Metal machining stands as a cornerstone of subtractive manufacturing, a process where material is systematically removed from a workpiece to achieve precise shapes, dimensions, and surface properties. Unlike additive manufacturing, which builds objects layer by layer, or formative processes that reshape material without removal, machining relies on cutting, grinding, or erosion to transform raw metal into functional components. This method’s ability to produce parts with tight tolerances—often measured in thousandths of an inch—makes it indispensable across critical industries.

Its significance spans aerospace, where turbine blades demand micron-level precision; automotive manufacturing, which relies on machined gears and engine components for performance; medical fields, where biocompatible implants require exacting specifications; and electronics, where miniature heat sinks and connectors depend on precise machining. Each industry benefits from the process’s versatility, accommodating everything from large structural parts to microscopic components.

A key distinction lies between traditional machining and modern techniques. Traditional methods, such as manual turning or milling, rely on skilled operators to guide tools, offering flexibility but limited precision and repeatability. In contrast, Computer Numerical Control (CNC) machining uses pre-programmed software to control tools, enabling consistent, high-accuracy production of complex geometries. This shift from human guidance to digital precision has revolutionized manufacturing, reducing errors and scaling production capabilities.

The evolution of machining mirrors humanity’s progress in engineering. From early manual lathes in the 18th century, which required immense skill to operate, to today’s automated CNC systems that run 24/7 with minimal oversight, the field has continuously advanced. Innovations like electric motors, high-speed steel tools, and computerization have each marked leaps forward, expanding what’s possible in terms of material handling, complexity, and efficiency. Today, machining remains a dynamic field, adapting to new technologies while retaining its core purpose: transforming metal into the building blocks of modern life.

History of Metal Machining

The roots of metal machining stretch back to the 18th century, a period when manual craftsmanship dominated manufacturing. Early machinists relied on hand-cranked lathes and files to shape metal, with skills passed down through apprenticeships. These tools, though primitive by modern standards, enabled the production of basic components for clocks, weapons, and early industrial machinery. The lathe, in particular, emerged as a foundational tool, allowing workers to rotate metal workpieces against stationary cutting tools to create cylindrical shapes—a principle still central to machining today.

The Industrial Revolution (late 18th to mid-19th century) catalyzed a transformation in machining. As demand for standardized parts grew, inventors developed mechanized machine tools. In 1797, Henry Maudslay’s precision lathe introduced the concept of interchangeable parts, a breakthrough that laid the groundwork for mass production. This innovation allowed components to be made to exact specifications, ensuring they fit together without manual fitting—a radical shift from the custom craftsmanship of the past. The 19th century also saw the development of milling machines, which used rotating cutters to shape metal, and drill presses, enabling the efficient creation of holes. These advancements fueled the growth of railways, steam engines, and factory machinery, driving industrialization worldwide.

Post-World War II, machining entered a new era of innovation. The war’s demand for complex, high-precision parts—such as aircraft engines and artillery components—spurred research into new techniques. Non-traditional machining methods emerged, including Electrical Discharge Machining (EDM), which uses electrical sparks to erode metal, allowing for the shaping of hard materials that resisted traditional cutting tools. The late 20th century brought the integration of computer control, with the first CNC machines appearing in the 1950s. By the 1970s, CNC technology had matured, replacing manual controls in many factories and enabling the production of intricate parts with unprecedented accuracy. This shift also highlighted the contrast between subtractive machining and emerging additive processes, such as 3D printing, though machining retained its dominance for high-precision, high-strength components.

Today, machining continues to evolve, with digitalization and automation driving its latest phase. The history of metal machining is not just a story of tools and techniques but of humanity’s ability to refine and innovate, turning raw metal into the precision components that power modern society.

Types of Metal Machining Processes

Traditional Machining Operations

Traditional machining processes rely on mechanical forces to remove material, using cutting tools to shape workpieces. These methods have been refined over centuries and remain widely used for their reliability and cost-effectiveness.

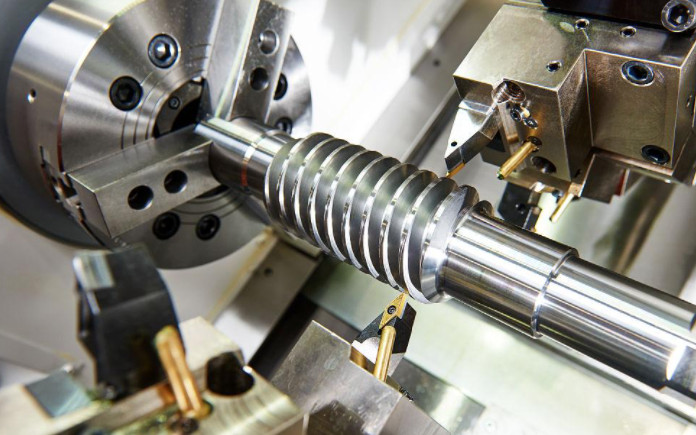

- Turning: Performed on a lathe, turning involves rotating the workpiece while a stationary cutting tool is fed into it, removing material to create cylindrical shapes. This process is ideal for producing shafts, bolts, gears, and sleeves. Advanced turning operations, such as taper turning or thread cutting, allow for the creation of conical surfaces or screw threads, expanding its versatility.

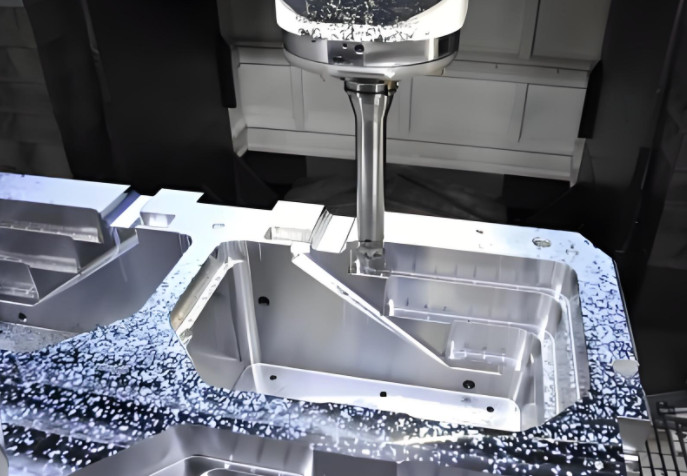

- Milling: Milling uses a rotating multi-point cutter to remove material from a stationary or moving workpiece. It excels at creating flat surfaces, slots, and complex contours. Face milling targets the top surface of a workpiece, while end milling uses the side of the cutter to create vertical or angular cuts. CNC milling machines can execute intricate 3D designs, making them essential for prototyping and custom parts.

- Drilling: The most common hole-making process, drilling uses a rotating drill bit to penetrate the workpiece. Drill presses provide stability and precision, ensuring holes are straight and evenly sized. Applications range from simple fastener holes in metal sheets to deep holes in engine blocks, with variations like countersinking and reaming used to prepare holes for screws or improve surface finish.

- Boring: Boring enlarges existing holes to achieve precise diameters and smooth surfaces, often used when drilling alone cannot meet tolerance requirements. It is critical for creating bearing seats or mating surfaces where a tight fit is essential, such as in engine cylinders.

- Grinding: A finishing process, grinding uses an abrasive wheel to remove small amounts of material, achieving exceptional surface finish and tight tolerances (as low as ±0.0001 inches). It is commonly used on hardened metals that resist cutting, such as tool steel, and is vital for precision components like bearing races and mold inserts.

- Sawing and Broaching: Sawing uses a toothed blade to cut metal into simple shapes or lengths, with band saws and circular saws handling everything from thin sheets to thick bars. Broaching, by contrast, uses a toothed tool (broach) pulled or pushed through a workpiece to create complex internal or external shapes, such as keyways or splines, in a single pass.

Non-Traditional Machining Techniques

Non-traditional processes bypass mechanical cutting, using thermal, electrical, or chemical energy to remove material. These methods excel at machining hard, brittle, or complex materials that challenge traditional tools.

- Electrical Discharge Machining (EDM): EDM uses controlled electrical sparks to erode material, working by creating a spark between an electrode and the workpiece in a dielectric fluid. It is ideal for intricate shapes, such as dies and molds, and can machine hardened metals without inducing stress. However, it is slower than cutting processes and limited by the electrode’s design.

- Waterjet Machining: This process uses high-pressure water (up to 90,000 psi) mixed with abrasives to cut through metal. It produces clean, burr-free edges and generates minimal heat, making it suitable for heat-sensitive materials like aluminum or titanium. Waterjet machining is versatile but slower for thick materials and requires significant energy to maintain pressure.

- Plasma and Laser Machining: Both use thermal energy to cut metal. Plasma cutting employs a high-temperature plasma arc to melt and blow away material, ideal for thick steel sheets. Laser machining uses a focused laser beam for precise, narrow cuts, often used in electronics for micro-components. While fast and accurate, these methods can leave heat-affected zones that alter material properties.

| Process Type | Examples | Advantages | Disadvantages |

| Traditional | Turning, Milling, Drilling | Cost-effective for simple parts; widely available equipment; fast for large volumes | Generates heat and waste; requires skilled operators; limited by material hardness |

| Non-Traditional | EDM, Waterjet, Laser | Handles hard/brittle materials; minimal tool wear; precise for complex shapes | Slower for large volumes; higher equipment costs; limited material thickness (laser/waterjet) |

Materials Used in Metal Machining

The choice of material in metal machining significantly impacts process efficiency, tool selection, and final part performance. Machinists must balance properties like machinability, strength, and cost to meet application requirements.

Common metals include:

- Aluminum: Valued for its lightweight nature and excellent machinability, aluminum is easy to cut, produces smooth surfaces, and generates minimal tool wear. Its low melting point requires careful cooling to prevent deformation, but its versatility makes it ubiquitous in aerospace, automotive, and consumer electronics.

- Stainless Steel: Known for corrosion resistance and strength, stainless steel comes in various grades, with austenitic types (e.g., 304) offering better machinability than martensitic grades (e.g., 440C). It tends to work-harden during machining, requiring sharp tools and slower feed rates to avoid tool damage.

- Titanium: Prized for its high strength-to-weight ratio and biocompatibility, titanium is challenging to machine due to its low thermal conductivity, which traps heat at the tool-workpiece interface. Specialized carbide tools and coolants are necessary, making it more expensive to process—though its use in aerospace and medical implants justifies the cost.

- Brass and Copper: These non-ferrous metals are highly machinable, with brass producing fine chips and smooth finishes. Their excellent conductivity makes them ideal for electrical components, while their malleability suits decorative parts. However, they are softer than steel, requiring lower cutting forces to avoid distortion.

Factors influencing material choice include:

- Machinability: A measure of how easily a material can be cut, influenced by hardness, ductility, and thermal properties. Materials like brass rate high in machinability, while titanium and high-alloy steels rate low.

- Mechanical Properties: Strength, hardness, and fatigue resistance are critical for structural parts. For example, high-strength steel is used in automotive gears, while aluminum’s lightness benefits aircraft components.

- Cost: Raw material and machining costs must align with budget constraints. Aluminum is often cheaper to machine than titanium, making it preferable for non-critical parts.

Exotic alloys present unique challenges. Inconel, a nickel-chromium superalloy used in jet engines, resists high temperatures but is extremely hard on tools, requiring slow speeds and specialized inserts. Tool steel, used for dies and cutting tools, is heat-treated to high hardness, demanding grinding rather than cutting for final shaping. Machining these materials requires advanced techniques and tools, increasing production time and cost—but their performance in extreme environments makes them irreplaceable in certain applications.

Tools and Cutting Conditions

The success of metal machining depends on selecting the right tools and optimizing cutting conditions, which directly affect precision, efficiency, and tool life.

Cutting Tools

Cutting tools are classified by their design and material. Single-point tools, used in turning and boring, have a single cutting edge and are often made of high-speed steel (HSS) or carbide. HSS tools are cost-effective for low-speed machining of soft metals, while carbide inserts—tough, wear-resistant, and able to withstand high temperatures—are preferred for high-speed machining of hard materials like stainless steel.

Multi-point tools, such as milling cutters and drill bits, feature multiple cutting edges. They are typically made of carbide or coated with materials like titanium nitride (TiN) to reduce friction and extend life. Specialty tools, like diamond-tipped cutters, are used for ultra-hard materials or when mirror-like surface finishes are required.

Cutting Parameters

Three key parameters determine machining performance:

- Cutting Speed (v): The speed at which the tool’s cutting edge moves relative to the workpiece, measured in surface feet per minute (SFM). Higher speeds increase productivity but generate more heat, risking tool wear or workpiece damage.

- Feed Rate (f): The distance the tool advances into the workpiece per revolution (for turning) or per tooth (for milling), measured in inches per revolution (IPR) or inches per tooth (IPT). A higher feed rate removes more material quickly but can reduce surface finish quality.

- Depth of Cut (d): The thickness of material removed in one pass, measured in inches. Deeper cuts require more power and increase tool stress, while shallow cuts are better for finishing operations.

These parameters are interdependent: increasing one often requires adjusting others to maintain balance. For example, machining aluminum (soft) allows higher cutting speeds and feed rates than machining titanium (hard), where slower speeds and shallower cuts prevent tool failure.

Material Removal Rate (MRR)

MRR quantifies the volume of material removed per unit time, calculated as:

**\( R_{MR} = v \times f \times d \)

Where:

- \( v \) = cutting speed (in/min),

- \( f \) = feed rate (in/rev),

- \( d \) = depth of cut (in).

A higher MRR indicates faster production but must be balanced with tool life and surface finish requirements.

Safety and Maintenance

Tool wear is inevitable, but monitoring for signs like chipping, dullness, or excessive heat helps prevent unexpected failures. Coolant systems are critical, as they reduce heat, lubricate the cutting zone, and flush away chips—extending tool life and improving surface finish.

Personal protective equipment (PPE) is essential: safety glasses shield against flying chips, gloves protect hands from sharp edges, and hearing protection guards against loud machinery. Regular equipment maintenance, such as aligning tools and checking for loose components, ensures consistent performance and reduces accident risks.

CNC Machining: The Modern Standard

Computer Numerical Control (CNC) machining has revolutionized manufacturing by replacing manual tool operation with pre-programmed software, enabling unprecedented precision and efficiency. At its core, CNC uses G-code—a standardized language that translates design specifications into precise tool movements. This code dictates every aspect of the process, from cutting speed and feed rate to tool changes, ensuring each part matches the digital blueprint exactly.

The benefits of CNC machining are transformative:

- Precision: CNC systems achieve tolerances as tight as ±0.0001 inches, far exceeding manual capabilities. This accuracy is critical for aerospace components, medical implants, and other applications where even minor deviations can cause failure.

- Repeatability: Once programmed, a CNC machine produces identical parts batch after batch, eliminating variations caused by human error. This consistency is vital for mass production, where interchangeability is essential.

- Complexity: CNC machines handle intricate geometries—such as 3D contours or undercuts—that would be impossible or impractical to produce manually. Multi-axis CNC machines (e.g., 5-axis models) rotate the workpiece or tool along multiple axes, enabling the creation of highly complex parts in a single setup.

- Efficiency: CNC systems operate 24/7 with minimal supervision, reducing downtime and increasing production output. Automated tool changers further streamline processes, allowing one machine to perform multiple operations (e.g., milling, drilling, tapping) without manual intervention.

CNC’s applications span industries. In aerospace, it produces turbine blades with aerodynamic profiles that maximize fuel efficiency. In medicine, it machines titanium implants with porous surfaces that integrate with bone tissue. Even in custom fabrication, CNC enables rapid prototyping, allowing designers to test and refine parts quickly.

Compared to manual machining, CNC offers clear advantages. Manual machining relies on skilled operators to guide tools, making it slow and prone to human error—suitable for simple parts or small batches but impractical for complex, high-volume production. CNC, by contrast, thrives in these scenarios, combining speed, accuracy, and scalability. While initial setup costs are higher—due to software, training, and machine investment—the long-term savings in labor and scrap make it the standard for modern manufacturing.

As technology advances, CNC continues to evolve, integrating with artificial intelligence and IoT sensors to optimize processes in real time. Yet its core value remains unchanged: turning digital designs into physical reality with unmatched precision.

Applications and Industries

Metal machining’s versatility makes it indispensable across a diverse range of industries, each relying on its ability to produce precise, durable components tailored to specific needs.

Automotive Industry

The automotive sector depends on machining for critical components that ensure performance and safety. Engine parts, such as crankshafts and camshafts, require tight tolerances to maintain proper lubrication and combustion efficiency. Transmission gears, machined to precise tooth profiles, enable smooth power transfer, while brake rotors and calipers rely on flat, parallel surfaces to ensure consistent braking. Machining also produces chassis components, such as suspension brackets, which must withstand heavy loads and vibration—demanding high-strength materials and accurate shaping.

Aerospace Industry

Aerospace applications push machining to its limits, requiring parts that balance light weight with extreme strength. Turbine blades, machined from heat-resistant superalloys, must withstand temperatures exceeding 1,000°C while maintaining aerodynamic precision. Structural components, such as wing spars and fuselage frames, are often machined from aluminum or titanium alloys to reduce weight without sacrificing durability. Landing gear parts, subjected to enormous stress during takeoff and landing, depend on machining to achieve fatigue-resistant surfaces and precise fits.

Medical Industry

In medicine, machining produces components that interact directly with the human body, demanding biocompatibility and exacting precision. Surgical instruments, such as scalpels and forceps, require sharp edges and smooth finishes to minimize tissue damage. Implants—including artificial hips, knees, and dental fixtures—are machined from titanium or stainless steel, with porous surfaces that promote bone integration. Machining also creates components for medical devices, such as MRI machine frames or pacemaker housings, where accuracy ensures reliable operation.

Electronics Industry

The electronics sector relies on machining for small, precise parts that enable device functionality. Heat sinks, machined from aluminum or copper, dissipate heat from microchips, preventing overheating. Connectors and terminals, often made of brass or copper, require tight tolerances to ensure secure electrical connections. Enclosures for smartphones, laptops, and industrial equipment are machined to fit components snugly while providing protection—with finishes ranging from matte to high-gloss.

Emerging Applications

Metal machining is expanding into new frontiers, including renewable energy and robotics. Wind turbine hubs and solar panel mounting brackets require large, precisely machined parts to withstand outdoor conditions. Robotics relies on machined gears, joints, and structural components for smooth movement and durability.

Metal Machining FAQ

What is metal machining?

Metal machining is the process of removing material from a metal workpiece to create a desired shape, size, or finish using tools like lathes, mills, drills, or CNC machines. It includes processes like turning, milling, drilling, grinding, and more.

What is CNC machining?

CNC (Computer Numerical Control) machining uses computer programs to control machine tools, enabling precise, automated, and repeatable operations. It’s widely used for complex parts and high-volume production.

How can I reduce machining costs?

Optimize design: Simplify part geometry to minimize machining time and tool changes.

Material selection: Choose materials that are easier to machine (e.g., aluminum over titanium).

Batch production: Increase batch sizes to spread setup costs.

Use CNC: Automate processes to reduce labor and errors.

Proper tooling: Select appropriate tools and maintain them to avoid rework.

How does machining differ from 3D printing?

Machining: Subtractive, removes material from a solid block; ideal for high precision and strong materials.

3D Printing: Additive, builds parts layer by layer; better for complex geometries but limited by material strength and surface finish.

How do I choose the right machining process?

Material: Harder materials may require specific processes (e.g., grinding or EDM).

Part complexity: Complex shapes may need CNC milling or 5-axis machining.

Tolerances: Tighter tolerances require precision processes like CNC or grinding.

Volume: High volumes favor CNC for efficiency; low volumes may use manual methods.

Budget: Balance cost with required quality and production speed.