5-axis CNC machining offers significant benefits for shell processing, enabling manufacturers to produce complex, high-precision components efficiently. This article explores the technical advantages, supported by detailed parameters and practical applications, to demonstrate its value in modern manufacturing.

Understanding 5-Axis Machining and Shell Processing

5-axis machining involves a CNC machine moving a cutting tool or workpiece along five different axes simultaneously: three linear axes (X, Y, Z) and two rotational axes (A, B, or C). This allows the tool to approach the workpiece from virtually any direction, making it ideal for complex geometries like shells, which are often used in aerospace, automotive, and medical industries.

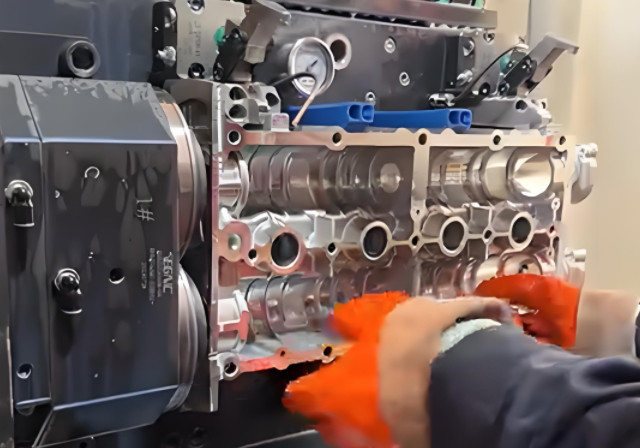

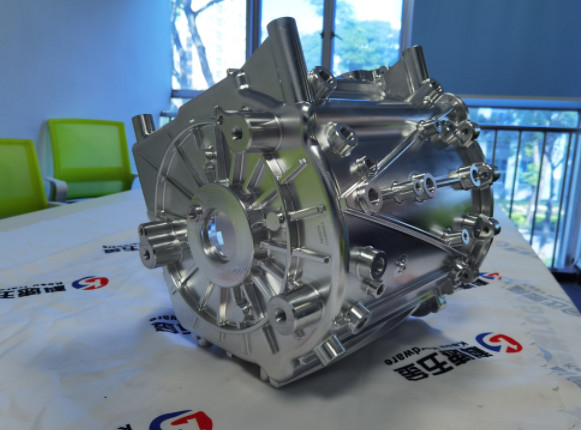

Shell processing refers to the machining of thin-walled, complex-shaped components, such as turbine housings, pump casings, or medical device enclosures. These parts require high precision, tight tolerances (e.g., ±0.005 mm), and smooth surface finishes (Ra 0.8–0.2 μm). Traditional 3-axis machining often struggles with these requirements due to limited tool access and multiple setups.

Key Advantages of 5-Axis Machining in Shell Processing

The following sections detail the primary benefits of 5-axis machining for shell processing, emphasizing technical precision and practical outcomes.

Enhanced Precision and Accuracy

5-axis machining achieves superior precision by allowing continuous tool contact with the workpiece at optimal angles. For shell components, which often feature curved surfaces and deep cavities, this ensures consistent material removal and adherence to tight tolerances. For example, aerospace turbine shells require dimensional accuracy within ±0.01 mm to ensure performance and safety.

The use of shorter cutting tools, enabled by the machine’s ability to tilt and rotate, reduces tool deflection. A shorter tool (e.g., 50 mm vs. 100 mm in 3-axis setups) experiences less vibration, improving surface finish quality (Ra 0.4 μm vs. Ra 1.6 μm in 3-axis). This is critical for shells where surface imperfections can affect fluid dynamics or structural integrity.

Reduced Setup Time and Increased Efficiency

One of the most significant advantages of 5-axis machining is the ability to machine multiple surfaces in a single setup. In 3-axis machining, shell components often require repositioning, which involves unclamping, rotating, and reclamping the workpiece. Each setup introduces potential alignment errors (up to 0.02 mm) and increases cycle time.

In contrast, a 5-axis machine can access five of the six faces of a part without repositioning. For a pump casing with multiple angled features, a 5-axis setup can reduce cycle time by 30–50% (e.g., from 120 minutes to 60 minutes). This efficiency is particularly valuable in high-mix, low-volume production, common in shell processing for custom enclosures.

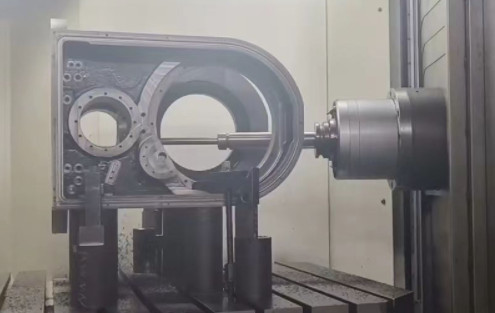

Ability to Machine Complex Geometries

Shell components often feature intricate shapes, such as freeform surfaces, undercuts, or deep pockets, which are challenging for 3-axis machines. 5-axis machining excels in these applications by allowing the tool to follow complex toolpaths. For example, a medical device shell with a spherical inner surface can be machined in one operation, maintaining a uniform wall thickness of 1.5 mm.

The additional rotational axes enable the tool to maintain a tangential orientation to the surface, ensuring consistent cutting conditions. This is critical for parts like automotive transmission housings, where complex contours must meet geometric dimensioning and tolerancing (GD&T) requirements, such as profile tolerances of 0.03 mm.

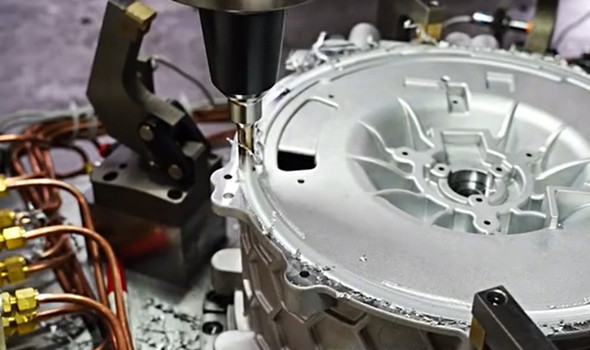

Improved Surface Finish

Surface finish is a critical parameter in shell processing, as it affects performance, aesthetics, and durability. 5-axis machining enhances surface quality by using shorter, more rigid tools and optimized toolpaths. For instance, a 5-axis machine can achieve a surface roughness of Ra 0.2 μm on a titanium shell, compared to Ra 0.8 μm with a 3-axis machine.

Additionally, the continuous motion of the tool in 5-axis machining minimizes tool marks and chatter, common issues in 3-axis setups. This is particularly beneficial for shells used in fluid-handling systems, where smooth surfaces reduce turbulence and improve efficiency.

Cost-Effectiveness in Production

While 5-axis machines have higher initial costs (approximately $200,000–$500,000 vs. $50,000–$100,000 for 3-axis), they offer long-term cost savings. The reduction in setups lowers labor costs, as fewer manual interventions are needed. For a batch of 100 shell components, a 5-axis machine can save 20–30 hours of labor compared to a 3-axis setup.

Moreover, the ability to use shorter tools extends tool life by 25–40%, reducing tooling costs. For example, a carbide end mill used in 5-axis machining may last 200 hours, compared to 150 hours in 3-axis due to reduced vibration and heat generation.

Practical Applications in Shell Processing

5-axis machining is widely used in industries requiring high-precision shell components. The following table summarizes key applications and their specific requirements:

| Industry | Shell Component | Key Requirements | 5-Axis Advantage |

|---|---|---|---|

| Aerospace | Turbine Housing | ±0.01 mm tolerance, Ra 0.4 μm | Single-setup machining of curved surfaces |

| Automotive | Transmission Casing | Complex contours, ±0.02 mm | Reduced setups, improved GD&T compliance |

| Medical | Device Enclosure | Ra 0.2 μm, 1.5 mm wall thickness | High-precision freeform surfaces |

| Energy | Pump Casing | Deep cavities, ±0.015 mm | Access to hard-to-reach features |

Aerospace Industry

In aerospace, 5-axis machining is critical for producing turbine housings and compressor shells. These components require intricate geometries and tight tolerances to withstand high temperatures and pressures. A 5-axis machine can produce a turbine housing with a diameter of 300 mm and wall thickness of 2 mm in a single setup, ensuring dimensional accuracy and surface quality.

Automotive Industry

Automotive manufacturers use 5-axis machining for transmission casings and engine covers. These shells often have multiple angled features and require high throughput. A 5-axis machine can reduce production time for a transmission casing from 90 minutes to 50 minutes, improving efficiency in high-volume production.

Medical Industry

Medical device enclosures, such as those for imaging equipment, demand smooth surfaces and precise dimensions. 5-axis machining ensures consistent wall thickness and eliminates the need for secondary finishing, reducing production costs and lead times.

Energy Sector

In the energy industry, pump casings and valve bodies require deep cavities and complex internal features. 5-axis machining allows tools to access these areas without repositioning, maintaining accuracy and reducing cycle times.

Technical Parameters and Performance Metrics

To quantify the advantages of 5-axis machining, the following table compares key performance metrics with 3-axis machining for a typical shell component (e.g., a pump casing with a 200 mm diameter):

| Parameter | 5-Axis Machining | 3-Axis Machining |

|---|---|---|

| Setup Time | 10 minutes | 30–60 minutes |

| Cycle Time | 60 minutes | 100–120 minutes |

| Tolerance | ±0.005 mm | ±0.02 mm |

| Surface Finish | Ra 0.2–0.4 μm | Ra 0.8–1.6 μm |

| Tool Life | 200 hours | 150 hours |

Considerations for Implementing 5-Axis Machining

While 5-axis machining offers clear advantages, manufacturers must consider certain limitations to ensure successful implementation:

- Programming Complexity: 5-axis machining requires advanced CAM software (e.g., Autodesk Fusion, Mastercam) to generate toolpaths. Skilled programmers are essential to optimize machining strategies and avoid collisions.

- Operator Expertise: Operating a 5-axis machine demands a deep understanding of CNC programming and spatial awareness. Training programs can take 3–6 months to develop proficient operators.

- Material Constraints: Shell processing often involves hard materials like titanium or stainless steel, which require specialized tools and cutting parameters (e.g., spindle speeds of 10,000–20,000 RPM).

Conclusion

5-axis machining revolutionizes shell processing by offering unmatched precision, efficiency, and versatility. Its ability to handle complex geometries, reduce setups, and improve surface finishes makes it indispensable for industries like aerospace, automotive, medical, and energy. By leveraging advanced toolpaths and shorter cutting tools, manufacturers can achieve tight tolerances (±0.005 mm) and superior surface quality (Ra 0.2 μm), while reducing cycle times by up to 50%. Despite higher initial costs and programming complexity, the long-term benefits of 5-axis machining justify its adoption for high-precision shell components.