-volume CNC machining services for non-standard, high-precision components. With no minimum order quantity (MOQ) and a focus on small-batch production, we cater to industries requiring custom parts in materials such as Aluminium (5052, 6061, 7075), Titanium, Inconel 718, Stainless Steel (304, 316, 17-4PH), Ceramics, ABS, POM, PEEK, and more. Upload your 2D & 3D drawings, specify material, finish, and quantity, and get an instant quote today!

Why Choose Low-Volume CNC Machining?

Low-volume CNC machining is ideal for producing small quantities of complex, high-precision parts without the need for expensive tooling or mass production setups. This method is perfect for prototyping, custom components, and industries where flexibility and speed are critical.

Key Benefits of Low-Volume CNC Machining

- High Precision: Achieve tight tolerances as low as ±0.002 mm for metal parts and ±0.01 mm for plastics.

- No MOQ: Produce as few as one piece, ideal for prototypes or custom orders.

- Material Versatility: Work with metals like Aluminium, Titanium, and Stainless Steel, as well as plastics like PEEK and ABS.

- Fast Turnaround: CNC machining ensures quick production compared to traditional methods like rapid molding.

Applications of Low-Volume CNC Machining

Our services support industries such as aerospace, automotive, robotics, shipbuilding, and construction machinery. Common applications include:

- Prototypes for product development

- Custom components for specialized equipment

- High-precision parts for aviation and medical devices

Our CNC Machining Capabilities

Kesu is equipped with state-of-the-art CNC machines to handle complex geometries and tight tolerances. Our capabilities include 3-axis, 4-axis, 5-axis milling, CNC turning, and lathe-milling for low-volume production.

Machine Specifications

| Machine Type | Quantity | Brand | Max Part Size |

|---|---|---|---|

| 3-Axis CNC Machine | 50 | - | 1500 x 800 mm |

| 4-Axis CNC Machine | 20 | AutoCam | D600 x L1200 mm |

| 5-Axis CNC Machine | 10 | Jingdiao/DMG Mori | D600 mm |

| CNC Lathe Machine | 50 | Tsugami | D300 x L1200 mm |

| 5-Axis Lathe-Mill Machine | 1 | Mazak/DMG Mori | D300 x L1200 mm |

Tolerance Standards

| Feature | Tolerance (Metal, mm) | Tolerance (Plastic, mm) |

|---|---|---|

| Linear Dimensions | ±0.01 | ±0.05 |

| Diameter | ±0.002 | ±0.02 |

| Precise Hole | ±0.002 | ±0.02 |

| Straightness | ±0.002 | ±0.02 |

| Flatness | ±0.002 | ±0.01 |

Materials and Finishes

We offer a wide range of materials and surface finishes to meet your project requirements. Our expertise in machining difficult materials like Titanium and Inconel ensures high-quality results.

Available Materials

- Metals: Aluminium (5052, 6061, 7075), Stainless Steel (304, 316, 17-4PH), Titanium, Inconel 718, Magnesium, Brass, Copper, Tool Steel, Zinc.

- Plastics: ABS, POM, PEEK, Nylon, PC, PTFE, Delrin, HDPE, PMMA, PP.

- Others: Ceramics, SLS Nylon.

Surface Finish Options

- Anodizing (Standard and Hard)

- Electroplating (Zinc, Nickel, Chrome)

- Powder Painting, Teflon Coating

- Polishing, Sandblasting, Laser Marking

- Silk Screen, Passivation, DLC Coating

Quality Assurance

Our advanced inspection equipment ensures every part meets your specifications. We adhere to ISO 2768-F for metal parts and ISO 2768-M for plastic parts.

Inspection Equipment

| Equipment | Quantity | Brand |

|---|---|---|

| CMM | 2 | LEAD |

| XRF Spectrometer | 1 | HITACHI |

| Calliper | 20 | - |

| Micrometer | 10 | - |

FAQ: Low-Volume CNC Machining

What is low-volume CNC machining?

Low-volume CNC machining refers to the production of small quantities (1 to hundreds) of high-precision parts using computer numerical control (CNC) machines. It is ideal for prototypes, custom components, and industries requiring flexibility.

What materials can you machine?

We machine a variety of materials, including Aluminium, Titanium, Stainless Steel, Inconel 718, ABS, PEEK, Ceramics, and more. Contact us for specific material requirements.

What are your tolerance capabilities?

For metal parts, we achieve tolerances as tight as ±0.002 mm for diameters and holes. For plastics, tolerances can be as low as ±0.01 mm for flatness and parallelism.

How can I get a quote?

Upload your 2D & 3D drawings with material, finish, and quantity details on our website or email us for an instant quote.