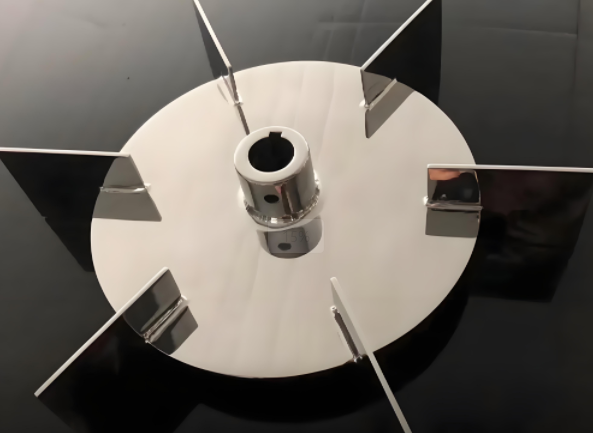

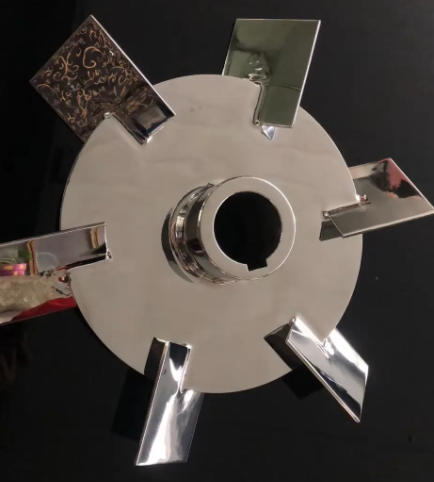

High-temperature alloy impellers, critical components in aerospace, power generation, and industrial applications, require precise surface finishing after heat treatment to achieve optimal performance. The heat treatment process enhances mechanical properties like strength and creep resistance, but it often leaves surface imperfections such as oxide layers, scale, or roughness. Surface polishing is essential to restore smoothness, improve corrosion resistance, and ensure dimensional accuracy. This guide outlines the key points of the polishing process for heat-treated high-temperature alloy impellers, focusing on technical procedures, parameters, and practical considerations to ensure high-quality outcomes.

Heat Treatment Effects on High-Temperature Alloy Impellers

High-temperature alloys, such as nickel-based superalloys (e.g., Inconel, Hastelloy) or titanium alloys (e.g., Ti-6Al-4V), are subjected to heat treatment processes like solution treatment, quenching, and aging to optimize their microstructure. These processes, while improving hardness and strength, can introduce surface challenges:

- Oxide Layer Formation: Heating in non-vacuum or non-inert atmospheres leads to oxide films, which can be light yellow, blue, or gray, depending on the temperature and alloy composition.

- Surface Roughness: Heat treatment, especially quenching, may cause surface irregularities due to thermal stresses or phase transformations.

- Scale and Discoloration: Residual scale from high-temperature exposure can adhere to the surface, requiring removal for functional and aesthetic purposes.

These surface conditions necessitate a systematic polishing process to achieve a smooth, defect-free finish while preserving the impeller’s dimensional integrity and mechanical properties.

Surface Preparation Before Polishing

Effective polishing begins with proper surface preparation to remove heat treatment-induced defects. The preparation steps are critical to ensure the polishing process is efficient and does not compromise the impeller’s microstructure.

Cutting and Sectioning

Cutting is often required to remove excess material or prepare the impeller for inspection. For high-temperature alloys, use resin-bonded cubic boron nitride (CBN) or aluminum oxide cut-off wheels to minimize thermal damage. Key parameters include:

- Cutting speed: 20–30 m/s to reduce heat generation.

- Coolant: Continuous water-based coolant to prevent microstructural changes.

- Feed rate: 0.05–0.1 mm/s for precise cuts without excessive force.

Avoid excessive pressure to prevent cracking or distortion, especially in complex impeller geometries.

Mounting

For small or fragile impeller sections, mounting standardizes geometry for easier handling during polishing. Cold mounting with low-shrinkage epoxy or acrylic resins (e.g., KM-B or KM-U) is preferred to avoid thermal stress. Parameters include:

- Resin curing time: 8–12 hours at room temperature.

- Mold diameter: 25–50 mm, depending on impeller size.

- Vacuum impregnation: Applied to fill surface cracks or pores, ensuring resin adhesion.

Post-mounting, a brief grinding step with coarse abrasive paper (e.g., 180-grit SiC) removes the resin meniscus to ensure flatness.

Cleaning

Pre-polishing cleaning removes debris, cutting residues, or oils. Ultrasonic cleaning with ethanol for 5–10 minutes is effective, ensuring no abrasive particles remain that could contaminate the polishing process.

Polishing Techniques for High-Temperature Alloy Impellers

Polishing high-temperature alloy impellers involves multiple stages, progressing from coarse to fine abrasives to achieve a mirror-like finish. The choice of technique depends on the alloy type, surface condition, and desired finish. Common methods include mechanical polishing, chemical polishing, and abrasive jet polishing.

Mechanical Polishing

Mechanical polishing uses abrasive media to remove material incrementally. It is suitable for nickel-based and titanium alloys, providing precise control over surface finish. The process involves:

| Stage | Abrasive | Grit Size | Polishing Cloth | Lubricant | Time (min) | RPM |

|---|---|---|---|---|---|---|

| Plane Grinding | SiC or Diamond | 220–400 | Hard, non-woven | Water | 2–5 | 150–300 |

| Fine Grinding | Diamond | 9–15 µm | Medium resilience | Water-based | 3–7 | 100–200 |

| Final Polishing | Colloidal Silica | 0.02–1 µm | Soft, high-resilience | DP-Lubricant Red | 5–10 | 50–150 |

Key Parameters:

- Pressure: 10–20 N/cm² to avoid embedding abrasives into softer alloy matrices.

- Polishing direction: Overlapping, slow motion to prevent heat buildup.

- Inspection: Periodic checks with optical microscopy to ensure scratch-free surfaces.

For titanium alloys, use MD-Mezzo cloths to prevent abrasive embedding, while nickel-based alloys can tolerate MD-Largo cloths for faster material removal.

Chemical Polishing

Chemical polishing uses acidic or alkaline solutions to dissolve surface layers, ideal for delicate impeller geometries. For titanium alloys, a solution of 10% HF, 30% HNO₃, and 60% H₂O is effective, with parameters:

- Immersion time: 1–3 minutes at 20–30°C.

- Agitation: Gentle stirring to ensure uniform material removal.

- Rinse: Immediate water rinse to halt chemical reactions.

For nickel-based alloys, phosphoric acid-based solutions (e.g., 50% H₃PO₄, 25% H₂SO₄, 25% H₂O) are used at 40–50°C for 2–5 minutes. Chemical polishing reduces roughness but may round edges, requiring careful control.

Abrasive Jet Polishing (AJP)

AJP is effective for complex impeller geometries, using a mixture of abrasive particles (e.g., Al₂O₃, 10–50 µm) and fluid jetted at high pressure. Parameters include:

- Pressure: 0.5–2 MPa.

- Jet angle: 45–60° for optimal surface smoothing.

- Flow rate: 100–200 mL/min to balance material removal and surface quality.

AJP reduces surface roughness by up to 40% and is particularly effective for internal channels in impellers, minimizing differential pressure in operational conditions.

Key Considerations for Optimal Polishing

Several factors influence the success of the polishing process, requiring careful attention to maintain the integrity of the impeller.

Preserving Microstructure

High-temperature alloys contain carbides, inclusions, or precipitates critical to their performance. Excessive grinding or polishing can fracture primary carbides or pull out fine secondary carbides, degrading mechanical properties. Use low-pressure polishing (5–10 N/cm²) and fine abrasives (≤3 µm) for final stages to retain these features.

Edge Retention

Impeller blades often have thin, curved edges prone to rounding during polishing. Hot compression mounting with fiber-reinforced resins (e.g., DuroFast) or careful fixturing ensures edge preservation. Avoid prolonged chemical polishing, as it may erode sharp edges.

Thermal Damage Control

Excessive heat from grinding or polishing can alter the heat-treated microstructure, forming unwanted phases or residual stresses. Maintain wet polishing conditions with water-based lubricants and limit polishing time per stage to 5–10 minutes.

Surface Roughness Targets

The target surface roughness (Ra) for impellers typically ranges from 0.1–0.5 µm for optimal aerodynamic performance and corrosion resistance. Measure roughness using profilometry or atomic force microscopy (AFM) to verify compliance with specifications.

Post-Polishing Inspection and Quality Control

After polishing, rigorous inspection ensures the impeller meets performance standards. Common techniques include:

- Optical Microscopy: Detects scratches, pits, or embedded abrasives at 100–500x magnification.

- Scanning Electron Microscopy (SEM): Analyzes carbide distribution and surface defects at sub-micron levels.

- X-ray Diffraction (XRD): Verifies phase stability post-polishing, ensuring no unintended transformations.

- Hardness Testing: Confirms that polishing has not softened the surface (e.g., Vickers hardness ≥ 350 HV for nickel-based alloys).

Document all parameters and results for traceability, especially for aerospace or turbine applications where quality assurance is critical.

Process Optimization and Parameter Summary

The following table summarizes key polishing parameters for high-temperature alloy impellers, tailored to common alloys like Inconel 718 and Ti-6Al-4V:

| Process | Alloy | Abrasive/Medium | Key Parameters | Target Ra (µm) |

|---|---|---|---|---|

| Mechanical Polishing | Inconel 718 | Diamond, 1–9 µm | 100–200 RPM, 10–20 N/cm², 5–10 min | 0.1–0.3 |

| Chemical Polishing | Ti-6Al-4V | HF-HNO₃ solution | 20–30°C, 1–3 min, gentle agitation | 0.2–0.5 |

| Abrasive Jet Polishing | Both | Al₂O₃, 10–50 µm | 0.5–2 MPa, 45–60° angle, 100–200 mL/min | 0.1–0.4 |

Optimizing these parameters requires balancing material removal rate, surface quality, and preservation of mechanical properties. Regular calibration of equipment and adherence to standardized procedures ensure repeatability.

Conclusion

Surface polishing of heat-treated high-temperature alloy impellers is a critical process that demands precision, technical expertise, and systematic execution. By addressing heat treatment-induced surface defects through careful preparation, selecting appropriate polishing techniques, and adhering to optimized parameters, manufacturers can achieve mirror-like finishes with minimal compromise to the impeller’s integrity. The outlined procedures, supported by detailed parameters and quality control measures, provide a reliable framework for achieving high-performance impellers suitable for demanding applications.