Titanium alloy parts are indispensable in numerous high-performance industries due to their exceptional properties, such as high strength, durability, and resistance to extreme conditions. However, the cost of these parts is often substantial. This article analyzes the primary reasons behind the high price of titanium alloy parts, including production costs, manufacturing complexity, market dynamics, and their performance value across various industries.

High Production Costs

The production costs of titanium alloy parts are primarily driven by expensive raw materials and intricate manufacturing processes. Titanium is extracted from minerals like ilmenite or rutile through energy-intensive methods, such as the Kroll process, which requires high temperatures and specialized equipment. Refining titanium into an industrially usable form demands stringent purity control, further increasing costs.

Once extracted, titanium is typically alloyed with elements like aluminum, vanadium, or molybdenum to enhance its mechanical properties, such as strength, corrosion resistance, and heat tolerance. These alloying processes, along with subsequent steps like casting, forging, and heat treatment, necessitate advanced equipment such as vacuum arc furnaces or precision forging presses. The acquisition and maintenance of this equipment are costly. Moreover, the raw materials themselves are expensive due to their scarcity and the complexity of extraction, keeping production costs high.

Complex Manufacturing Processes

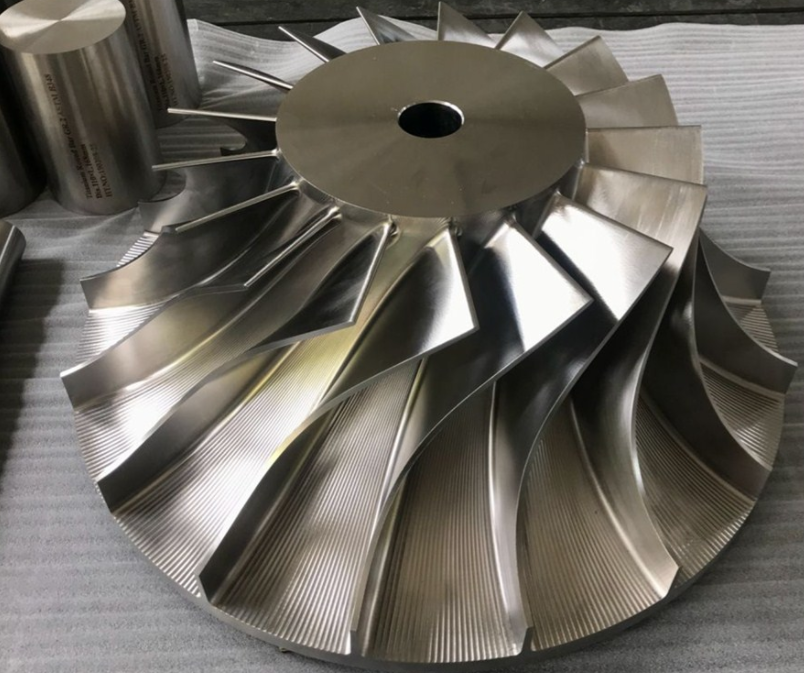

Titanium alloy parts often require sophisticated manufacturing processes to meet the stringent demands of high-performance applications. These parts must adhere to precise tolerances to ensure reliability in harsh environments. For instance, in industries like automotive, medical devices, or energy, the dimensional accuracy of parts directly impacts safety and functionality.

The manufacturing process typically involves multiple stages, including milling, turning, and grinding, usually performed on computer numerical control (CNC) machines. These machines are not only expensive to purchase and maintain but also require highly trained technicians to operate. After machining, parts undergo rigorous quality checks using non-destructive testing (NDT) methods like ultrasonic or X-ray inspections to ensure structural integrity. These labor-intensive and equipment-dependent procedures significantly contribute to the overall cost of titanium alloy parts.

Market Dynamics and Economies of Scale

Titanium alloy parts are commonly used in specialized sectors such as high-performance automotive components, medical implants, or industrial equipment. Unlike mass-produced consumer goods, these parts are typically produced in smaller quantities due to their niche applications. This lower production volume limits the benefits of economies of scale, which are crucial for reducing per-unit costs.

Additionally, the unique requirements of titanium alloy parts mean that production facilities are geared toward low-volume, high-precision manufacturing rather than high-throughput production. This setup demands expertise in metallurgy, precision engineering, and industry certifications, creating high barriers to entry and limiting the number of capable manufacturers. Consequently, fixed costs such as research and development, equipment, and quality assurance are spread across fewer units, driving up the cost per part.

Performance Advantages Justify Costs

Despite their high cost, titanium alloy parts remain irreplaceable in many industries due to their superior performance. Titanium alloys offer an excellent strength-to-weight ratio, making them ideal for applications where weight reduction is critical without compromising strength. Their resistance to corrosion and extreme temperatures ensures reliability in harsh environments, such as chemical processing plants, offshore oil rigs, or high-performance engines.

Compared to alternatives like steel or aluminum, titanium alloys provide unmatched durability and performance, which are essential for ensuring the safety and efficiency of critical systems. These characteristics make titanium alloys a necessary choice for high-performance applications, offering long-term stability and reliability even at a premium price.

Conclusion

The high cost of titanium alloy parts stems from a combination of expensive raw materials, complex manufacturing processes, and limited market demand. The energy-intensive extraction and alloying of titanium, coupled with precision machining and stringent quality control, result in significant production expenses. Additionally, the specialized nature of their applications across industries restricts economies of scale. However, the exceptional performance of titanium alloys—such as high strength, durability, and resistance to extreme conditions—makes them indispensable for many high-performance applications, ensuring reliability and efficiency in demanding environments.