Swiss machining delivers unparalleled precision for aerospace components, meeting stringent requirements for safety, reliability, and performance.

Introduction to Swiss Machining

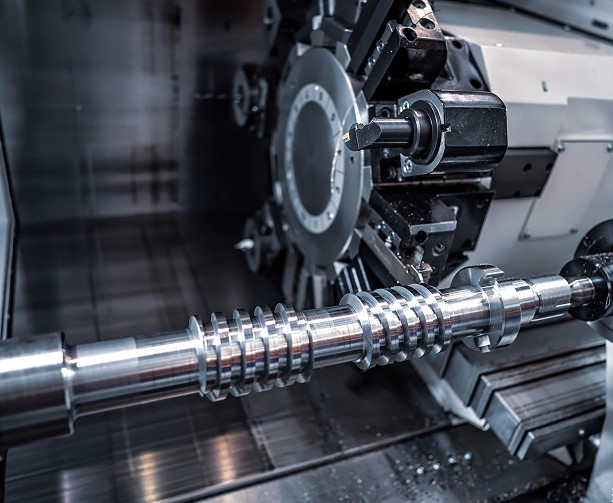

Swiss machining, also known as Swiss-style turning or Swiss CNC machining, is a high-precision manufacturing process designed to produce small, intricate parts with tight tolerances. Originating in Switzerland for watchmaking, it has become a cornerstone in aerospace manufacturing. The process uses a sliding headstock and guide bushing to support the workpiece, enabling exceptional accuracy and stability during machining. Aerospace applications demand components that meet exact specifications, and Swiss machining excels in delivering these requirements.

The process is performed on Swiss-type CNC lathes, which are equipped with multiple axes (typically 7–13) and can handle complex operations like turning, milling, drilling, and threading in a single setup. This capability reduces production time and ensures consistency, making it ideal for aerospace parts such as turbine blades, fuel injectors, and fasteners.

Key Features of Swiss Machining for Aerospace

Swiss machining is distinguished by several technical features that make it suitable for aerospace applications. These features ensure that components meet the industry’s rigorous standards for precision, reliability, and safety.

Sliding Headstock and Guide Bushing

The sliding headstock feeds the bar stock through a guide bushing, which supports the workpiece close to the cutting tool. This minimizes vibration and deflection, allowing for tolerances as tight as ±0.0001 inches (0.00254 mm). For aerospace parts like hydraulic fittings, this stability is critical to ensure consistent performance under high-pressure conditions.

Multi-Axis Capabilities

Swiss CNC machines can operate with up to 13 axes, enabling simultaneous operations such as turning, milling, and drilling. This reduces the need for multiple setups, ensuring dimensional accuracy and reducing production time. For example, a single Swiss machine can produce a complex aerospace fastener with cross-drilled holes and threaded features in one cycle.

High-Speed Spindles

Swiss lathes are equipped with high-speed spindles, often reaching speeds of 10,000–12,000 RPM. This allows for precise machining of small-diameter parts, such as aerospace sensor housings, with excellent surface finishes (up to 32 Ra). The high spindle speed also supports the use of small cutting tools, which are essential for intricate geometries.

Precision Advantages in Aerospace Applications

The aerospace industry requires components that withstand extreme conditions, including high temperatures, pressures, and vibrations. Swiss machining offers several precision advantages that address these demands.

Tight Tolerances

Swiss machining achieves tolerances as low as ±0.0002 inches (±0.005 mm), which is essential for aerospace components like jet engine parts. For instance, turbine blades require precise dimensions to ensure optimal airflow and fuel efficiency. The guide bushing and multi-axis control ensure that these tolerances are maintained across high-volume production runs.

Complex Geometries

Aerospace parts often feature intricate designs, such as fuel injector nozzles with multiple internal channels or landing gear components with threaded and milled features. Swiss machining can produce these geometries in a single operation, reducing the risk of errors associated with multiple setups. The ability to machine long, slender parts, such as actuator shafts, without deflection is particularly valuable.

Superior Surface Finishes

Surface finish is critical in aerospace to minimize friction and wear. Swiss machining delivers finishes as smooth as 16–32 Ra, reducing the need for secondary operations like polishing. For example, hydraulic system components benefit from smooth surfaces to ensure leak-free performance under high pressure.

Consistency and Repeatability

The automated nature of Swiss CNC machining ensures high repeatability, with every part meeting the same specifications. This is crucial for aerospace, where components like fasteners must be identical to ensure structural integrity. Swiss machines can produce thousands of parts with minimal variation, supporting both prototype and high-volume production.

Material Versatility for Aerospace Components

Aerospace manufacturing involves a wide range of materials, from lightweight alloys to heat-resistant superalloys. Swiss machining is compatible with these materials, ensuring flexibility and precision.

| Material | Properties | Aerospace Applications |

|---|---|---|

| Titanium | High strength-to-weight ratio, corrosion resistance | Fasteners, landing gear components |

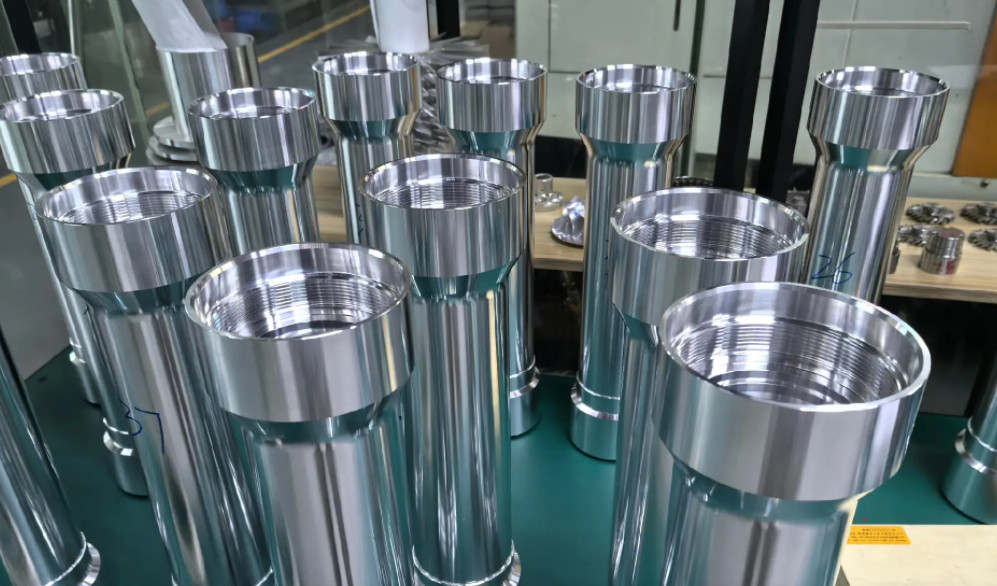

| Stainless Steel | Durability, corrosion resistance | Hydraulic fittings, sensor housings |

| Aluminum | Lightweight, machinability | Airframe components, connectors |

| Inconel | Heat resistance, high strength | Jet engine components, turbine blades, impellers |

Swiss machines can handle these materials with precision, even when machining small-diameter parts or complex features. For example, titanium fasteners require tight tolerances and smooth finishes to ensure reliability, and Swiss machining delivers both.

Applications of Swiss Machining in Aerospace

Swiss machining is used to produce a variety of aerospace components, each with specific requirements for precision and performance. Below are key applications.

Jet Engine Components

Jet engines rely on parts like turbine blades, fuel injectors, and compressor shafts, which require tight tolerances and heat-resistant materials. Swiss machining can produce these components with tolerances of ±0.0002 inches and surface finishes of 16 Ra, ensuring optimal performance and fuel efficiency.

Hydraulic and Pneumatic Systems

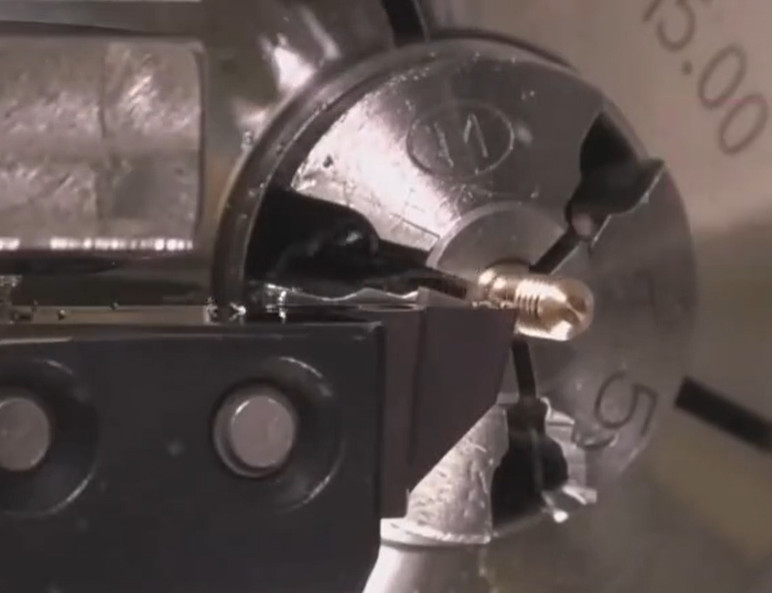

Hydraulic fittings and pneumatic valves must operate reliably under high pressure. Swiss machining produces these parts with precise internal threads and smooth surfaces, minimizing leaks and ensuring consistent performance. For example, a hydraulic fitting may require a tolerance of ±0.0001 inches for proper sealing.

Fasteners

Aerospace fasteners, such as bolts and screws, are critical for structural integrity. Swiss machining can produce fasteners with fine-pitched threads and tolerances of ±0.0003 inches, ensuring secure assembly and resistance to vibration.

Sensors and Connectors

Sensor housings and electrical connectors require intricate geometries and small diameters. Swiss machining supports the production of these parts with multi-axis operations, achieving tolerances of ±0.0002 inches and surface finishes of 32 Ra.

Efficiency and Cost-Effectiveness

Swiss machining offers efficiency advantages that contribute to cost-effectiveness in aerospace manufacturing.

Single-Setup Operations

By performing multiple operations in one setup, Swiss machining reduces production time and eliminates the need for secondary processes. This is particularly valuable for complex parts like fuel injectors, which may require turning, milling, and threading.

Material Waste Reduction

The precision of Swiss machining minimizes material waste, which is significant when working with expensive materials like titanium or Inconel. For example, a Swiss machine can produce a fastener with minimal excess material, reducing costs.

High-Volume Production

Swiss machines are optimized for high-volume runs, producing up to 30 parts per hour depending on complexity. This scalability ensures that aerospace manufacturers can meet tight production schedules without compromising quality.

Quality Assurance in Swiss Machining

Quality control is paramount in aerospace manufacturing. Swiss machining supports rigorous quality assurance through advanced technology and processes.

In-Process Inspections

Swiss CNC machines often include automated measuring systems that perform in-process inspections, ensuring that parts meet specifications. For example, a turbine blade may be checked for dimensional accuracy during machining to prevent defects.

Compliance with Standards

Aerospace manufacturers adhere to standards like AS9100 and ISO 9001. Swiss machining providers implement quality management systems to ensure compliance, delivering parts that meet industry requirements.

Traceability

Swiss machining facilities maintain detailed records of materials, processes, and inspections, ensuring traceability for every component. This is critical for aerospace applications, where part history may be required for regulatory purposes.

Conclusion

Swiss machining is a vital technology for aerospace manufacturing, offering precision, versatility, and efficiency. Its ability to achieve tight tolerances, produce complex geometries, and work with diverse materials makes it ideal for components like turbine blades, fasteners, and hydraulic fittings. By reducing production time, minimizing waste, and ensuring consistent quality, Swiss machining supports the aerospace industry’s demands for safety and reliability. For manufacturers seeking high-precision parts, Swiss machining remains a trusted and proven solution.

Frequently Asked Questions (FAQ): Swiss Machining in Aerospace

What is Swiss machining, and why is it important for aerospace?

Swiss machining (or Swiss turning/CNC machining) is a high-precision manufacturing process using specialized lathes with a sliding headstock and guide bushing. It excels at producing small, intricate parts with extremely tight tolerances. Originating for watchmaking, it's vital for aerospace because it meets the industry's demanding requirements for precision, reliability, and safety in critical components like turbine blades, fasteners, and fuel systems under extreme conditions.

What makes Swiss machines different from standard CNC lathes?

The key differentiators are:

Sliding Headstock & Guide Bushing: The bar stock feeds through a bushing that supports the workpiece very close to the cutting tool. This minimizes vibration and deflection, enabling exceptional precision (±0.0001 inches).

Multi-Axis Capability: Swiss machines often have 7-13 axes, allowing complex operations (turning, milling, drilling, threading) to be performed simultaneously in a single setup, improving accuracy and reducing production time.

Optimization for Small Parts: The design is ideal for machining long, slender, small-diameter parts common in aerospace.

What precision levels can Swiss machining achieve for aerospace parts?

Swiss machining consistently achieves incredibly tight tolerances, often as low as ±0.0001 inches (0.00254 mm) to ±0.0002 inches (0.005 mm). It also delivers superior surface finishes, typically in the range of 16-32 Ra, minimizing friction and wear and often eliminating the need for secondary polishing.

How does Swiss machining handle complex aerospace part geometries?

The multi-axis capability (up to 13 axes) allows intricate features like internal channels (fuel injector nozzles), cross-drilled holes, threads, and milled surfaces to be machined in a single operation. This "done-in-one" approach reduces handling errors, ensures dimensional accuracy between features, and is crucial for complex parts like actuator shafts or sensor housings.

What are some specific examples of aerospace components made with Swiss machining?

Key applications include:

Jet Engine Components: Turbine blades, fuel injectors, compressor shafts (requiring heat resistance & tight tolerances).

Hydraulic & Pneumatic Systems: Fittings, valves (requiring precise threads, smooth surfaces, leak-free performance under pressure).

Fasteners: Bolts, screws (requiring fine threads, tight tolerances ±0.0003 in, vibration resistance).

Sensors & Connectors: Housings, electrical connectors (requiring intricate geometries, small diameters).

Is Swiss machining only suitable for prototypes or also for production?

Swiss machining is highly effective for both prototypes and high-volume production. Its automation, consistency, and speed make it ideal for manufacturing the thousands of identical, high-precision parts required in aircraft assembly. The reduced setup time is also advantageous for prototyping complex components quickly.