Molecular pumps are critical components in semiconductor manufacturing, enabling high-vacuum environments for processes like wafer production, thin-film deposition, and etching. The impeller, a core element of these pumps, requires ultra-high precision machining to ensure performance, reliability, and compatibility with stringent industry standards. This guide provides a comprehensive overview of the machining precision requirements for molecular pump impellers, focusing on technical specifications, materials, processes, and quality control.

Overview of Molecular Pump Impellers in Semiconductor Applications

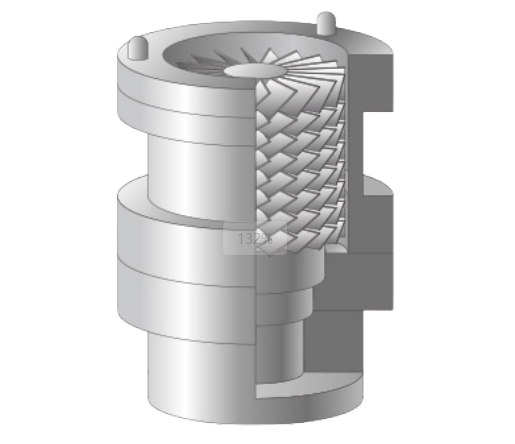

Molecular pump impellers are high-speed rotating components designed to transfer momentum to gas molecules, creating a high-vacuum environment. In semiconductor manufacturing, these pumps maintain vacuum levels between 10⁻¹ and 10⁻² mbar for processes such as crystal growth, chemical vapor deposition (CVD), and atomic layer deposition (ALD). The impeller’s complex geometry, consisting of multi-layer blades with micron-level clearances, demands exceptional machining precision to achieve optimal pumping performance and durability.

The impeller typically features a rotor with dozens of blades arranged in multiple stages, each with a gap of approximately 0.1 mm between the rotating blades and the stator. Manufacturing tolerances at the micron level are essential to prevent collisions, reduce vibrations, and ensure efficient gas flow. The impeller’s design often includes integrated shafts and symmetrical structures to enhance strength and balance at rotational speeds exceeding 20,000 RPM.

Precision Machining Requirements for Impellers

Machining molecular pump impellers involves stringent precision requirements due to their complex geometries and high-speed operation. The following sections detail the key parameters, including tolerances, surface finish, and dimensional accuracy.

Tolerances and Dimensional Accuracy

Tolerances for molecular pump impellers are typically in the range of ±0.001 inches (±0.025 mm) or tighter, depending on the pump’s specifications. For critical features like blade thickness, diameter, and gap clearance, tolerances may reach sub-micron levels (±0.00025 inches or ±0.006 mm). These tight tolerances ensure proper alignment, minimize imbalance, and prevent contact between rotating and stationary components.

Dimensional accuracy is critical for the impeller’s outer and inner diameters, which directly affect the pump’s compression ratio and vacuum performance. For example, a typical impeller may have an outer diameter of 5 inches (127 mm) with a tolerance of ±0.0005 inches (±0.0127 mm). Blade height, often around 0.5 inches (12.7 mm), requires similar precision to maintain consistent fluid dynamics.

Surface Finish Specifications

Surface finish is a key factor in impeller performance, as it affects gas flow efficiency and resistance to wear. A smooth surface reduces turbulence and enhances corrosion resistance in harsh semiconductor environments. The required surface finish is typically 32 RMS (Root Mean Square) or better, with some applications demanding 16 RMS or finer. For internal blade surfaces, abrasive flow machining (AFM) or electropolishing may be used to achieve surface roughness values as low as 8 RMS.

Table 1 below summarizes typical tolerance and surface finish requirements for molecular pump impellers:

| Parameter | Specification | Notes |

|---|---|---|

| Tolerance (General) | ±0.001 inches (±0.025 mm) | Applies to overall dimensions |

| Tolerance (Critical Features) | ±0.00025 inches (±0.006 mm) | For blade thickness, gap clearance |

| Surface Finish (External) | 32 RMS | Standard for most surfaces |

| Surface Finish (Internal Blades) | 16–8 RMS | Achieved via AFM or electropolishing |

Balancing and Vibration Control

Impellers must be dynamically balanced to prevent vibrations that could damage the pump or reduce its lifespan. Balancing is performed according to ISO 1940-1 standards, typically achieving a G2.5 balancing class for small impellers. This requires unbalance measurements at speeds up to 2200 RPM, with mass removal as low as 72.8 mg to meet tolerances of 0.1 g·mm. Precision machining ensures uniform material distribution, reducing the need for extensive post-processing balancing.

Materials for Molecular Pump Impellers

The choice of material for impellers is critical due to the high rotational speeds, corrosive gases, and vacuum conditions in semiconductor processes. Common materials include aluminum alloys, stainless steel, and advanced composites like carbon fiber.

Aluminum Alloys

Aluminum alloys, such as 6061-T651, are widely used due to their lightweight properties, machinability, and corrosion resistance. These alloys are ideal for impellers operating at high speeds, as they reduce inertia and improve energy efficiency. Typical impeller weight ranges from 0.95 kg to 4.25 kg, depending on size and design. Machining processes for aluminum include high-speed milling and wire EDM, achieving tolerances as tight as ±0.00025 inches (±0.006 mm).

Stainless Steel and Inconel

For applications involving corrosive gases, stainless steel (e.g., 347) or Inconel is preferred. These materials offer superior durability but pose machining challenges due to their hardness. CNC machines with high-torque spindles and live tooling are used to handle these materials, ensuring true position accuracy of 0.03 mm or better. Stainless steel impellers are common in pumps for etching and CVD processes, where chemical resistance is paramount.

Carbon Fiber Composites

Carbon fiber is used in advanced molecular pumps to reduce weight and enhance strength. The rotor structure often includes a carbon fiber tube integrated with a metal shaft. Machining carbon fiber requires ultra-precision assembly to maintain spiral channel dimensions, with tolerances as low as ±0.01 mm. This material is particularly suited for compact, high-performance pumps in portable analytical instruments.

Machining Processes for Impellers

The complexity of impeller geometries necessitates advanced machining processes, primarily CNC machining, supplemented by specialized techniques like wire EDM and additive manufacturing.

5-Axis CNC Machining

5-axis CNC machining is the primary method for manufacturing molecular pump impellers due to its ability to handle complex 3D geometries. These machines offer flexibility in tool orientation, reducing setup times and ensuring precision for multi-blade designs. Key parameters include:

- Tool Path Optimization: CAM software generates smooth tool paths to minimize machining errors and achieve tolerances of ±0.025 mm.

- Spindle Speed: Up to 20,000 RPM for aluminum, with lower speeds (10,000–15,000 RPM) for stainless steel.

- Cutting Tools: Carbide or diamond-coated tools for high wear resistance.

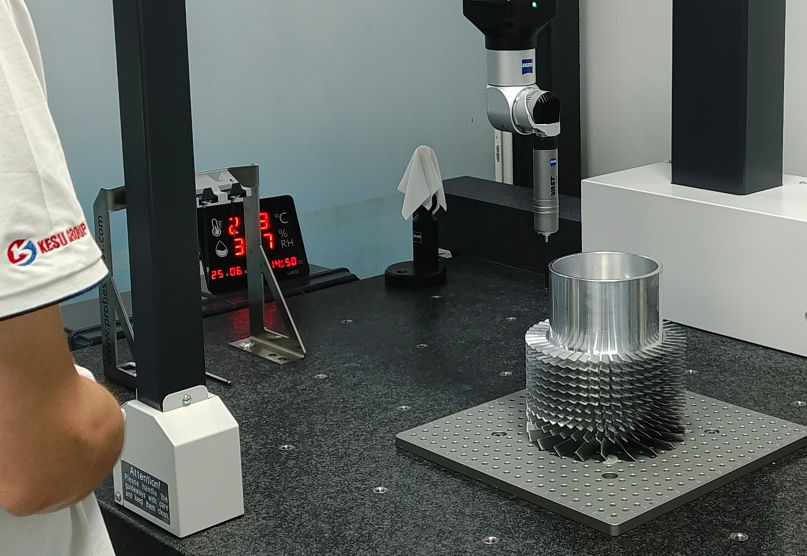

5-axis machines are equipped with Zeiss inspection systems to verify dimensions, ensuring compliance with ISO 9001 and AS9100 standards.

Wire EDM and High-Speed Milling

Wire electrical discharge machining (EDM) is used for ultra-precision features, such as blade profiles with squareness tolerances of 0.0005 inches (0.0127 mm). High-speed milling complements EDM by removing material efficiently during roughing and semi-finishing phases. These processes achieve surface finishes of 32 RMS or better, critical for impeller performance.

Additive Manufacturing and Post-Processing

Additive manufacturing, such as laser powder bed fusion (LPBF), is used for prototyping or producing complex impeller designs. LPBF impellers, made from materials like IN 625, require post-machining to achieve final tolerances and surface finishes. For example, a closed impeller may undergo 5-axis CNC milling after LPBF to correct distortions and ensure dimensional accuracy.

Quality Control and Inspection

Quality control is integral to impeller manufacturing, given the semiconductor industry’s stringent requirements. Inspection processes ensure compliance with design specifications and operational reliability.

Inspection Techniques

Coordinate measuring machines (CMMs) and laser scanners verify dimensional accuracy, with resolution down to 0.001 mm. Zeiss inspection equipment is commonly used to measure critical features like blade angles and gap clearances. Non-destructive testing (NDT), such as X-ray or ultrasonic inspection, detects internal defects in welded or additively manufactured impellers.

Balancing and Performance Testing

Dynamic balancing is performed using machines like the Passio 5, operating at 2200 RPM to achieve G2.5 standards. Performance testing involves simulating vacuum conditions to verify pumping speed and compression ratios. For example, a molecular pump may be tested at 10⁻² mbar to ensure stable operation under high front-stage pressure.

Key Considerations in Impeller Machining

Several factors influence the success of impeller machining, including material selection, process optimization, and equipment reliability. The following table outlines common considerations and their impact:

| Consideration | Impact | Mitigation |

|---|---|---|

| Material Hardness | Increases tool wear, affects machining time | Use carbide or diamond-coated tools |

| Complex Geometries | Requires multiple setups, risks errors | Employ 5-axis CNC machining |

| Thermal Expansion | Alters dimensions during machining | Control shop temperature, use coolant |

Conclusion

Precision machining of molecular pump impellers for the semiconductor industry requires advanced technologies, stringent tolerances, and rigorous quality control. By leveraging 5-axis CNC machining, wire EDM, and additive manufacturing, manufacturers can achieve the micron-level precision needed for high-vacuum applications. Materials like aluminum, stainless steel, and carbon fiber are selected based on performance requirements, while inspection and balancing ensure reliability. Adhering to these standards enables the production of impellers that meet the demanding needs of semiconductor processes, ensuring efficient and consistent vacuum performance.