Choosing the right machining process is essential for achieving high-quality results in manufacturing. Milling and grinding are two prominent material removal techniques, each suited to specific applications based on their mechanics, capabilities, and limitations. This article provides a detailed, technical comparison of milling and grinding, focusing on their processes, parameters, and practical considerations. The content is designed to reflect expertise, reliability, technical depth, professionalism, and a systematic approach, offering manufacturing professionals a clear framework for decision-making.

Milling Process: Mechanics and Characteristics

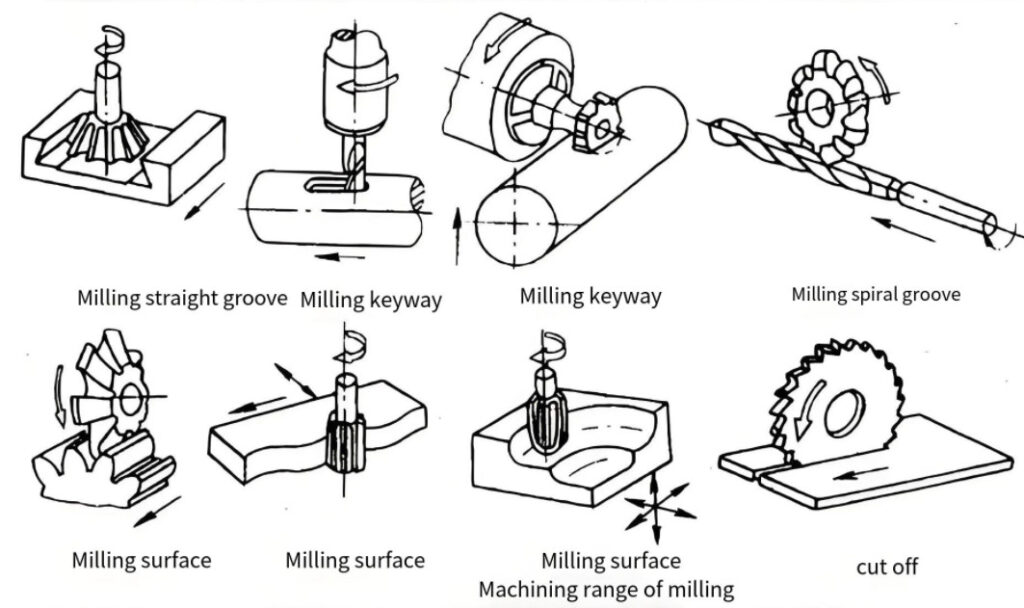

Milling involves removing material from a workpiece using a rotating multi-point cutting tool, such as an end mill or face mill. The tool’s cutting edges engage the workpiece, which is typically secured on a movable table, allowing for precise material removal. Milling is widely used in industries like aerospace, automotive, and mold manufacturing due to its versatility in creating complex geometries.

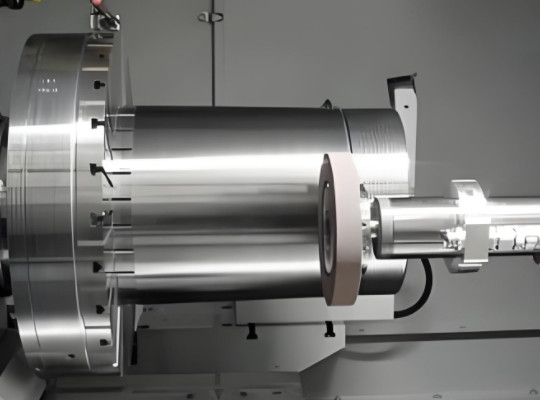

Milling operations can be performed on vertical or horizontal milling machines, often controlled by computer numerical control (CNC) systems for enhanced precision. Key milling parameters include:

- Cutting Speed (Vc): Ranges from 50–400 m/min, e.g., 100–150 m/min for steel and 250–400 m/min for aluminum.

- Feed Rate (f): Typically 0.05–0.2 mm/tooth for roughing and 0.01–0.05 mm/tooth for finishing.

- Depth of Cut (ap): Varies from 1–6 mm for rough milling and 0.2–1 mm for finishing.

- Tool Material: Includes high-speed steel (HSS), carbide, or coated tools for improved wear resistance.

Milling is effective for producing features like slots, pockets, and contoured surfaces. It handles a broad range of materials, from soft metals like copper to tougher alloys like stainless steel. However, milling generates significant cutting forces, which may cause deflection in thin or flexible workpieces, affecting accuracy.

Grinding Process: Mechanics and Characteristics

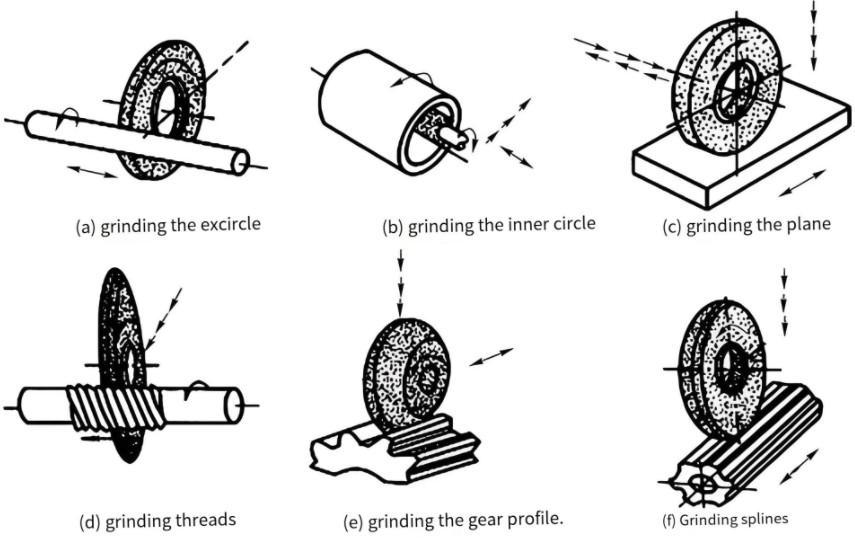

Grinding is a precision machining process that uses an abrasive wheel to remove small amounts of material, achieving high accuracy and smooth surface finishes. The wheel, composed of abrasive grains bonded together, acts as thousands of micro-cutting tools. Grinding is commonly used in toolmaking, automotive, and precision engineering, especially for finishing hardened materials.

Grinding operations include surface grinding, cylindrical grinding, and centerless grinding, each tailored to specific workpiece shapes. Key grinding parameters include:

- Wheel Speed (Vs): Typically 25–50 m/s, with high-speed grinding up to 100 m/s.

- Workpiece Speed (Vw): Ranges from 0.2–1.5 m/min for surface grinding and 0.1–0.8 m/min for cylindrical grinding.

- Depth of Cut (ae): Small, typically 0.002–0.03 mm per pass to control heat and maintain precision.

- Wheel Material: Common abrasives include aluminum oxide, silicon carbide, and cubic boron nitride (CBN) for hard materials.

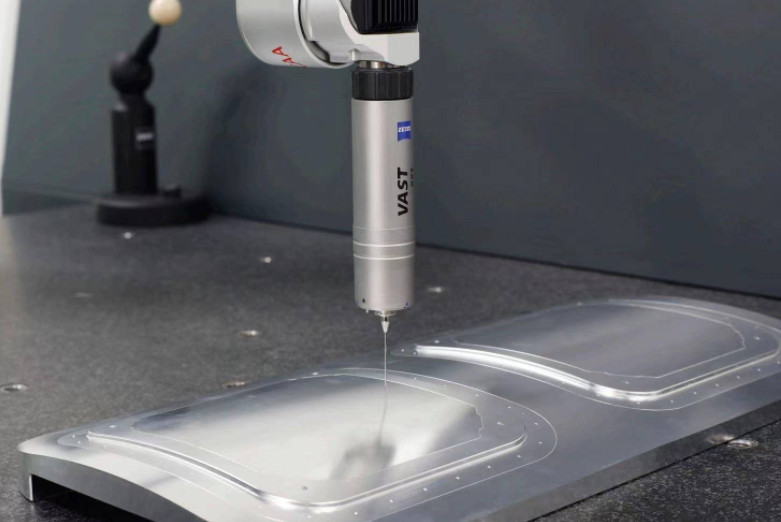

Grinding achieves tight tolerances (e.g., ±0.003 mm) and surface roughness values as low as Ra 0.2–0.6 µm. It is ideal for hard materials like tool steel (above 50 HRC) or ceramics, but its low material removal rate makes it unsuitable for roughing operations. Heat generation during grinding necessitates effective coolant systems to prevent thermal damage.

Comparative Analysis of Milling and Grinding

Milling and grinding differ significantly in their mechanisms, capabilities, and applications. The following table outlines their key distinctions:

| Parameter | Milling | Grinding |

|---|---|---|

| Tool Type | Multi-point cutting tool | Abrasive wheel |

| Material Removal Rate | High (100–600 cm³/min) | Low (0.5–15 cm³/min) |

| Surface Finish | Ra 1.6–6.3 µm | Ra 0.2–0.8 µm |

| Tolerance | ±0.02–0.1 mm | ±0.003–0.01 mm |

| Material Suitability | Soft to medium-hard (up to 40 HRC) | Hard (above 50 HRC) |

| Heat Generation | Moderate | High, requires coolant |

This comparison highlights milling’s strength in high material removal and versatility, contrasted with grinding’s superiority in precision and surface quality.

Applications of Milling and Grinding

The suitability of milling or grinding depends on the workpiece requirements and industry application. Below are their primary uses:

Milling Applications: Milling is ideal for creating complex features and removing large material volumes. Common applications include:

- Aerospace components (e.g., wing spars, engine mounts)

- Automotive parts (e.g., cylinder heads, gearboxes)

- Prototypes and molds for plastic injection

For example, a CNC milling machine can produce a steel mold cavity with a tolerance of ±0.05 mm using a 40 mm carbide face mill at 120 m/min cutting speed and 3 mm depth of cut, completing the roughing phase in under 10 minutes.

Grinding Applications: Grinding is primarily a finishing process for high-precision components. Typical applications include:

- Precision tools (e.g., drills, milling cutters)

- Automotive parts (e.g., valve stems, bearings)

- Hardened components requiring tight tolerances

For instance, cylindrical grinding can achieve a roundness tolerance of ±0.004 mm on a hardened steel shaft using a CBN wheel at 40 m/s, with a surface finish of Ra 0.3 µm.

Selection Criteria for Milling vs. Grinding

Selecting between milling and grinding requires evaluating several technical and practical factors. The following criteria provide a structured approach:

- Material Properties: Milling suits materials with hardness up to 40 HRC, such as aluminum or mild steel. Grinding is preferred for harder materials like quenched steel (50–60 HRC) or ceramics.

- Precision Requirements: Grinding is necessary for tolerances below ±0.01 mm or surface finishes below Ra 0.8 µm. Milling is adequate for tolerances above ±0.02 mm.

- Production Volume: Milling is faster and more cost-effective for low to medium volumes. Grinding is justified for high-volume production of precision components.

- Equipment Availability: Milling machines are more common and less costly than precision grinders. However, grinding wheels require regular dressing, increasing maintenance costs.

- Thermal Considerations: Grinding’s high heat generation requires coolant flow rates of 15–25 L/min to prevent workpiece damage. Milling produces less heat, often manageable with minimal coolant.

For example, milling is suitable for roughing a titanium aerospace bracket with a tolerance of ±0.1 mm, while grinding is better for finishing a hardened steel gear with a tolerance of ±0.005 mm.

Limitations and Practical Considerations

Both milling and grinding have inherent limitations that must be addressed to ensure optimal performance:

Milling Limitations:

- Tool Deflection: High cutting forces can cause tool deflection, reducing accuracy in deep or narrow features. Using shorter tools or lower feed rates (e.g., 0.03 mm/tooth) can mitigate this.

- Surface Finish Constraints: Milling typically achieves Ra 1.6–6.3 µm, which may require secondary finishing for precision applications.

Grinding Limitations:

- Slow Material Removal: Grinding’s low depth of cut (0.002–0.03 mm) results in longer cycle times, making it impractical for bulk material removal.

- Wheel Wear: Abrasive wheels degrade over time, requiring frequent dressing to maintain accuracy, which increases operational costs.

- Thermal Damage Risk: Improper coolant application can cause surface burns or cracks, particularly in sensitive materials like high-carbon steel.

These limitations emphasize the importance of aligning process selection with project requirements to avoid inefficiencies or quality issues.

Decision-Making Framework

To streamline process selection, the following table summarizes when to choose milling or grinding based on critical factors:

| Factor | Milling Preference | Grinding Preference |

|---|---|---|

| Material Hardness | Up to 40 HRC | Above 50 HRC |

| Tolerance | ±0.02–0.1 mm | ±0.003–0.01 mm |

| Surface Finish | Ra 1.6–6.3 µm | Ra 0.2–0.8 µm |

| Production Speed | High-volume roughing | Low-volume finishing |

| Geometry | Complex (e.g., slots, contours) | Simple (e.g., flat, cylindrical) |

This framework enables manufacturers to match project specifications with the appropriate process. For instance, milling is optimal for producing a brass prototype with complex features, while grinding is better for finishing a ceramic bearing with high precision.

Conclusion

Milling and grinding are essential machining processes with distinct strengths and applications. Milling offers high material removal rates and versatility for complex geometries, making it ideal for roughing and medium-precision tasks. Grinding provides unmatched precision and surface quality, particularly for hard materials and finishing operations. By evaluating material properties, tolerance requirements, production volumes, and equipment constraints, manufacturers can select the most suitable process to optimize efficiency and quality. This systematic approach ensures reliable, high-performance outcomes in diverse manufacturing scenarios.