Aluminum and stainless steel are cornerstone materials in engineering, manufacturing, and construction due to their unique properties. This article provides a systematic, data-driven comparison of their composition, mechanical properties, corrosion resistance, thermal and electrical conductivity, processing and fabrication, cost, and applications. The analysis aims to guide engineers and manufacturers in selecting the optimal material for specific projects, emphasizing technical parameters and practical considerations.

Composition and Elemental Makeup

Aluminum, a lightweight, non-ferrous metal, is extracted from bauxite via electrolysis. Commercially pure aluminum (99-99.6% purity) is often alloyed with elements like copper, magnesium, silicon, or zinc to enhance strength, corrosion resistance, or workability. Common alloys include 6061 (magnesium and silicon for strength and weldability) and 5052 (marine-grade for corrosion resistance). Stainless steel, an iron-based alloy, contains at least 10.5% chromium for corrosion resistance, with additions like nickel, molybdenum, or carbon tailoring specific properties. Grades are categorized as austenitic (e.g., 304, 316), ferritic (e.g., 430), or martensitic (e.g., 440C). For example, 316 stainless steel includes 2-3% molybdenum, improving resistance to chlorides.

Mechanical Properties

Mechanical properties, including tensile strength, yield strength, and hardness, determine a material’s suitability for structural applications. Stainless steel generally offers higher strength, while aluminum’s lower density provides a superior strength-to-weight ratio.

| Property | Aluminum (6061-T6) | Stainless Steel (304) |

|---|---|---|

| Tensile Strength (MPa) | 310 | 505-515 |

| Yield Strength (MPa) | 240 | 170-215 |

| Density (g/cm³) | 2.7 | 7.9-8.0 |

| Young’s Modulus (GPa) | 69 | 193-200 |

Stainless steel’s tensile strength (505-515 MPa for 304 vs. 310 MPa for 6061-T6 aluminum) suits high-stress applications like bridges or machinery. Aluminum’s density (2.7 g/cm³ vs. 7.9-8.0 g/cm³ for stainless steel) yields a strength-to-weight ratio of approximately 99 versus 63, favoring aluminum in aerospace and automotive components. Hardness varies: martensitic stainless steel (e.g., 440C) is harder, ideal for cutting tools, while aluminum alloys are softer, aiding machinability but reducing wear resistance. Stainless steel’s fatigue strength (250 MPa for 304 vs. 96.5 MPa for 6061) supports cyclic loading applications like springs.

Corrosion Resistance

Both materials resist corrosion, but their performance varies by environment. Aluminum’s natural oxide layer protects against rust, suitable for outdoor use, but degrades in acidic or alkaline conditions, risking pitting. Marine-grade alloys like 5052 improve chloride resistance but are less robust than stainless steel in harsh settings. Stainless steel’s chromium forms a passive oxide layer, with grades like 316 (containing molybdenum) excelling in marine and chemical environments. Its non-porous nature enhances hygiene, making it ideal for food processing and medical equipment.

Thermal and Electrical Conductivity

Aluminum’s superior conductivity suits applications requiring heat or energy transfer, while stainless steel’s lower conductivity benefits thermal insulation.

| Property | Aluminum (Pure) | Stainless Steel (304) |

|---|---|---|

| Thermal Conductivity (W/m·K at 20°C) | 237 | 10-30 |

| Electrical Conductivity (% of Copper) | 61 | 3-5 |

| Melting Point (°F) | 1220 | 2550 |

Aluminum’s thermal conductivity (237 W/m·K) is ten times higher than stainless steel’s (10-30 W/m·K), ideal for heat sinks and radiators. Its electrical conductivity (61% of copper) suits power lines, while stainless steel’s lower conductivity (3-5%) fits applications like cookware handles. Stainless steel’s higher melting point (2550°F vs. 1220°F) ensures stability in high-temperature environments like aircraft exhausts.

Workability and Fabrication

Workability and fabrication processes significantly impact manufacturing efficiency, cost, and material suitability. This section details machining, forming, welding, and surface treatments for aluminum and stainless steel, highlighting their processing characteristics.

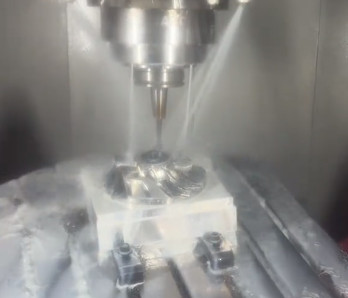

Machining: Aluminum’s lower hardness (e.g., 95 Brinell for 6061-T6 vs. 123-200 Brinell for 304 stainless steel) and high chip-forming tendency make it easier to machine. High-speed steel or carbide tools can machining aluminum at speeds up to 600 m/min, reducing tool wear and machining time. Common operations include milling, drilling, and turning, with aluminum producing long, continuous chips that require effective chip management. Stainless steel, particularly austenitic grades like 304, is tougher to machine due to its work-hardening properties, where cutting generates heat that hardens the material (up to 40% increase in hardness). Machining speeds are lower (100-200 m/min), and tools like cobalt-alloyed steel or coated carbide are needed to withstand wear. Martensitic grades like 440C are even harder, increasing tool costs and machining time.

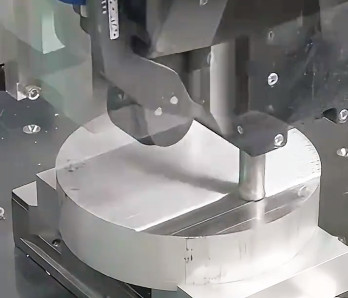

Forming: Aluminum’s high ductility and low yield strength allow easy forming into complex shapes like extrusions, sheets, or deep-drawn components. For example, 5052 aluminum can be cold-formed with minimal springback, ideal for automotive panels. However, its lower strength limits formability under high stress. Stainless steel’s higher strength and lower ductility make forming more challenging, especially for martensitic grades, which are prone to cracking. Austenitic stainless steel (e.g., 304) can be formed into shapes like tubes or sinks but requires higher forces (e.g., 20-30% more than aluminum) and specialized equipment to prevent work-hardening-induced defects.

Welding: Aluminum welding requires careful control due to its high thermal conductivity and low melting point, which can cause distortion or burn-through. Techniques like Tungsten Inert Gas (TIG) or Metal Inert Gas (MIG) welding are used, with filler materials like 4043 or 5356 alloys matching the base metal. Preheating is rarely needed, but oxide removal is critical to avoid weld imperfections. Stainless steel, with lower thermal conductivity, is easier to weld, particularly austenitic grades like 304 or 316, using TIG, MIG, or stick welding. However, post-weld heat treatment may be required to restore corrosion resistance in the heat-affected zone, especially for 316 in corrosive environments. Martensitic grades are less weldable, risking cracks without preheating (200-300°C).

Surface Treatments: Aluminum often undergoes anodizing, which thickens its oxide layer (10-25 µm) to enhance corrosion resistance and wear properties. Chemical conversion coatings or powder coating improve aesthetics and durability, common in architectural panels. Stainless steel requires less surface treatment due to its inherent corrosion resistance but may be passivated (using nitric acid) to remove surface contaminants or polished for hygiene in food and medical applications. Electropolishing reduces surface roughness by 50%, improving cleanability for 316 stainless steel in pharmaceutical equipment.

Aluminum’s ease of machining and forming suits high-volume production, while stainless steel’s durability supports applications requiring minimal post-processing maintenance. However, stainless steel’s higher processing costs due to tool wear and slower speeds must be considered.

Cost Considerations

Aluminum is generally less expensive due to its abundance (8% of Earth’s crust) and lower processing energy requirements. By weight, aluminum costs more, but its lower density reduces material volume needed, cutting overall costs by ~30% compared to stainless steel. Stainless steel’s higher cost reflects its chromium and nickel content and complex processing, especially for grades like 316. Fabrication costs further increase for stainless steel due to machining and forming challenges, while aluminum’s ease of processing lowers production expenses in automotive or consumer goods manufacturing.

Applications and Suitability

Aluminum’s lightweight and conductivity suit:

- Aerospace: Fuselages and engine parts (e.g., 7075 aluminum).

- Automotive: Panels and radiators for fuel efficiency.

- Electronics: Heat sinks and conductors.

- Packaging: Cans and foils (e.g., 1100 aluminum).

Stainless steel’s strength and corrosion resistance fit:

- Construction: Bridges and railings (e.g., 304).

- Medical: Surgical tools for hygiene.

- Food Processing: Appliances for corrosion resistance.

- Marine: Ship fittings (e.g., 316).

Both are highly recyclable, with aluminum at 75% reuse in the U.S. and stainless steel retaining properties post-recycling.

Limitations and Considerations

Aluminum’s corrosion susceptibility in acidic or saline environments requires treatments like anodizing to prevent failure. Its lower strength limits high-stress applications. Stainless steel’s weight restricts use in mass-sensitive designs, and its machining difficulty increases costs. Welding challenges include aluminum’s distortion risk and stainless steel’s potential loss of corrosion resistance at welds. Proper alloy selection and processing techniques are critical to mitigate these issues.

Conclusion

Aluminum and stainless steel offer distinct advantages: aluminum’s lightweight and ease of processing suit weight-sensitive, high-volume applications, while stainless steel’s strength and corrosion resistance excel in demanding environments. Understanding their properties, processing requirements, and limitations enables informed material choices for optimal performance and cost.

FAQ: Aluminum vs. Stainless Steel

What are the key differences in composition between aluminum and stainless steel?

Aluminum is a non-ferrous metal (no iron) with high purity (99-99.6% pure) in its commercial form, often alloyed with copper, magnesium, or silicon to enhance properties (e.g., 6061 with magnesium and silicon for strength).

Stainless steel is an iron-based alloy containing at least 10.5% chromium (for corrosion resistance) and may include nickel, molybdenum, or carbon. Grades like 304 (austenitic) or 316 (with molybdenum for chloride resistance) are tailored for specific uses.

Which material is stronger: aluminum or stainless steel?

Stainless steel generally has higher tensile strength. For example, 304 stainless steel has a tensile strength of 505-515 MPa, compared to 310 MPa for 6061-T6 aluminum.

However, aluminum has a superior strength-to-weight ratio due to its lower density (2.7 g/cm³ vs. 7.9-8.0 g/cm³ for stainless steel), making it ideal for weight-sensitive applications like aerospace.

Which is easier to machine and fabricate?

Aluminum is easier to process due to its lower hardness and ductility:

Machining: Can be cut at speeds up to 600 m/min with minimal tool wear.

Forming: Easily shaped into extrusions or sheets (e.g., automotive panels) with low springback.

Welding: Requires TIG/MIG techniques but little preheating (oxide removal is critical).

Stainless steel (especially austenitic grades like 304) is harder to machine (slower speeds, 100-200 m/min) and form (needs higher forces) due to work-hardening. Welding is simpler but may require post-treatment to restore corrosion resistance.

Which is more cost-effective?

Aluminum is generally cheaper overall:

Its abundance and lower processing energy reduce material costs. While pricier by weight, its lower density cuts volume needs, lowering total costs by ~30% compared to stainless steel.

Stainless steel’s higher cost reflects chromium/nickel content and complex processing (e.g., 316 is more expensive than 304). Fabrication costs are also higher due to machining challenges.

What are their typical applications?

Aluminum: Aerospace (fuselages), automotive (panels, radiators), electronics (heat sinks), packaging (cans).

Stainless Steel: Construction (bridges, railings), medical (surgical tools), food processing (appliances), marine (ship fittings, 316 grade).