Swiss precision machining, also known as Swiss screw machining or Swiss-style turning, is a specialized manufacturing process designed to produce small, intricate components such as bushings, fasteners, fittings, and sleeves with exceptional accuracy. Originating in Switzerland to meet the demands of the watchmaking industry, this technique has evolved into a cornerstone of high-precision manufacturing across sectors like medical, aerospace, automotive, and electronics. This article provides a detailed examination of Swiss precision machining, its operational principles, applications, technical parameters, and specific focus on bushings, fasteners, fittings, and sleeves, offering a comprehensive resource for professionals seeking to understand this process.

Overview of Swiss Precision Machining

Swiss precision machining utilizes advanced computer numerical control (CNC) lathes to produce components with tight tolerances, often within a few microns. Unlike traditional machining, Swiss machining employs a sliding headstock and guide bushing system, which provides enhanced stability and precision during the machining process. The workpiece, typically bar stock, is fed through the guide bushing, allowing for precise cuts on long, slender parts like sleeves without deflection. This method is particularly effective for producing complex geometries and small-diameter components, making it a preferred choice for industries requiring high accuracy.

The process is highly automated, enabling simultaneous operations such as turning, milling, drilling, and threading. This multitasking capability reduces cycle times and enhances production efficiency, especially for high-volume manufacturing of components like fasteners and fittings. Swiss machining is renowned for its ability to handle a wide range of materials, including stainless steel, titanium, aluminum, brass, and engineering plastics like PEEK and nylon.

Key Components and Operational Mechanism

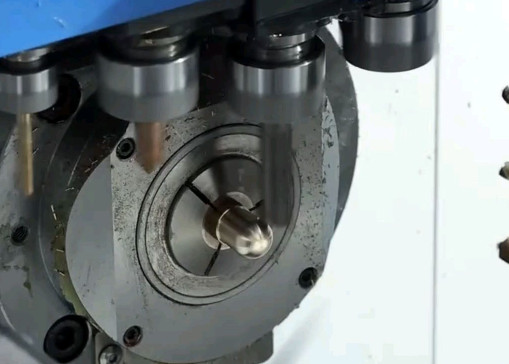

Swiss precision machining relies on several critical components that distinguish it from conventional CNC machining. The sliding headstock moves along the Z-axis, feeding the workpiece through a guide bushing that supports it close to the cutting tool. This minimizes vibration and ensures dimensional accuracy, particularly for parts with high aspect ratios like bushings and sleeves. The guide bushing, a hallmark of Swiss machining, maintains workpiece stability, reducing deflection even when machining delicate or thin components.

Swiss CNC machines are equipped with multiple spindle heads and a turret system, allowing for the simultaneous use of various cutting tools. These machines can perform complex operations in a single setup, eliminating the need for secondary processing. The automation of tool changes and synchronized spindle movements ensures consistent production with minimal human intervention, enhancing repeatability and reducing errors.

The following table outlines the key components of a typical Swiss CNC machine and their functions:

| Component | Function | Specification Example |

|---|---|---|

| Sliding Headstock | Moves workpiece along Z-axis for precise feeding | Travel distance: 100–250 mm |

| Guide Bushing | Supports workpiece to minimize vibration | Diameter range: 0.5–32 mm |

| Multi-Axis Turret | Holds multiple tools for simultaneous operations | Up to 12 axes, 10–20 tools |

| Main Spindle | Rotates workpiece at high speeds | Speed: 6,000–12,000 RPM |

| Sub-Spindle | Handles secondary operations | Speed: 5,000–10,000 RPM |

Technical Parameters and Capabilities

Swiss precision machining is defined by its ability to achieve exceptionally tight tolerances and high surface quality. Typical tolerances range from ±0.0001 inches (±2.54 microns) to ±0.001 inches (±25.4 microns), depending on the material and part complexity. Surface finishes can reach Ra values as low as 0.2 microns, often eliminating the need for post-processing. The process is capable of machining parts with diameters as small as 0.005 inches (0.127 mm) and lengths up to 5 inches (127 mm), though some machines can handle larger diameters up to 1.25 inches (32 mm).

The multi-axis capability of Swiss CNC machines, often up to 12 axes, allows for the production of intricate geometries, including threads, grooves, and complex contours. High-speed spindles, typically operating between 6,000 and 12,000 RPM, enable rapid material removal while maintaining precision. The machines can process a variety of materials, with specific parameters tailored to each:

- Stainless Steel: Cutting speed 50–150 m/min, feed rate 0.01–0.1 mm/rev

- Titanium: Cutting speed 20–60 m/min, feed rate 0.005–0.05 mm/rev

- Aluminum: Cutting speed 100–300 m/min, feed rate 0.02–0.15 mm/rev

- PEEK: Cutting speed 80–200 m/min, feed rate 0.01–0.08 mm/rev

These parameters ensure optimal tool life and surface quality while accommodating the unique properties of each material. For example, titanium requires lower cutting speeds to prevent tool wear, while aluminum allows for faster machining due to its softer composition.

Case Studies in Swiss Machining

Swiss precision machining is particularly well-suited for producing bushings, fasteners, fittings, and sleeves due to its ability to handle small, intricate parts with high precision. These components are critical in various industries, requiring tight tolerances and complex features to ensure functionality. Below is a detailed overview of each component type and its machining considerations:

Bushings: Bushings are cylindrical components used to reduce friction, guide moving parts, or provide alignment in assemblies. In Swiss machining, bushings are typically produced with inner diameters ranging from 0.5 mm to 20 mm and outer diameters up to 32 mm. Tolerances of ±0.0002 inches (±5 microns) are achievable, ensuring precise fitment in applications like automotive suspension systems or medical device assemblies. Materials such as brass, stainless steel, or PEEK are commonly used, with surface finishes reaching Ra 0.4 microns to minimize wear.

Fasteners: Fasteners, such as screws, bolts, and pins, are essential for joining components. Swiss machining excels at producing fasteners with intricate features like micro-threads or slotted heads, with thread pitches as fine as 0.2 mm. For example, medical bone screws may have diameters of 1–3 mm and require tolerances of ±0.0001 inches (±2.54 microns) to ensure compatibility with surgical tools. High-speed spindles and multi-axis capabilities allow for efficient threading and milling in a single setup, reducing production time.

Fittings: Fittings, such as hydraulic or pneumatic connectors, are critical for fluid or gas transfer systems. Swiss machining produces fittings with complex geometries, including internal channels or external threads, with diameters ranging from 2 mm to 25 mm. Tolerances of ±0.0003 inches (±7.62 microns) ensure leak-proof connections in aerospace and automotive applications. Materials like titanium or stainless steel are often selected for their corrosion resistance, with cutting speeds adjusted to 20–100 m/min to maintain tool life.

Sleeves: Sleeves are hollow, cylindrical components used to protect, align, or encase other parts. Swiss machining allows for the production of sleeves with wall thicknesses as low as 0.1 mm and lengths up to 100 mm. Tolerances of ±0.0002 inches (±5 microns) ensure precise alignment in applications like electronics or aerospace. Materials such as aluminum or engineering plastics are commonly used, with feed rates of 0.01–0.08 mm/rev to achieve smooth surface finishes.

Applications Across Industries

Swiss precision machining serves a wide range of industries, each benefiting from its ability to produce high-precision components like bushings, fasteners, fittings, and sleeves. Below are key applications:

Medical Industry

In the medical sector, Swiss machining is used to manufacture critical components such as bone screws, dental implants, surgical instruments, and orthopedic bushings. These parts require sub-micron precision to ensure compatibility with the human body and compliance with regulatory standards. For example, bone screws may have diameters as small as 1 mm with thread pitches of 0.25 mm, demanding exceptional accuracy.

Aerospace Industry

Aerospace applications include turbine blades, hydraulic fittings, and alignment sleeves. These parts must withstand extreme conditions while maintaining precise dimensions. Swiss machining produces components with tolerances as tight as ±0.0002 inches (±5 microns), ensuring reliability in high-stress environments.

Automotive Industry

The automotive sector relies on Swiss machining for fuel injector fittings, gears, and fasteners like pins and bolts. These parts require high precision to ensure vehicle performance and safety. For example, fuel injector nozzles may feature orifices as small as 0.1 mm, machined with consistent accuracy across high-volume production runs.

Electronics Industry

In electronics, Swiss machining produces connectors, pins, and sleeves for compact devices. These parts often require intricate features, such as micro-threads or slots, with tolerances below ±0.0005 inches (±12.7 microns) to ensure seamless integration into circuit boards.

Advantages of Swiss Precision Machining

Swiss precision machining offers several benefits that make it a preferred method for high-precision manufacturing of components like bushings, fasteners, fittings, and sleeves:

- High Precision and Accuracy: Tolerances as tight as ±0.0001 inches (±2.54 microns) ensure components meet exact specifications.

- Efficient Production: Simultaneous multi-axis operations reduce cycle times, enabling high-volume production with minimal setup changes.

- Versatility: Capable of machining a wide range of materials and complex geometries, suitable for diverse applications.

- Superior Surface Finish: Achieves Ra values as low as 0.2 microns, often eliminating the need for secondary finishing processes.

- Repeatability: Automated CNC systems ensure consistent quality across large production runs, minimizing variations.

These advantages translate to cost savings and improved product reliability, particularly for industries where precision is critical.

Material Compatibility and Selection

Material selection is a critical aspect of Swiss precision machining, as it impacts tool life, machining parameters, and part performance. The following table summarizes common materials and their suitability for Swiss machining:

| Material | Properties | Applications | Machining Considerations |

|---|---|---|---|

| Stainless Steel | Corrosion-resistant, durable | Medical implants, aerospace fittings | Moderate cutting speeds, high tool wear |

| Titanium | High strength, lightweight | Bone screws, aerospace sleeves | Low cutting speeds, specialized tools |

| Aluminum | Lightweight, easy to machine | Automotive fasteners, electronics | High cutting speeds, minimal tool wear |

| PEEK | High chemical resistance, biocompatible | Medical bushings, electronics sleeves | Moderate speeds, precise temperature control |

Selecting the appropriate material involves balancing performance requirements with machining feasibility. For example, titanium’s strength makes it ideal for aerospace sleeves, but its hardness requires specialized tooling and slower cutting speeds to maintain precision.

Quality Control and Inspection

Quality control is integral to Swiss precision machining, ensuring components like bushings, fasteners, fittings, and sleeves meet stringent specifications. Advanced inspection equipment, such as coordinate measuring machines (CMMs) and optical comparators, verifies dimensional accuracy to within ±0.0001 inches (±2.54 microns). Surface profilometers measure finish quality, ensuring compliance with industry standards like ISO 9001. In-process monitoring, including real-time feedback from CNC systems, detects deviations and ensures consistency across production runs.

Rigorous testing protocols, such as hardness testing and material composition analysis, confirm that parts meet performance requirements. For medical and aerospace applications, traceability and documentation are critical to comply with regulatory standards.

Conclusion

Swiss precision machining is a highly specialized manufacturing process that delivers unmatched accuracy and efficiency for small, intricate components like bushings, fasteners, fittings, and sleeves. Its unique combination of sliding headstock, guide bushing, and multi-axis CNC technology enables the production of complex parts with tight tolerances and excellent surface finishes. With applications spanning medical, aerospace, automotive, and electronics industries, Swiss machining remains a critical technology for high-precision manufacturing. By leveraging advanced equipment, precise parameters, and robust quality control, this process ensures reliable, high-quality components that meet the demands of modern industries.